Cub Cadet 6 x 4 Big Country User Manual

Page 38

Section 2: Clutch, Transmission, Brakes, Linkages

2- 29

2

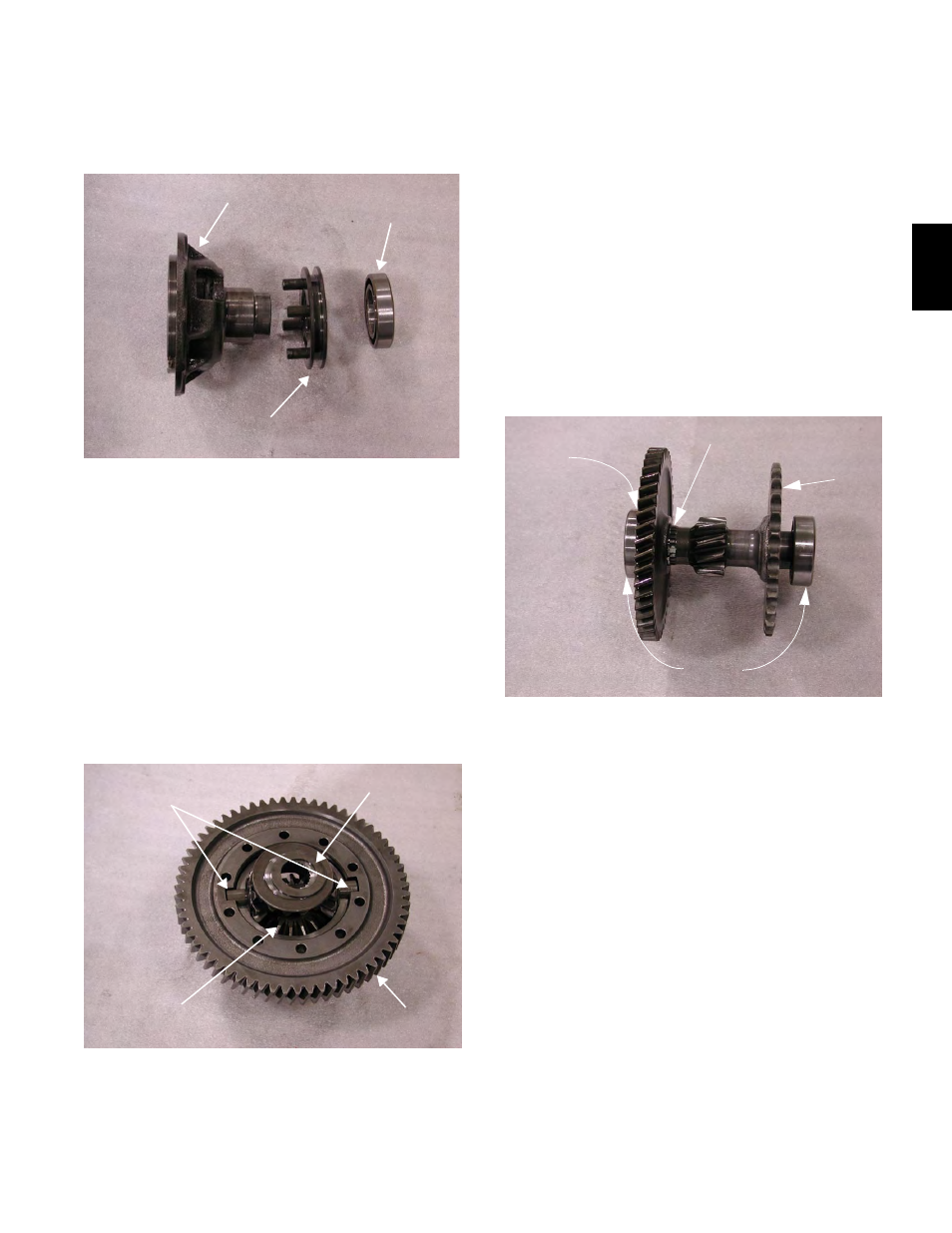

18.32.Check the pins on the differential lock slider.

NOTE: Bent or damaged pins on the differential

lock slider indicate that the differential lock is

likely to have been engaged at speed. The

Operator’s Manual specifies that the Big Country

be stopped when the differential lock engage-

ment lever is pulled-up by the operator. Damage

to the differential lock slider pins generally con-

stitutes abuse.

18.33.Lubricate all contact points with assembly lube

or universal (hydraulic) tractor transmission fluid

and put the differential together.

See Figure 18.33.

Figure 18.32

Differential Housing

Differential Lock Slider

Differential

Bearing

Figure 18.33

Side Gear

Thrust

Washer

Side Gear

Final

Gear

Flat Indexes

To Final

Gear

NOTE: Make certain side gear thrust washer is

centered before tightening the fasteners that

hold the differential housings and final gear

together.

18.34.Apply thread locking compound such as Loctite

242 to the bolts that hold the differential hous-

ings and final gear together.

18.35.Tighten the nuts on the bolts, and torque the

nuts to 225 to 260 in-lbs. in two steps using two

12mm wrenches.

18.36.Clean and inspect the reduction shaft assembly.

NOTE: Check the profile of the teeth on the

sprocket, particularly if the chain is to be

replaced. If worn, the sprocket and shaft must be

replaced.

NOTE: Check the bearings for tightness and

smoothness of rotation. Use an appropriate

puller to remove the bearings if necessary. The

bearing nearest the gear is held on by a snap

ring.

NOTE: check the gear teeth and splines for

abnormal wear.

Figure 18.36

Bearings

Sprocket

Splines

Snap Ring