Pcon-ca/cfa, Power con – IAI America PCON-CA User Manual

Page 211

Chapter 8

Troubleshooting

POWER CON

PCON-CA/CFA

203

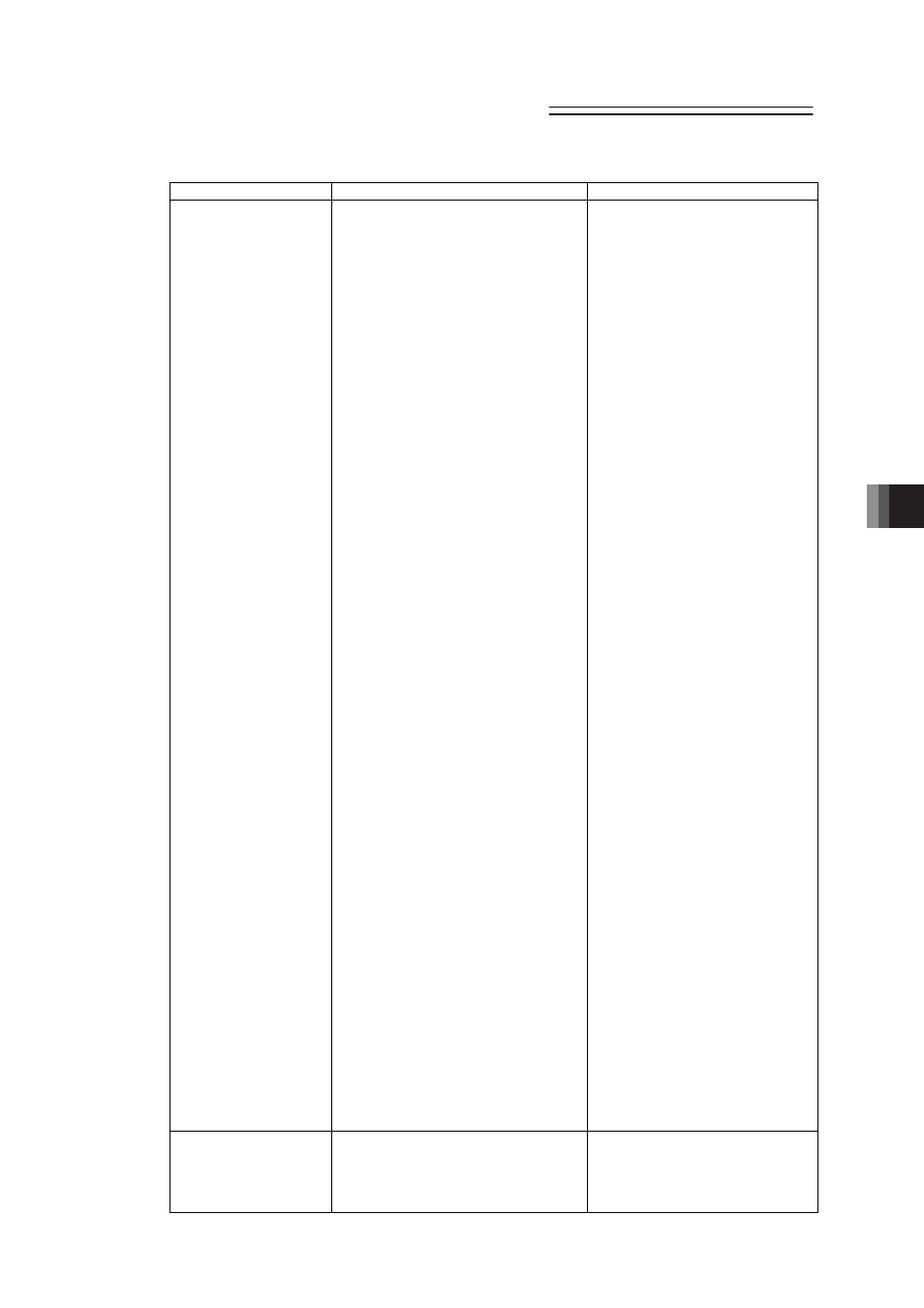

[In the case of Pulse Train Control Mode]

Situation

Possible cause

Check/Treatment

The actuator does not

stop at the command

position.

PIO signal processing or parameter

setting is incorrect.

1) Incorrect electronic gear ratio

2) Acceleration/deceleration is set

incorrectly in the host controller.

3) Noise

4) The pulse-train type, a parameter, is

selected incorrectly.

5) The unit moving distance per pulse,

which is a setting condition of

electronic gear ratio, a parameter, is

too small.

1) Check the setting of electronic

gear ratio. The host controller

also has the electronic gear ratio

parameter. Set the electronic

gear ratio not to be inconsistent

with that of the host controller. In

addition, reduce the electronic

gear ratio as much as possible.

If not, data overflow may occur

in arithmetic processing to

disable correct positioning.

[Refer to 3.3.4 [1] Electrical

Gear Setting.]

2) The actuator operates at the

speed and

acceleration/deceleration based

on the frequency of input pulses.

Check if the

acceleration/deceleration set in

the host controller exceed the

rating acceleration/deceleration

of the actuator.

3) Noise can be misread as the

pulse if it jumps into the pulse

train.

Take proper measures against

noise. [Refer to 1.7 Noise

Elimination and Mounting

Method.]

Check the cable connection

between the controller and

AK-04 if AK-04 is used.

• Cable length :

50mm or shorter

recommended (as short as

possible)

• Shield treatment :

Use the shield treatment wire.

4) Check the pulse-train type.

[Refer to 3.3.4 [2] Format

Settings of Command Pulse

Train.]

5) Do not make the unit moving

distance less than the resolution

of the encoder. The actuator

does not move unless pulses by

the resolution of the encoder are

input.

[Refer to Caution in 3.3.4 [1]

Electrical Gear Setting]

(Note) In case of 2) or 3), the

actuator may not

sometimes operate.

You may not find case 4)

when the actuator is

moved for a long

distance at a high

frequency.

The actuator does not

reach the command

position when operated

with extremely low

speed.

To avoid unnatural move, the actuator

would not move unless the differential

pulse becomes 3 pulses or more.

Set to the full-servo mode. (Set

Parameter No.53 Stop Mode initial

setting to 4.)