Bio-Rad BioLogic Signal Import Module (SIM) User Manual

Page 212

TROUBLESHOOTING

MAINTENANCE AND TROUBLESHOOTING

12-5

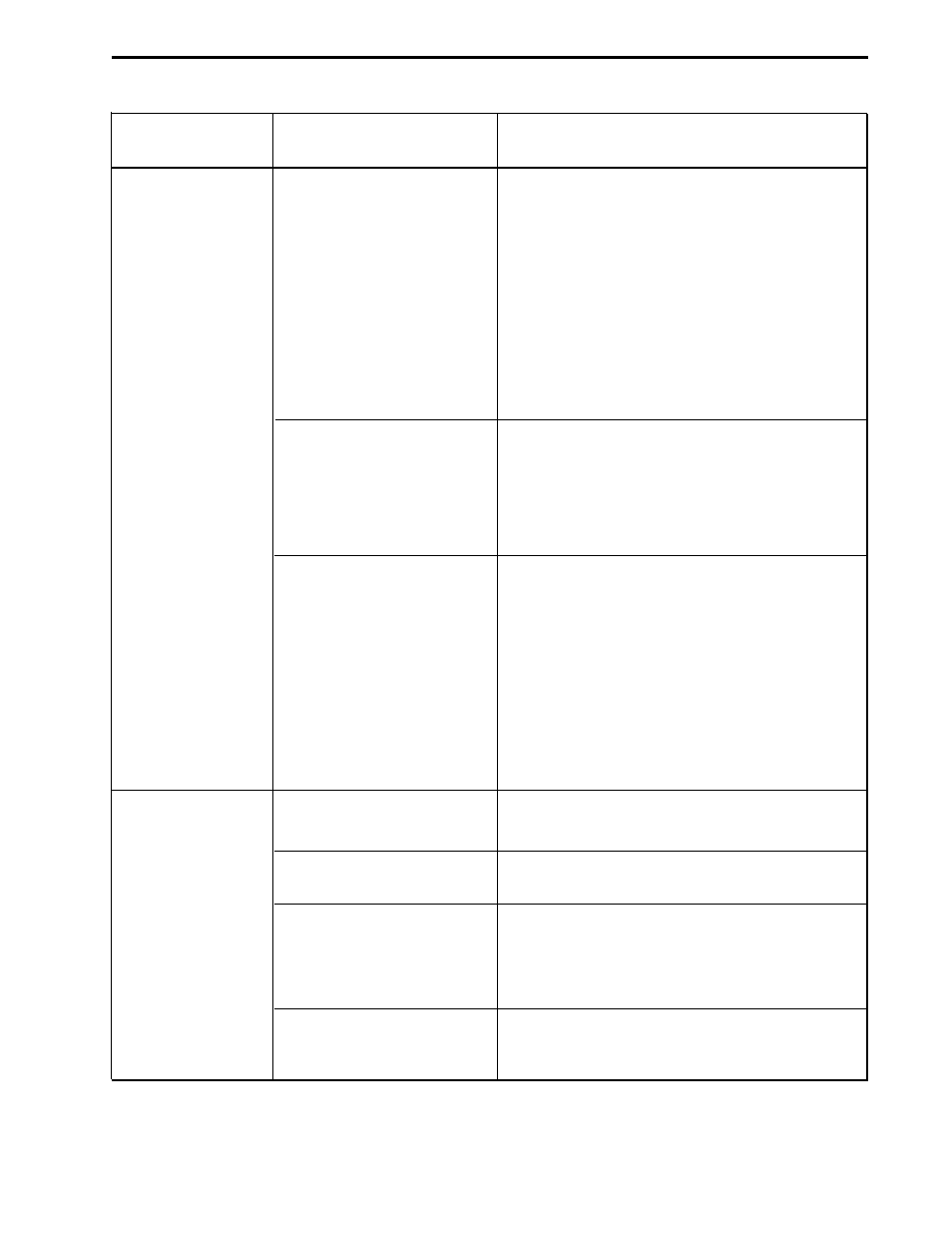

Problem

Possible Cause

Solution

Delivery of liquid is

Severe fluctuation in the back-

erratic and the

pressure readout indicates an

pressure readout

air bubble trapped in one or

on the Controller

both of the pumpheads.

status bar is

fluctuating more

Note: Always degas buffers

than 20%.

before use.

The pump’s check valves may

need cleaning or replacement.

The backpressure

Flow rate may have

displayed on the

been changed.

Controller status

bar drops to zero

There may be a tubing

or is much lower

or fitting leak.

than expected.

Pump seals may

need replacement.

Check valves may need

cleaning or replacement.

1. Put the AVR7-3 valve into the purge position

and purge the system by pressing the Purge

buttons on the front panel of the Workstation.

2. Stop or Pause the pumps and re-prime. Loosen

the top fitting on the pumphead and force any

trapped air out of the pumphead by squirting

buffer through the priming port using a syringe.

Refer to the maintenance section on how to

prime the Workstation pump and remove

trapped air bubbles. Always use degassed

buffers.

3. To minimize this problem, use degassed buffers

and solutions. Degas buffers by stirring

vigorously under vacuum for approximately 20

minutes. Use a heavy-wall side-arm Erlenmeyer

flask, as standard flasks may implode under

vacuum.

4. Clean (or replace) the check valves (see

section 11.3.3, Routine Maintenance of the

Workstation Pump.)

a. Cleaning: Sonicate check valves in a warm

detergent solution, rinse with deionizied (DI)

water, and re-install.

Replacing: Replace badly clogged or

damaged check valves.

b. Recalibrate the pumps after

cleaning/replacing check valves. Select

Gradient Pump Calibration from the

Utilities drop-down menu.

1. Confirm that the flow rate setting has not been

changed.

2. Re-inspect all tubing connections, especially at

the pump inlet.

3. Replace pump seals. A build-up of crystallized

buffer salts on the rear of the pumphead is a

clear sign for seal replacement. (see Section

11.3.3, Routine Maintenance of the Workstation

Pumps.)

4. Clean or replace check valves. (see Section

11.3.3, Routine Maintenance of the Workstation

Pumps.)

- BioLogic DuoFlow Pathfinder 80 System DuoFlow™ Chromatography System BioLogic DuoFlow Pathfinder 20 System DuoFlow™ Chromatography System BioLogic DuoFlow Maximizer 80 System DuoFlow™ Chromatography System BioLogic DuoFlow Maximizer 20 System DuoFlow™ Chromatography System BioLogic DuoFlow QuadTec 40 System DuoFlow™ Chromatography System BioLogic DuoFlow QuadTec 10 System DuoFlow™ Chromatography System BioLogic DuoFlow 40 System Chromatography System BioLogic DuoFlow 10 System Chromatography System