Single set point ramping, Cascade control, Compressor control – Watlow EZ-ZONE PM Integrated Controller User Manual

Page 138: Variable time base ( cont . )

Watlow EZ-ZONE

®

PM Integrated Controller

•

135

•

Chapter 9 Features

Variable Time Base (cont .)

Variable time base should be used with solid-state power controllers, such as a solid-state relay (SSR) or

silicon controlled rectifier (SCR) power controller. Do not use a variable time base output for controlling elec-

tromechanical relays, mercury displacement relays, inductive loads or heaters with unusual resistance char-

acteristics.

The combination of variable time base output and a solid-state relay can inexpensively approach the effect

of analog, phase-angle fired control.

Select the AC Line Frequency [AC;LF] (Setup Page, Global Menu), 50 or 60 Hz.

Note:

When output 1 is a universal process output, output 2 cannot use variable time base, fixed time base only.

When output 3 is configured as a universal process, output 4 cannot use variable time base, fixed time base

only.

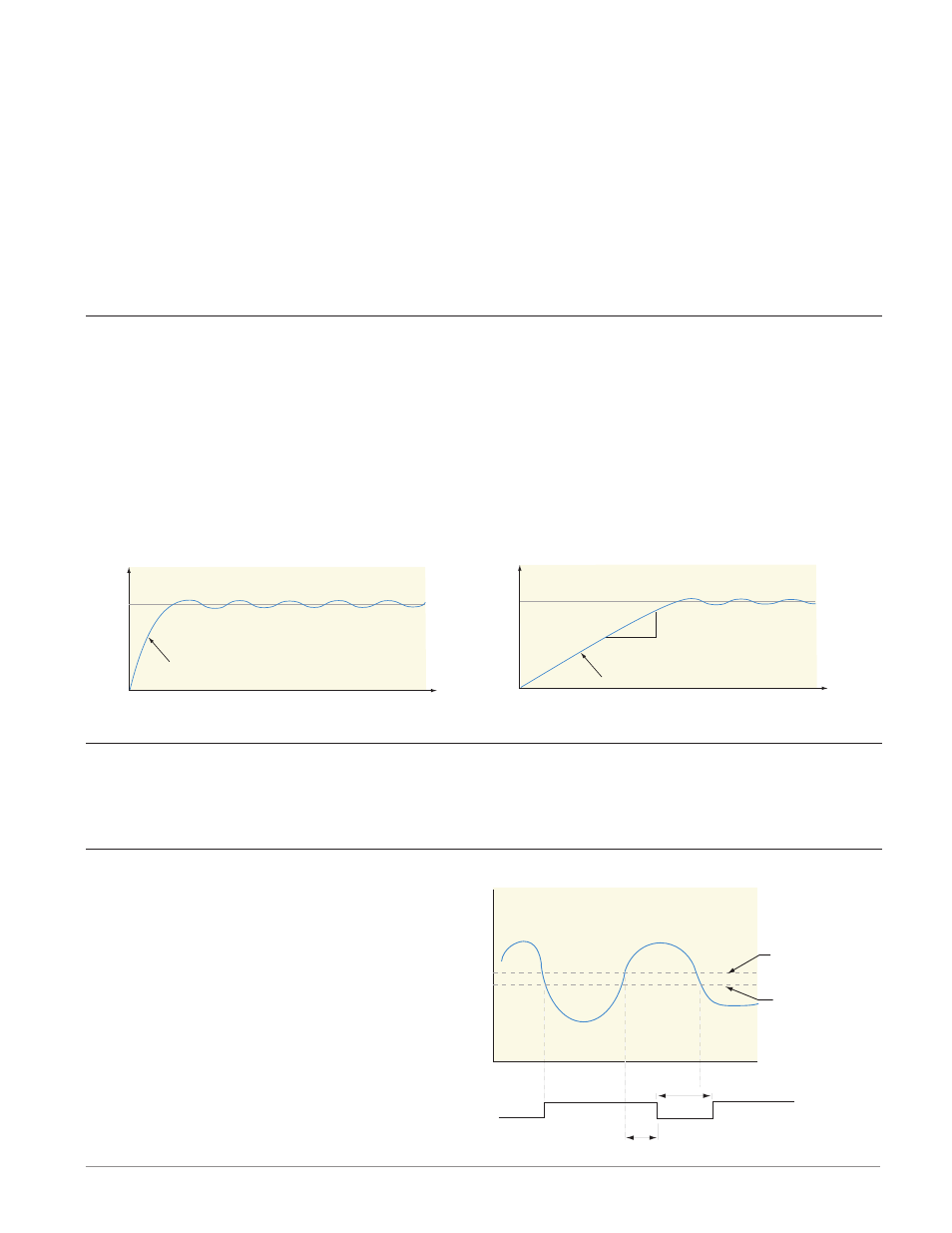

Single Set Point Ramping

Ramping protects materials and systems that cannot tolerate rapid temperature changes. The value of the

ramp rate is the maximum degrees per minute or hour that the system temperature can change.

Select Ramp Action [``rP] (Setup Page, Loop Menu):

[`oFF]

ramping not active.

[`Str]

ramp at startup.

[StPt]

ramp at a set point change.

[both]

ramp at startup or when the set point changes.

Select whether the rate is in degrees per minute or degrees per hour with Ramp Scale [`r;SC]. Set the ramp-

ing rate with Ramp Rate [`r;rt] (Setup Page, Loop Menu).

Cascade Control

The PM (PM4/8/9) can be configured for Cascade control with enhanced firmware. Cascade is used to opti-

mize the performance of thermal systems with long lag times. It utilizes a control strategy in which one con-

trol loop provides the set point for another loop. See

Compressor Control

The PM control can be configured for Com-

pressor control with enhanced firmware.

The compressor control can save wear on a

compressor and prevent it from locking up

from short cycling. A bypass valve operated

by a control output regulates how the pro-

cess is cooled, while another output switches

the compressor on and off. The compres-

sor will not turn on until the output power

exceeds the Power On Level % for a time

longer than the specified On Time. The com-

pressor will not turn off until the output

power is equal to or less than the Power Off

Level % for a time longer than the specified

Off Time.

Set Point

Time

Temperature

Heating System without Ramping

Temperature reaches Set Point quickly

Set Point

Time

Temperature

Temperature ramps to Set Point at a set rate

degrees

per minute

Heating System with Ramping

0% Compressor

On Power

Off

On

100%

2%

0%

-100%

Compressor On Delay = 45 Seconds

Compressor Off Delay = 20 Seconds

2% Compressor

Off Power

Time In Seconds

% Power

Heat

Cool

Compressor