NORD Drivesystems BU0180 User Manual

Page 111

6 Parameterisation

BU 0180 GB-0914

Pre-series version

111

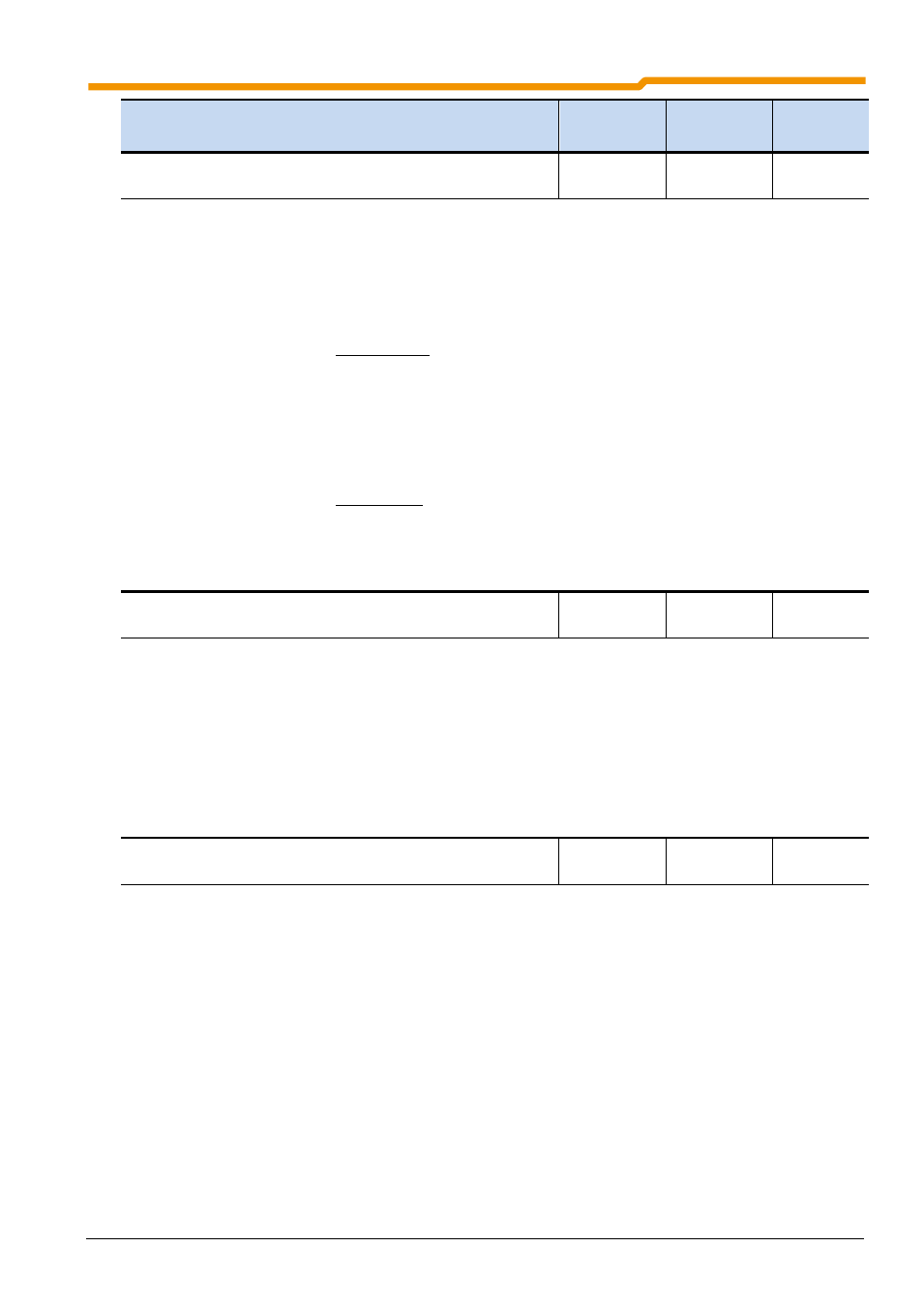

Parameter

{Factory setting}

Setting value / Description / Note

Device

Supervisor

Parameter

set

P503

Leading func. output

(Master function output)

S

0 ... 3

{ 0 }

For master-slave applications this parameter specifies on which bus system the master

transmits the control word and the master values (P502) for the slave. On the slave, parameters

(P509), (P510), (P546 ) define the source from which the slave obtains the control word and the

master values from the master and how these are to be processed by the slave.

Specification of the communication mode on the system bus for ParameterBox and NORD CON.

0 = Off

No control word and master value

output.

If no BUS option (e.g. SK xU4-IOE)

is connected to the system bus, only

the device directly connected to the

ParameterBox or NORD CON is

visible.

1 = CANopen (system bus)

Control word and master values are

transferred to the system bus.

If no bus option (e.g. SK xU4-IOE) is

connected to the system bus, only

the device directly connected to the

ParameterBox or NORD CON is

visible.

2 = System bus active

No control word and master value

output.

All FIs connected to the system bus

are visible in the ParameterBox or

NORD CON, even if no bus option is

connected. Prerequisite: all FIs must be

set to this mode.

3 = System bus active

control word and master value

output.

All FIs connected to the system bus

are visible in the ParameterBox or

NORD CON, even if no bus option is

connected. Prerequisite: all other FIs

must be set to mode { 2 } "System bus

active"

P504

Pulse frequency

(Pulse frequency)

S

3.0 ... 16.0 kHz

{ 6.0 }

The internal pulse frequency for actuating the power component can be changed with this

parameter. A higher setting reduces motor noise, but leads to increased EMC emissions and

reduction of the possible motor nominal torque.

NOTE:

The radio interference suppression limiting curve C1 according to EN55011 is

complied with at a setting of 6.0kHz on condition that the wiring guidelines are

complied with. For further details, see Section 9.3.3 (EMC).

NOTE:

Raising the pulse frequency leads to a reduction of the possible output current,

depending on the time (I

2

t curve). For further details, see Section 9.4 Reduced

P505

Abs. Minimum frequency

(Absolute minimum frequency)

S

P

0.0 ... 10.0 Hz

{ 2.0 }

Gives the frequency value that cannot be undershot by the FI. If the setpoint becomes smaller

than the absolute minimum frequency, the FI switches off or changes to 0.0 Hz.

At the absolute minimum frequency, braking control (P434) and the setpoint delay (P107) are

actuated. If a setting value of "Zero" is selected, the brake relay does not switch during

reversing.

When controlling lift equipment without speed feedback, this value should be set to a minimum

of 2 Hz. From 2 Hz, the current control of the FI operates and a connected motor can supply

sufficient torque.

NOTE:

Output frequencies < 4.5 Hz result in a reduced current overload capacity.

For further details, see Section 9.4 power derating.