Cub Cadet 6 x 4 Big Country User Manual

Page 98

Section 6: Front Suspension

6 - 3

6

2.7.

Pronounced tread wear at the inner edge of

either front tire indicates a negative camber con-

dition (leaning in at the top) at that wheel.

NOTE: If the Big Country is consistently oper-

ated with a heavy load, this may be normal wear

for the conditions.

NOTE: Mechanical causes of negative camber

include: weak or broken front springs, bent

steering knuckle, bent axle assembly, bent

spring mount.

NOTE: Worn wheel bearings or wear in the joint

where the steering knuckle meets the axle

assembly may cause apparent negative camber,

but the worn items must be repaired before cam-

ber evaluation is made.

2.8.

Pronounced tread wear at the outer edge of

either front tire indicates a positive camber con-

dition (leaning out at the top) at that wheel.

NOTE: Mechanical causes of positive camber

Include: bent steering knuckle, bent axle assem-

bly.

2.9.

Feathered edges on the tread blocks indicate a

toe angle issue. Proper alignment will correct

this condition.

NOTE: If the tread blocks appear smeared

(feathered) toward the outside edge of the tire, it

has toe-in (the front of the tires is closer together

than the back of the tires).

NOTE: If the tread blocks appear smeared

(feathered) toward the inside edge of the tire, it

has toe-out (the front of the tires is farther away

from each other than the back of the tires).

2.10. Scalloped tread indicates some form of oscilla-

tion while the tire is rotating. Mechanical sources

of this sort of problem would include: bent

wheels, a worn tie rod end, worn wheel bear-

ings, failed shock and spring unit, worn joint

between the steering knuckle and the axle

assembly, worn steering rack, bad tire.

2.11. Check the condition of the rubber bump stops

2.12. Place a block next to each front tire for sighting

purposes, and spin each tire. They should both

spin true to within 1/4” measured at the sidewall.

The bearings should spin quietly.

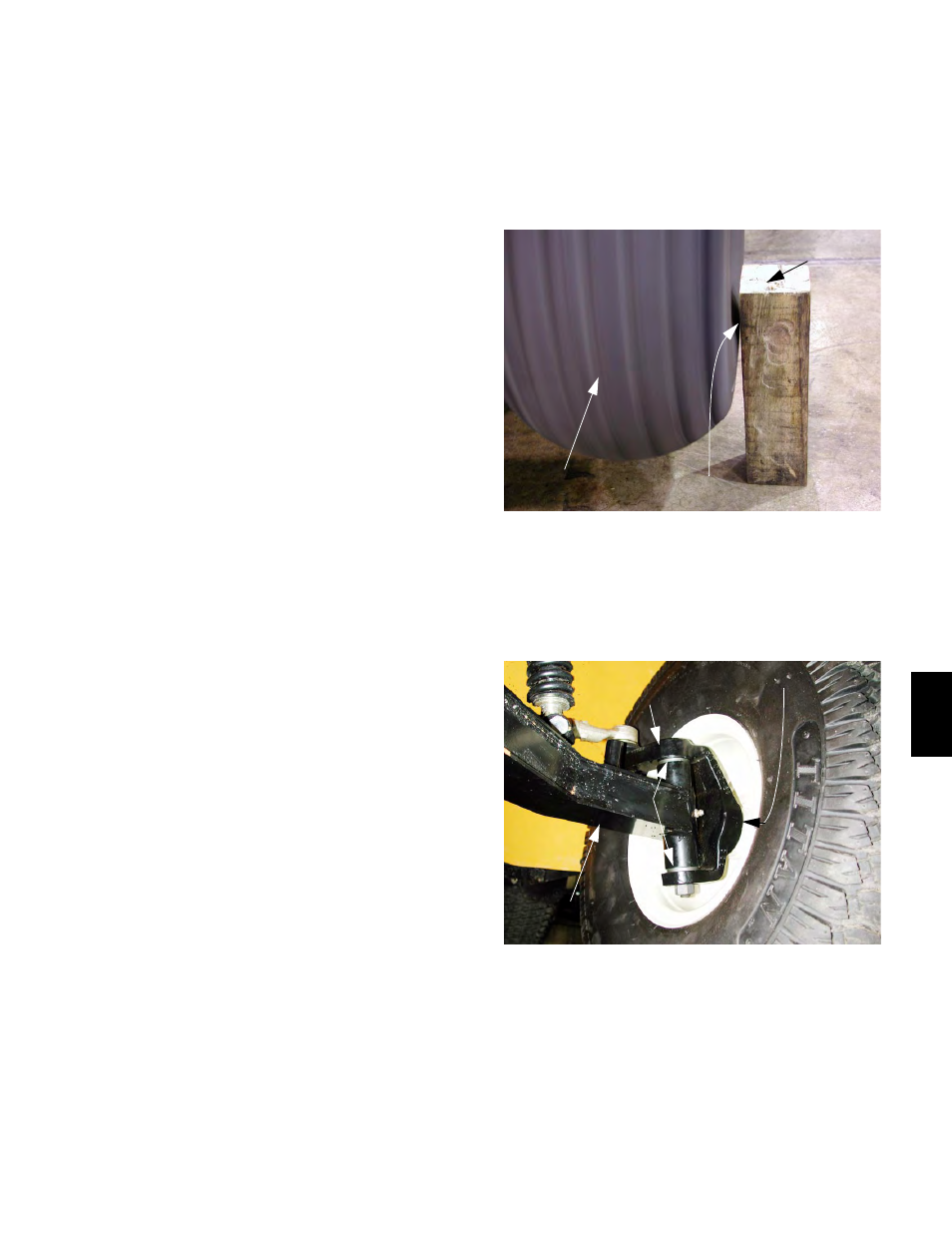

See Figure 2.12.

2.13. Grip the top and bottom of each front tire, and

attempt to rock it in a vertical plane. If more than

1/8” of play is present, identify the source of the

play. See Figure 2.13.

NOTE: The two greatest potential sources of

play are worn wheel bearings and worn compo-

nents at the joint between the steering knuckle

and the axle assembly (sleeve bushings, pivot

bolt, spacer).

Figure 2.12

Sighting Block

Spinning Tire

Watch Gap Here

Figure 2.13

Wheel Bearing Play Here

Axle Assembly

Steering Knuckle

Look For Play Here