Pcon-ca/cfa, Power con – IAI America PCON-CA User Manual

Page 203

Chapter 7 I/O Parameter

POWER CON

PCON-CA/CFA

195

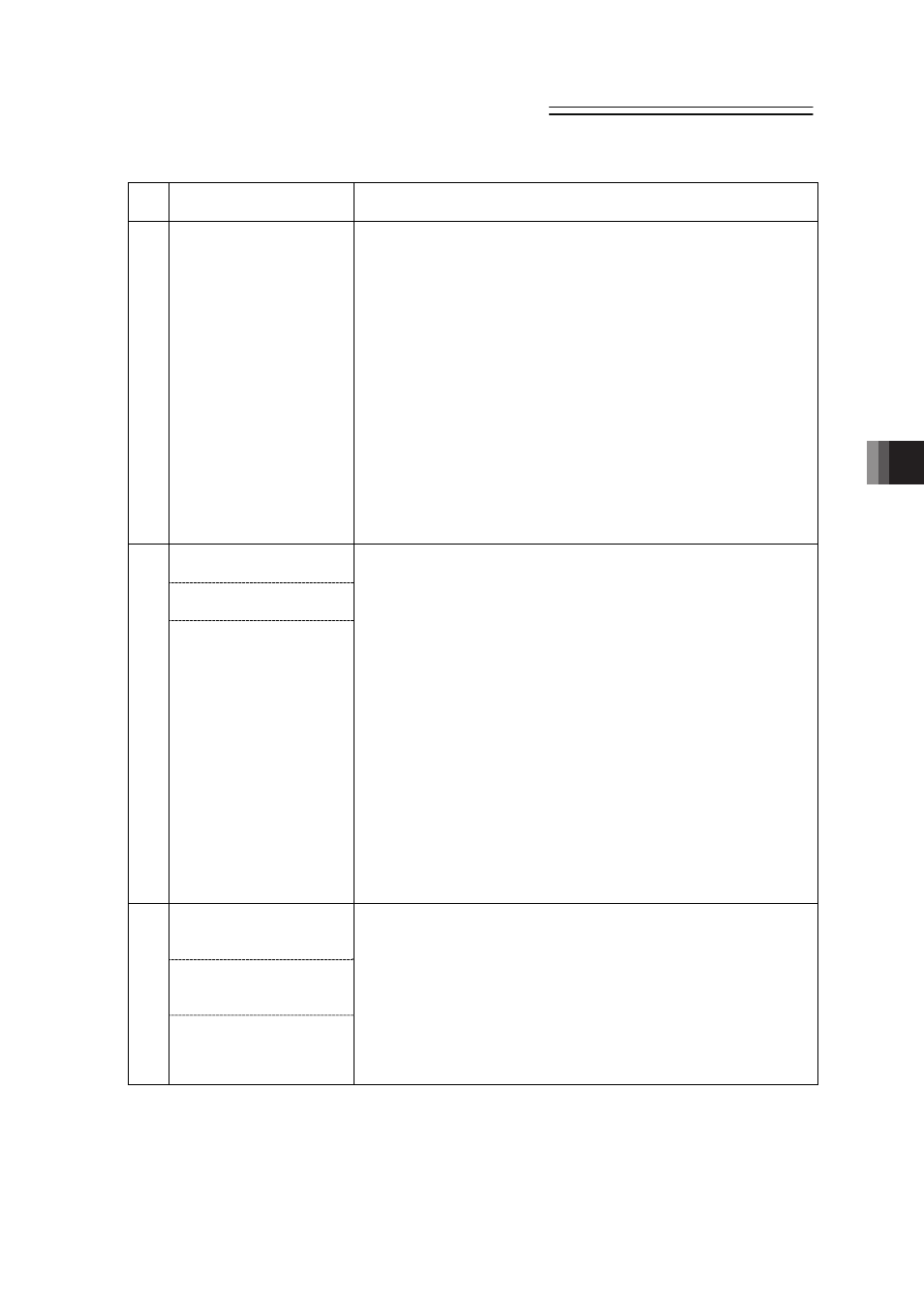

No.

Situation that requires

adjustment

How to Adjust

4 Abnormal noise is

generated.

Especially, when stopped

state and operation in low

speed (less than

50mm/sec),

comparatively high noise

is generated.

Ɣ Input the “Torque Filter Time Constant”. Try to increase by 50 as

a reference for the setting. If the setting is too large, it may cause

a loss of control system stability and lead the generation of

vibration.

[Important] Prior to Adjustment:

This phenomenon is likely to occur when the stiffness of the

mechanical components is not sufficient. The actuator itself may

also resonate if its stroke is over 600mm or it is belt-driven type.

Before having an adjustment, check if:

1) The value for “parameter No.7 “Servo gain number””,

“parameter No.31

(Note 1)

“Velocity loop proportional gain””, or

“parameter No.32

(Note 1)

“Velocity loop integral gain”” are

excessive.

2) The stiffness of the load is sufficient as much as possible, or the

attachments are not loosened.

3) The actuator unit is mounted securely with a proper torque.

4) There is no waviness on the actuator mounting surface.

Trace precision is desired

to be improved.

Equi-speed performance

is desired to be improved.

5

Response is desired to

be improved.

Ɣ Make the condition optimized with Parameter No.7 “Servo gain

number” and Parameter No.31

(Note 1)

“Velocity loop proportional

gain” adjusted by referring to the way to adjust stated in No. 1 to

3 in the previous page.

[Reference]

The most important factor is to select the actuator (motor).

The servo is extremely sensitive to the inertia of the load. If the

inertia moment of the load is too large in comparison with the

inertia moment of the servo motor itself, the motor is highly

affected by the load. This may cause the actuator to be

controlled unstably.

Therefore, to improve the precisions of the trace, position, speed

and response of the actuator, the load inertia ratio must be made

small.

For high trace precision, equi-speed performance, and response

of the actuator in such a use as application, it is better to use ball

screws with small leads in the actuator as much as possible and

an actuator of motor capacity higher by at least one level.

The best method is to calculate the load inertia to select the

proper actuator.

Large static friction of

load makes actuator start

slowly.

Large load inertia makes

response of actuator low

at start and stop.

6

Takt time is desired to be

shortened.

Ɣ Set parameter No.71 “Feed forward gain”.

Select a value in the range from 10 to 50 roughly. The larger the

setting value is, the smaller the deviation is. Then the response

is improved.

Setting a large value may cause vibrations and/or noises to

occur.

Set the feed forward gain in order to improve the response of the

actuator further after adjusting Parameter No.7 “Servo gain

number” and Parameter No.31

(Note 1)

“Velocity loop proportional

gain”.

Note 1 For the actuators (RCP4) available for high output, set four sets of Velocity Loop

Proportional Gain and select a parameter to use. [Refer to Item [88] in 7.2 Detail

Explanation of Parameters for the details.]