Axle and bearing removal and replacement – Cub Cadet 6 x 4 Big Country User Manual

Page 68

Section 3: Drive Axle Service

3 - 25

3

16.

Axle and Bearing Removal and Replacement

16.1. Remove the axle assembly as described in the

“Drive Axle Service: Front Drive Axle Removal

and Replacement” or “Rear Suspension Service:

Rear Drive Axle Removal and Replacement”

section of this manual.

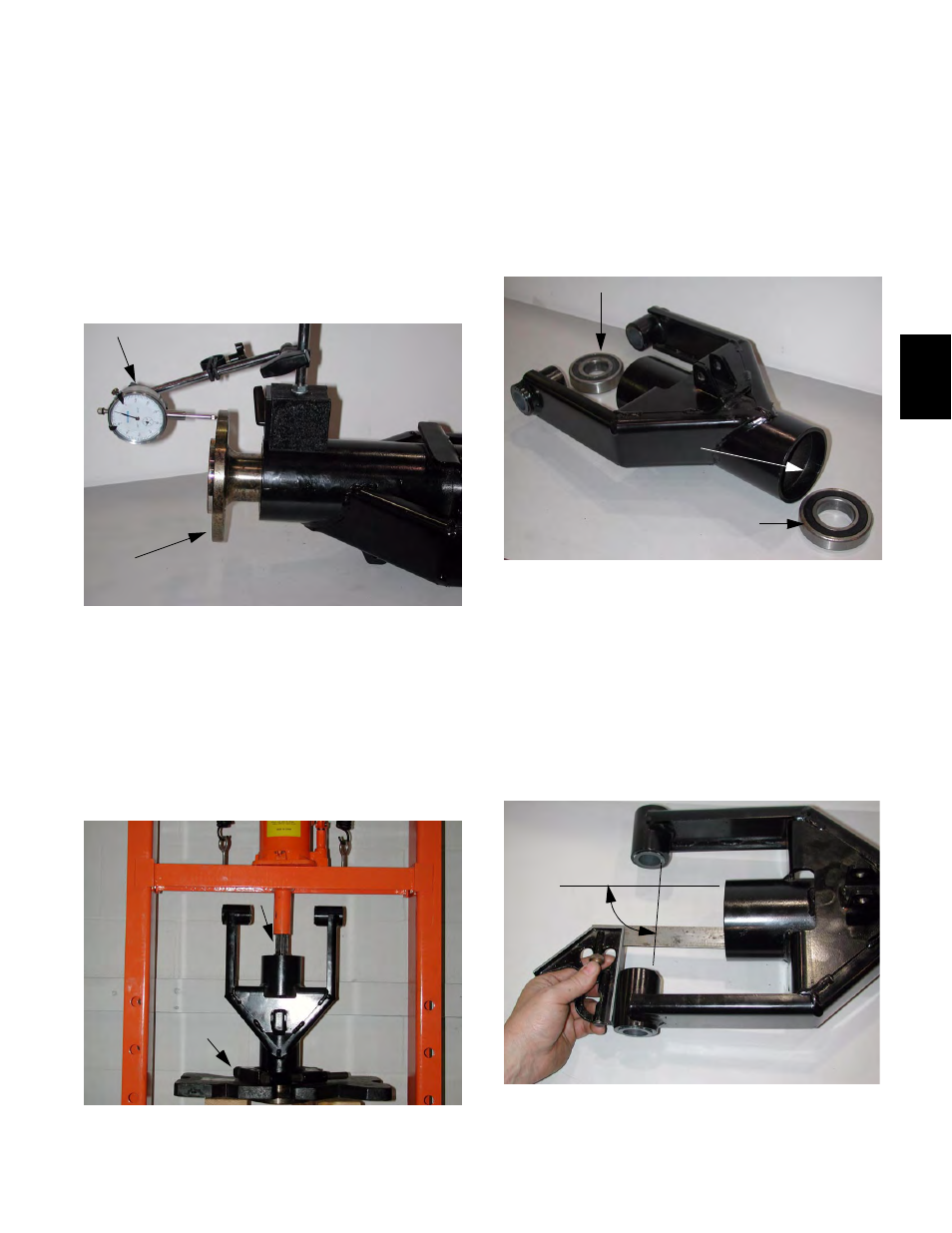

16.2. If there has been collision damage to the Big

Country, check the axle flange for run-out. See

Figure 16.2.

NOTE: Run-out check may be done with the

axle mounted in the Big Country, or on the

bench.

16.3. To Disassemble the axle, safely position the

axle assembly in a press. Support the outer axle

bearing and press the axle shaft out of the bear-

ings. See Figure 16.3.

Figure 16.2

Dial Indicator

Axle Flange

Figure 16.3

Press Axle

Support

Outer Axle

Bearing

16.4. Drive the inner axle bearing out of the axle

assembly using a hammer and soft drift. When

driving the bearing, apply force to the outer race.

16.5. Drive the outer axle bearing out of the axle

assembly using a hammer and soft drift. When

driving the bearing, apply force to the outer race.

See Figure 16.5.

16.6. Inspect the bearings for damage, looseness,

and smooth rotation.

16.7. Inspect the axle shaft. Pay particular attention to

the condition of the splines.

16.8. Inspect the axle weldment for collision damage

and trueness. The axle bushings should be at a

90 degree angle to the tube that the axle bear-

ings fit in. See Figure 16.8.

Figure 16.5

Outer Axle Bearing (Larger I.D.)

Inner Axle Bearing (Smaller I.D.)

Machined Shoulder

Figure 16.8

90 deg.