Ethernet/ip™, pccc and modbus tcp communications, Ethernet led indicators – Watlow EZ-ZONE PM Integrated Controller User Manual

Page 38

Watlow EZ-ZONE

®

PM Integrated Controller

•

35

•

Chapter 2 Install and Wire

Warning:

Óç

Use National Electric (NEC) or other

country-specific standard wiring and

safety practices when wiring and

connecting this controller to a power

source and to electrical sensors or

peripheral devices. Failure to do so

may result in damage to equipment

and property, and/or injury or loss

of life.

Note:

Maximum wire size termination and

torque rating:

• 0.0507 to 3.30 mm

2

(30 to 12

AWG) single-wire termination or

two 1.31 mm

2

(16 AWG)

• 0.8 Nm (7.0 lb.-in.) torque

Note:

Adjacent terminals may be labeled

differently, depending on the model

number.

Note:

To prevent damage to the control-

ler, do not connect wires to unused

terminals.

Note:

Maintain electrical isolation between

analog input 1, digital input-outputs,

switched dc/open collector outputs

and process outputs to prevent

ground loops.

Note:

The control output common termi-

nal and the digital common terminal

are referenced to different voltages

and must remain isolated.

Note:

This Equipment is suitable for use in

CLASS I, DIVISION 2, Groups A, B,

C and D or Non-Hazardous locations

only. Temperature Code T4A

Warning:

ç

Explosion Hazard - Dry contact clo-

sure Digital Inputs shall not be used

in Class I Division 2 Hazardous Loca-

tions unless switch used is approved

for this application.

Warning:

ç

Explosion Hazard – Substitution of

component may impair suitability

for CLASS I, DIVISION 2.

Warning:

ç

Explosion Hazard - Do not discon-

nect while the circuit is live or

unless the area is known to be free

of ignitable concentrations of flam-

mable substances.

EIA-232/485 Modbus RTU Communications

485 common

485 T+/R+

CB

CA

CC

CB

CA

C5

C3

C2

Slot B, E

485 T-/R-

485 T+/R+

485 T-/R-

232 common

232 (TX) to DB9 pin 2 (RD)

232 (RD) to DB9 pin 3 (TX)

• Wire T-/R- to the A termi-

nal of the EIA-485 port.

• Wire T+/R+ to the B termi-

nal of the EIA-485 port.

• Wire common to the com-

mon terminal of the EIA-

485 port.

• Do not route network wires

with power wires. Connect

network wires in daisy-

chain fashion when con-

necting multiple devices in

a network.

• A termination resistor may

be required. Place a 120 Ω

resistor across T+/R+ and

T-/R- of last controller on

network.

• Do not wire to both the

EIA-485 and the EIA-232

pins at the same time.

• Two EIA-485 terminals of

T/R are provided to assist

in daisy-chain wiring.

• Do not connect more than

one EZ-ZONE PM control-

ler on an EIA-232 network.

• Do not connect more than

16 EZ-ZONE controllers on

a Standard Bus EIA-485

network.

• Maximum number of EZ-

ZONE controllers on a

Modbus network is 247.

• maximum EIA-232 network

length: 15 meters (50 feet)

• maximum EIA-485 network

length: 1,200 meters (4,000

feet)

• 1/8th unit load on EIA-485

bus.

