2 fault diagnosis, Pcon-ca/cfa, Power con – IAI America PCON-CA User Manual

Page 206: 1 impossible operation of controller

Chapter 8

Troubleshooting

POWER CON

PCON-CA/CFA

198

8.2

Fault Diagnosis

This section describes faults largely divided into three types as follows:

(1) Impossible operation of controller

(2) Positioning and speed of poor precision (incorrect operation)

(3) Generation of noise and/or vibration

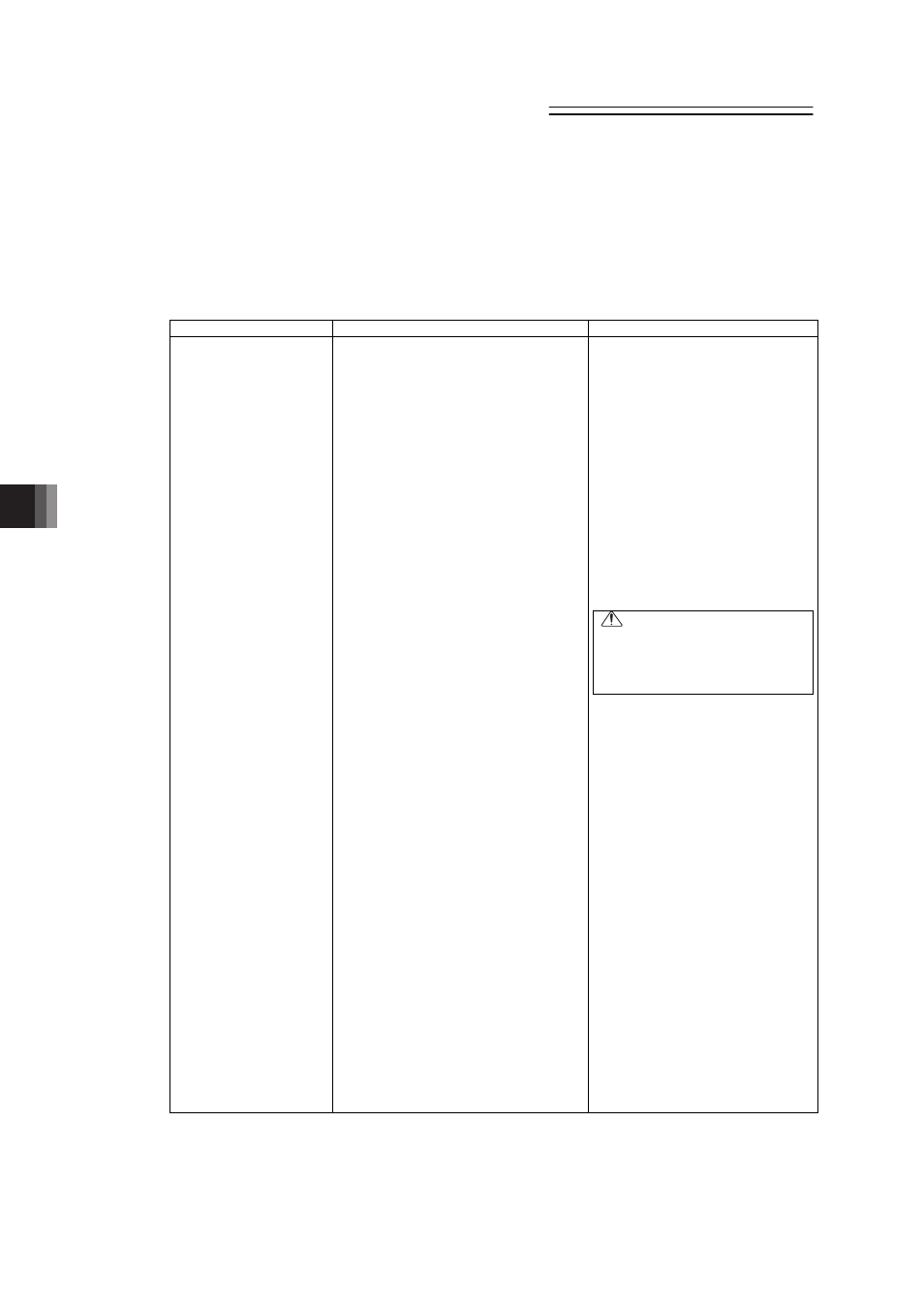

8.2.1 Impossible operation of controller

Situation

Possible cause

Check/Treatment

At power-on, SV on the

status indicator LEDs

does not go ON.

(1) Proper power is not supplied.

(2) Servo-on command (PIO) is not

input to IAI controller.

1) 24V DC power for PIO is not

supplied.

2) Poor contact of flat cable

3) The operation mode setting

switch on the front panel is on

“MANU” side.

4) The +/- pins of 24V DC power for

PIO are connected inversely.

(3) Occurrence of alarm.

(4) During emergency-stop.

1) Was the emergency-stop switch.

2) EMG- on the power supply

connector is not connected.

(1) Ensure that appropriate voltage

is supplied and the wiring is in

the right condition.

[Refer to 2.3.1 Wiring Layout of

Power Supply Connector.]

(2) 1) Check the PIO power

voltage. When a large load is

applied to one power source,

there is a risk of power

voltage drop or a shutdown of

the output.

2) Are the PIO cable connectors

inserted to the mating

connectors securely? Check

the input signals on the I/O

monitor of the teaching tool

such as PC software.

Caution

In I/O cable conduction check,

do not widen female pins of the

connectors. Failure to follow this

may cause poor contact.

3) Can such operation as

jogging be performed from

the teaching tool such as PC

software? Set the operation

mode setting switch on the

front panel and restart the

controller.

[Refer to Name for Each

Parts and Their Functions.]

4) Ensure there is no problem in

the input and output on the

host controller (PLC) side

when the reversed

connection of PIO power

source is conducted.

(3) Check the error code with the

teaching tool being connected

and remove the cause by

referring the alarm list.

[Refer to 8.4 Alarm List.]

(4) 1) Release the emergency stop

switch.

2) Check the connection of the

power connector (EMG-).

[Refer to 2.3.1 Wiring Layout

of Power Supply Connector.]