IAI America XSEL-KET User Manual

Page 394

375

INTELLIGENT ACTUATOR

Speed-loop integral time constant

Driver card parameter number

Unit

Input range

Default value (reference)

39

-

0 to 1000

30

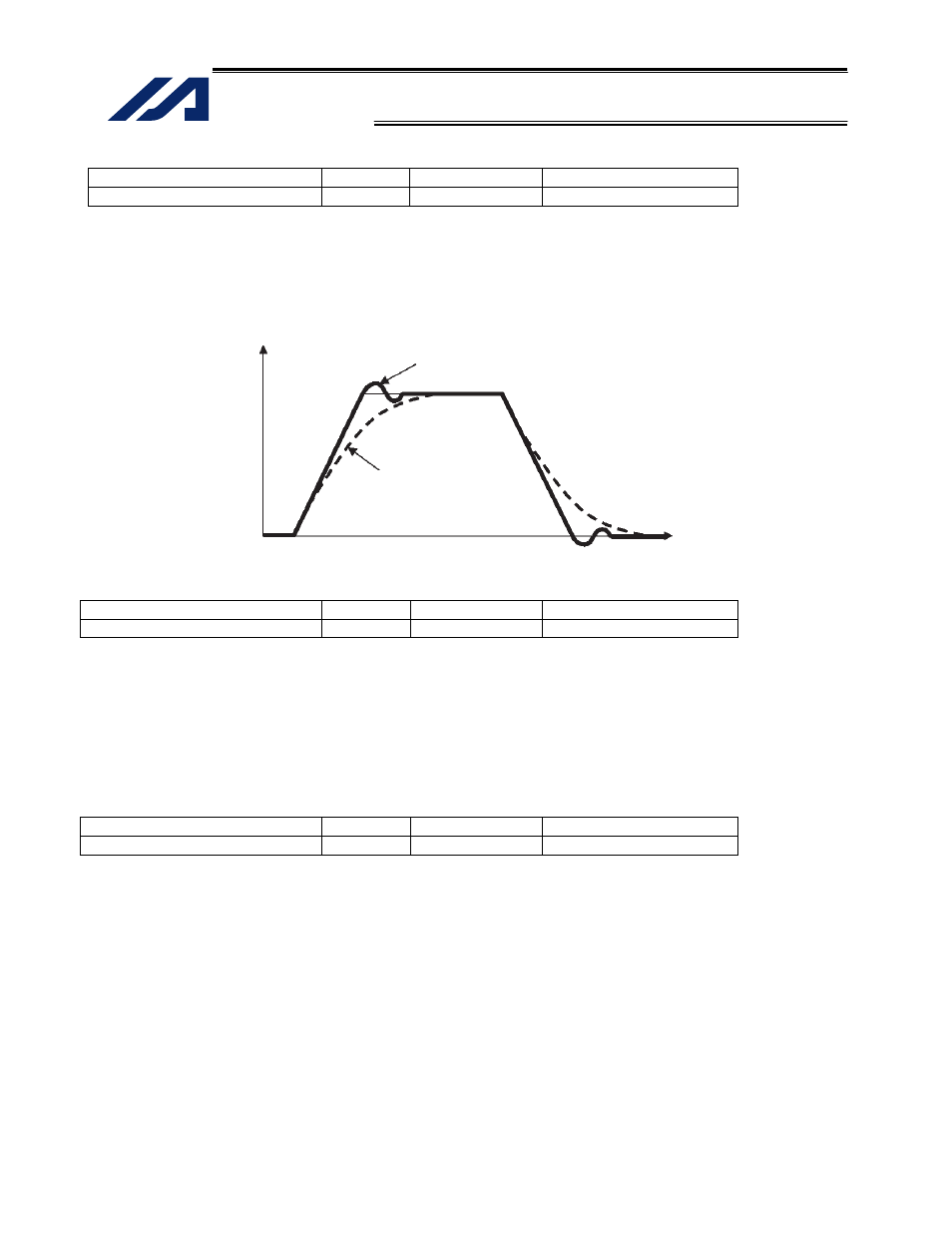

This parameter determines the response of the speed control loop.

Increasing the set value lowers the response to the speed command and reduces the reactive force to load

change. Also, conformance to the position command drops and positioning takes a longer time.

An excessively low setting may trigger overshooting or oscillation and cause the mechanical parts to vibrate

easily.

Current-loop control band number

Driver card parameter number

Unit

Input range

Default value (reference)

40

-

0 to 4

4

This parameter sets the control band for the PI current control system.

Normally the default setting need not be changed.

If this parameter is changed carelessly, safety of the control system may be compromised and a very dangerous

situation may occur.

If the actuator generates resonance noise, etc., however, changing this parameter will help reduce the

resonance noise.

Consult IAI if you wish to change this parameter.

Torque filter time constant (Parameter list 1)

Driver card parameter number

Unit

Input range

Default value (reference)

42

-

0 to 2500

0

This parameter determines the filter time constant for the torque command.

The motor will vibrate if the resonance frequency of the machine is equal to or below the response frequency of

the servo loop.

This mechanical resonance can be reduced by increasing the value set in this parameter.

However, safety of the control system may be compromised if the setting is increased excessively.

Speed

Set value is low (overshoot).

Set value is high.

Time