Example 9: motorized valve control, Motorized valve control – Watlow EZ-ZONE PM Integrated Controller User Manual

Page 156

Watlow EZ-ZONE

®

PM Integrated Controller

•

153

•

Chapter 10 Applications

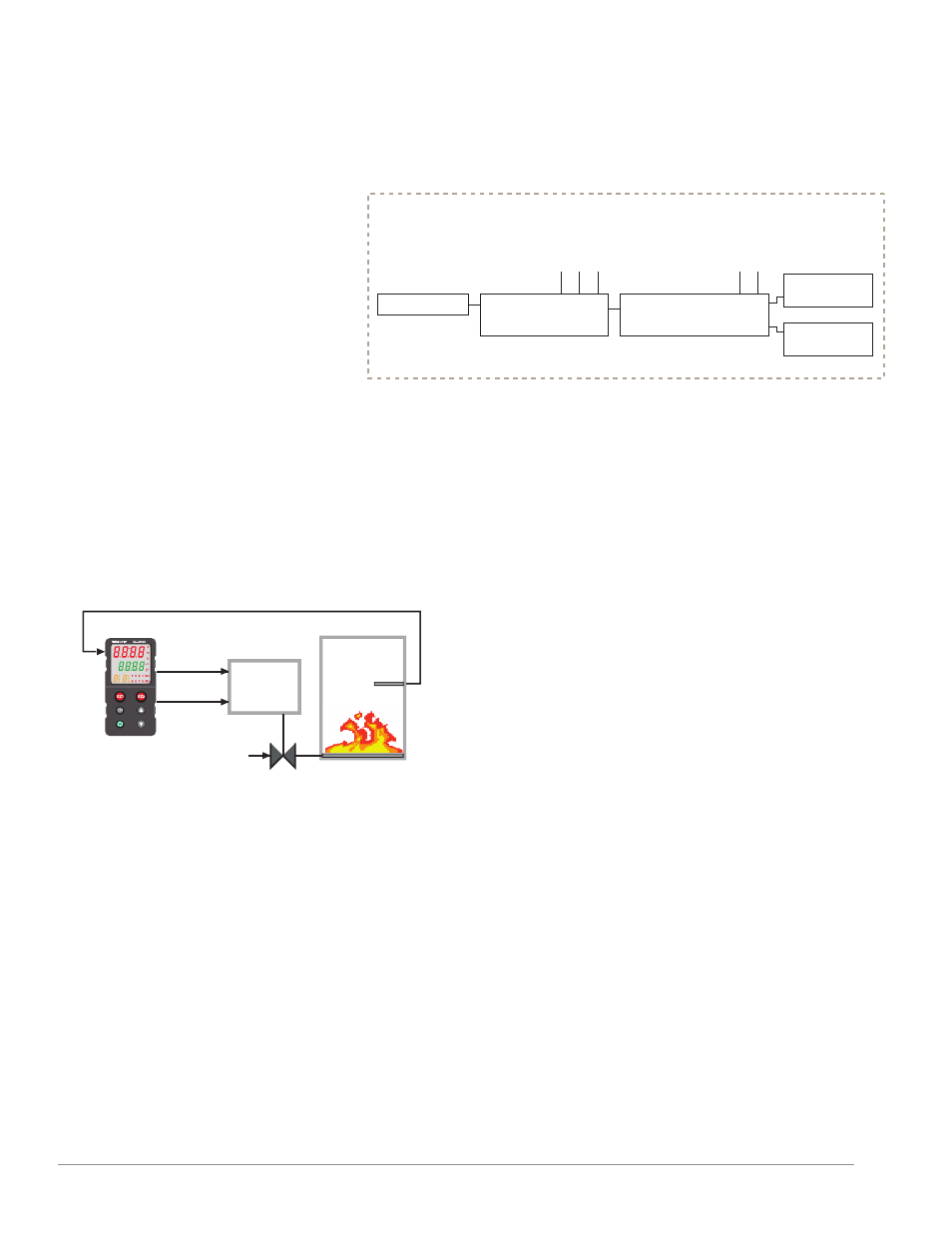

Example 9: Motorized Valve Control

A typical scenario where a motorized valve is used is to regulate the flow of fluid which in turn impacts the loop

process value. A valve is opened or closed by closing contacts to drive the value in the intended direction. Motor-

ized Valves come in a number of configurations. Some valves have a position feedback mechanism that allows the

control to measure the valve’s position via an internal potentiometer called slide-wire. The controller can measure

the potentiometer resistance to deter-

mine the initial valve position on power

up.

This method may not be desirable for

three reasons:

1) It requires a second input on the con-

troller to measure valve position.

2) The controller and the valve are more

expensive.

3) Additional wiring is required for the

slide-wire feedback.

Other valves take an analog signal and

have a localized control mechanism that regulates the valve position. These are typically more expensive valves

because of the control mechanism built-in plus it requires an analog signal which is not always available. The ac-

tual valve position is not critical because it is a part of a closed loop control.

The Motorized Valve control algorithm is also designed to work with a type of valve that provides two discrete sig-

nals: one to open the valve and another to close the valve. The algorithm turns on/off the appropriate signal for an

appropriate amount of time to approximate the valve position. This works when the valve is inside a closed control

loop because when the valve is not in the correct position, the PID algorithm will adjust the valve further open or

close as needed. These valves have travel limit switches which deactivates the motor once the valve is fully open

or fully closed so the controller can not cause the valve to over travel and burn out the motor, or the motor is built

so it can not overheat at max locked rotor amperes.

To use the motorized feature, the user programs the Special

Output Function to Motorized Valve. Then the Source Func-

tion A is selected to either Heat or Cool Power and Source In-

stance A is set to match the control loop, typically 1.

Next the user enters the amount of time in seconds that the

valve requires power to go from a closed state to an open

state. The user enters the dead band in percent PID power

to prevent the valve from excessive cycling. Larger numbers

reduce activity on the valve and smaller numbers improve

controllability. Select a value that compromises on these two

competing goals.

Lastly, assign an output to Special Output Function 1 that is wired to close the valve. Assign an output to Special

Output Function 2 that is wired to open the valve. Typically, these two outputs are normally open mechanical re-

lays but solid state relays or switch DC outputs may be programmed in the same manner.

Definitions:

- Current Position is an approximation of the valve's position as it relates to a power level (0 - 100%) where 0% is

fully closed and 100% is fully open.

- Dead Time is the minimum on time that the valve will travel once it is turned on in either the closed or open di-

rection. Dead Time = Valve Dead Band / 100 * Valve Travel Time.

- On Time is the amount of time the valve needs to be turned on (either open or close) to eliminate the error be-

tween the estimated valve position and the desired power level. A positive On Time value indicates the need to

open the valve while a negative value indicates the need to close the valve. On Time = (Input 1 Value - Current

Position) / 100 * Valve Travel Time

When power is applied to the controller, the valve is closed and time is set to 0.

- Special Output Function 1 is the close signal to the valve.

- Special Output Function 2 is the open signal to the valve

Output 1 = Close

Temperature

Sensor

Gas Furnace

Output 2 = Open

Gas Flow

Valve

Actuator

®

Control Loop 1

Closed Lo

op

Dead Band

Valve

Tra

vel Time

Set

Point

1

Heat

Algorithm

Cool

Algorithm

Analog Input 1

Source A

Close

Open

Output n

Output n

Heat Power

Source Function A

Special Output Function 1

Special Function

Output 1

Special Function

Output 2

Motorized Valve Control