Inputs, Calibration offset, Calibration – Watlow EZ-ZONE PM Integrated Controller User Manual

Page 128

Watlow EZ-ZONE

®

PM Integrated Controller

•

125

•

Chapter 9 Features

ç

WARNING! During autotuning, the controller sets the output to 100 percent and attempts to drive the Process Value toward

the set point . Enter a set point and heat and cool power limits that are within the safe operating limits of your system .

Inputs

Calibration Offset

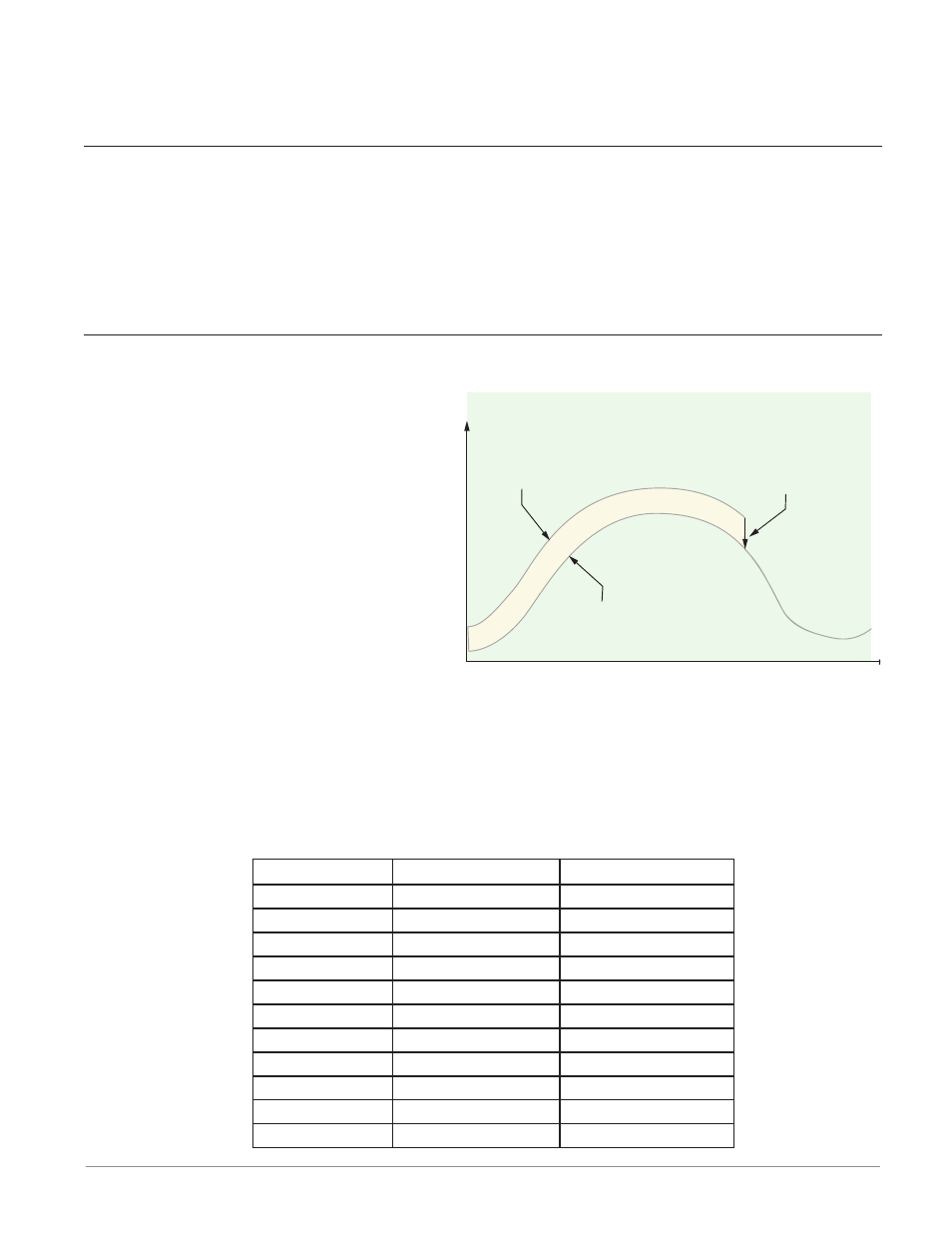

Calibration offset allows a device to compensate for an inaccurate sensor, lead resistance or other factors that

affect the input value. A positive offset increases the input value, and a negative offset decreases the input

value.

The input offset value can be viewed or changed with Calibration Offset [`i;CA] (Operations Page, Analog

Input Menu).

Calibration

Before performing any calibration procedure, verify that the displayed readings are not within published

specifications by inputting a known value from a

precision source to the analog input. Next, sub-

tract the displayed value with the known value

and compare this difference to the published ac-

curacy range specification for that type of input.

Use of the Calibration Offset [`i;CA] param-

eter found in the Operations Page [oPEr] , Ana-

log Input Menu [``Ai] shifts the readings across

the entire displayed range by the offset value.

Use this parameter to compensate for sensor er-

ror or sensor placement error. Typically this val-

ue is set to zero.

Equipment required while performing cali-

bration: Obtain a precision source for millivolts,

volts, milliamperes or resistance depending on

the sensor type to be calibrated. Use copper wire

only to connect the precision source to the con-

troller’s input. Keep leads between the precision source and controller as short as possible to minimize error.

In addition, a precision volt/ohm meter capable of reading values to 4 decimal places or better is recommend-

ed. Prior to calibration, connect this volt/ohm meter to the precision source to verify accuracy.

Actual input values do NOT have to be exactly the recommended values, but it IS critical that the actual

value of the signal connected to the controller be accurately known to at least four digits.

Calibration of Analog Inputs:

To calibrate an analog input, you will need to provide a source of two electrical signals or resistance values

near the extremes of the range that the application is likely to utilize. See recommended values below:

Sensor Type

Precision Source Low

Precision Source High

thermocouple

0.000 mV

50.000 mV

millivolts

0.000 mV

50.000 mV

volts

0.000V

10.000V

milliamps

0.000 mA

20.000 mA

100 Ω RTD

50.00 Ω

350.0 Ω

1,000 Ω RTD

500.0 Ω

3,500 Ω

thermistor 5 kΩ

50.00

5,000

thermistor 10 kΩ

150.0

10,000

thermistor 20 kΩ

1,800

20,000

thermistor 40 kΩ

1,700

40,000

potentiometer

0.000

1,200

Time

Temperature

Temperature Reading

from Sensor

Actual Process Temperature

Negative Calibration Offset will

compensate for the difference

between the Sensor Reading and

the Actual Temperature