• Communications instance 2

Slot B

PM [6] _ _ _ _ - [2] _ _ _ _ _ _

Slot E

PM [4,8,9] _ _ _ _ - [2] _ _ _

_ _ _

Modbus-IDA

Terminal

EIA/TIA-485

Name

Watlow Terminal

Label

Function

DO

A

CA or CD

T-/R-

D1

B

CB or CE

T+/R+

common

common

CC or CF

common

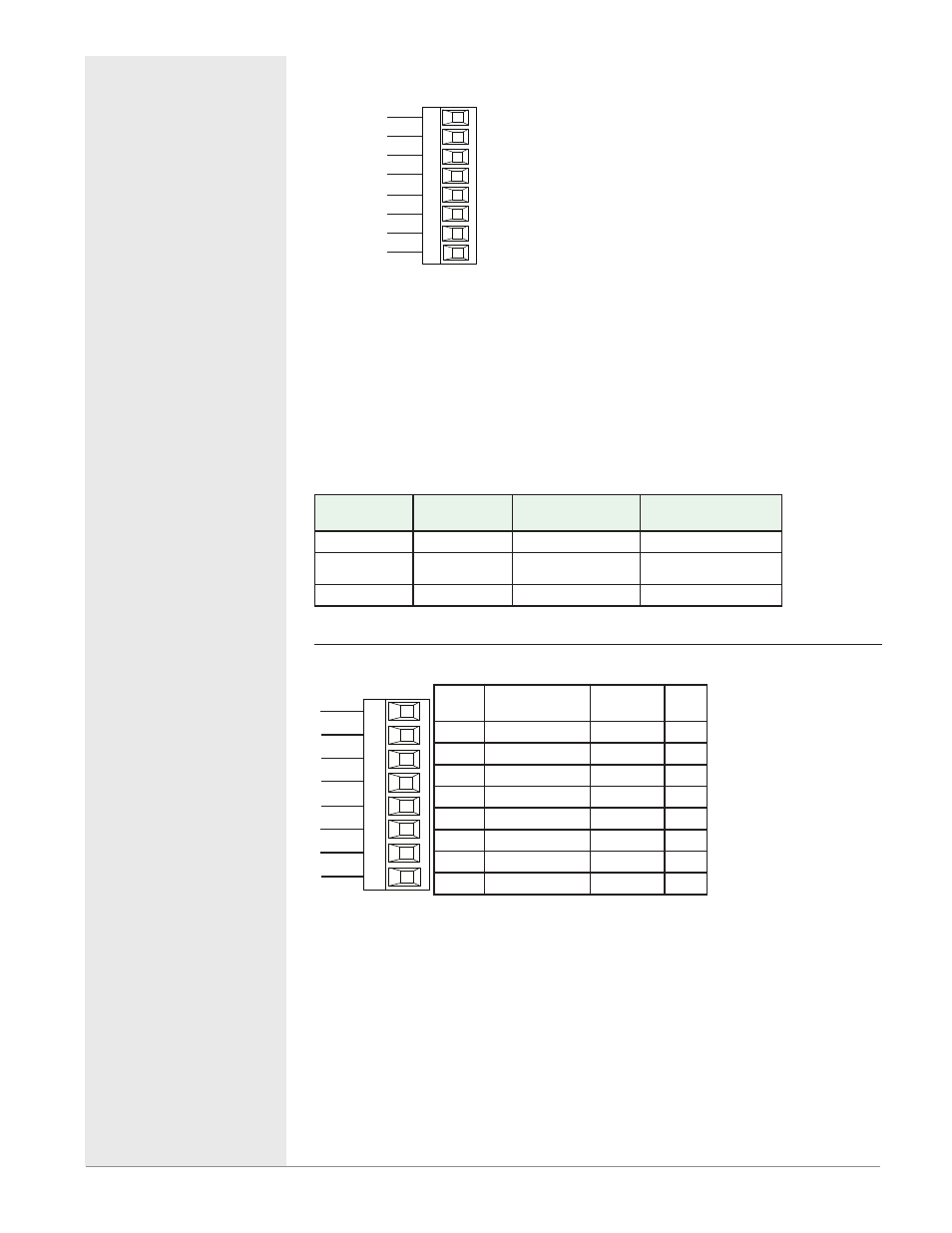

EtherNet/IP™, PCCC and Modbus TCP Communications

receive -

unused

E8

E7

E6

E5

E4

E3

E2

E1

Slot B, E

unused

unused

unused

receive +

transmit -

transmit +

RJ-45

pin

T568B wire

color

Signal

Slot

B, E

8

brown

unused

E8

7

brown & white

unused

E7

6

green

receive -

E6

5

white & blue

unused

E5

4

blue

unused

E4

3

white & green

receive +

E3

2

orange

transmit -

E2

1

white & orange

transmit + E1

EtherNet/IP™ and Modbus TCP communica-

tions to connect with a 10/100 switch .

• Do not route network

wires with power wires.

• Connect one Ethernet

cable per controller to

a 10/100 Mbps ethernet

switch. Both Modbus TCP

and EtherNet/IP™ are

available on the network.

• Communications instance

2

Slot B

PM [6] _ _ _ _ - [3] _ _ _ _

_ _

Slot E

PM[4,8,9] _ _ _ _ - [3] _ _ _

_ _ _

Note:

When changing the fixed IP address cycle module power for new address to

take effect.

Ethernet LED Indicators

Viewing the control from the front and then looking on top four LEDs can be

seen aligned vertically front to back. The LEDs are identified accordingly:

closest to the front reflects the Network (Net) Status, Module (Mod) Status is

next, Activity status follows and lastly, the LED closest to the rear of the con-

trol reflects the Link status.