Example 5: differential, Example 6: cascade, Differential – Watlow EZ-ZONE PM Integrated Controller User Manual

Page 153: Watlow ez-zone, Pm integrated controller, Chapter 10 applications, Process scale, Deviation scale

Watlow EZ-ZONE

®

PM Integrated Controller

•

150

•

Chapter 10 Applications

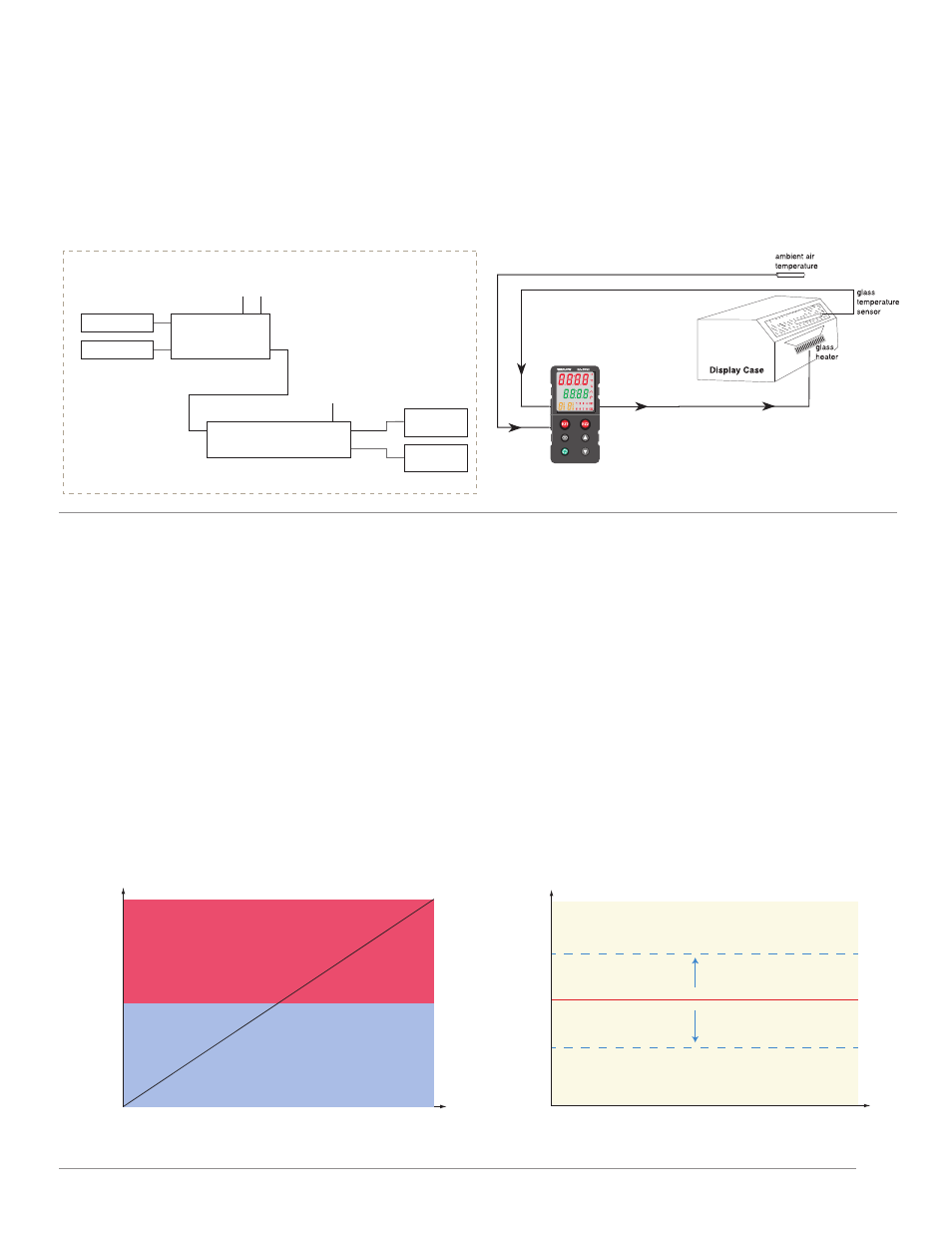

Example 5: Differential

Requirements:

Two analog inputs and the enhanced software option are required and at least one output adjusts the controlled

part of the process.

Overview:

Differential control maintains one process at a difference to another process. When function is set for Differential,

the PV Function output equals Source A minus Source B. Control loop 1 will control Analog Input 1 difference to

Analog Input 2 based on Closed Loop Set Point 1.

Example 6: Cascade

Requirements:

Two loops of control, two inputs and at least 1 output and the enhanced software option.

Overview:

Cascade control can handle a difficult process with minimal overshoot, while reaching the set point quickly. This

minimizes damage to system components and allows for over sizing heaters for optimal heat-up rates. Heater

life is also extended by reducing thermal cycling of the heater. Systems with long lag times between the energy

source (heater, steam, etc.) and the measured process value cannot be controlled accurately or efficiently with a

single control loop, because a lot of energy can build up before a response is detected. This can cause the system

to overshoot the set point, which could damage the heater, product or heat transfer medium, such as a heat trans-

fer fluid.

The majority of the user configuration is done via the Math function. There are two user selectable settings

that will enable Cascade control, Deviation Scale or process Scale. When Process Scale is selected the remote set

point will be within the defined Range low/high and Scale low/high settings. As an example, the graph below

shows a heat/cool application where the temperature range is between 32º to 1200º. With the scaling set as shown

100% cool will equate to 32º, likewise when the control is calling for 100% heat the temperature equates to 1200º.

When Deviation Scale is selected the Closed Loop Set Point (CLSP) will not deviate beyond the specified settings.

With the settings as shown in the graph below the CLSP (500º) will not deviate beyond ± 25º.

Heat/Cool

T

emperature

Process Scale

Scale Low

-100 %

Scale High

+100 %

Range Low

32o

Range High

+1200 o

0o

Cool

Heat

0 %

Heat/Cool

Deviation Scale

Scale Low

-100 %

Scale High

+100 %

-25

+25

0 %

CLSP = 500

Calculated inner loop (2) set point ± deviation

®

Input 1

Input 2

Output 1

Control Loop 1

Differential

Closed Loop

Set P

oint

1

Function

Filt

er

Source A

Source A

Source B

Heat Power

Cool Power

0 to 100%

0 to 100%

Output

Analog Input 1

Analog Input 2

Heat

Cool

Output n

Output n

PV Function