Bio-Rad BioLogic Signal Import Module (SIM) User Manual

Page 211

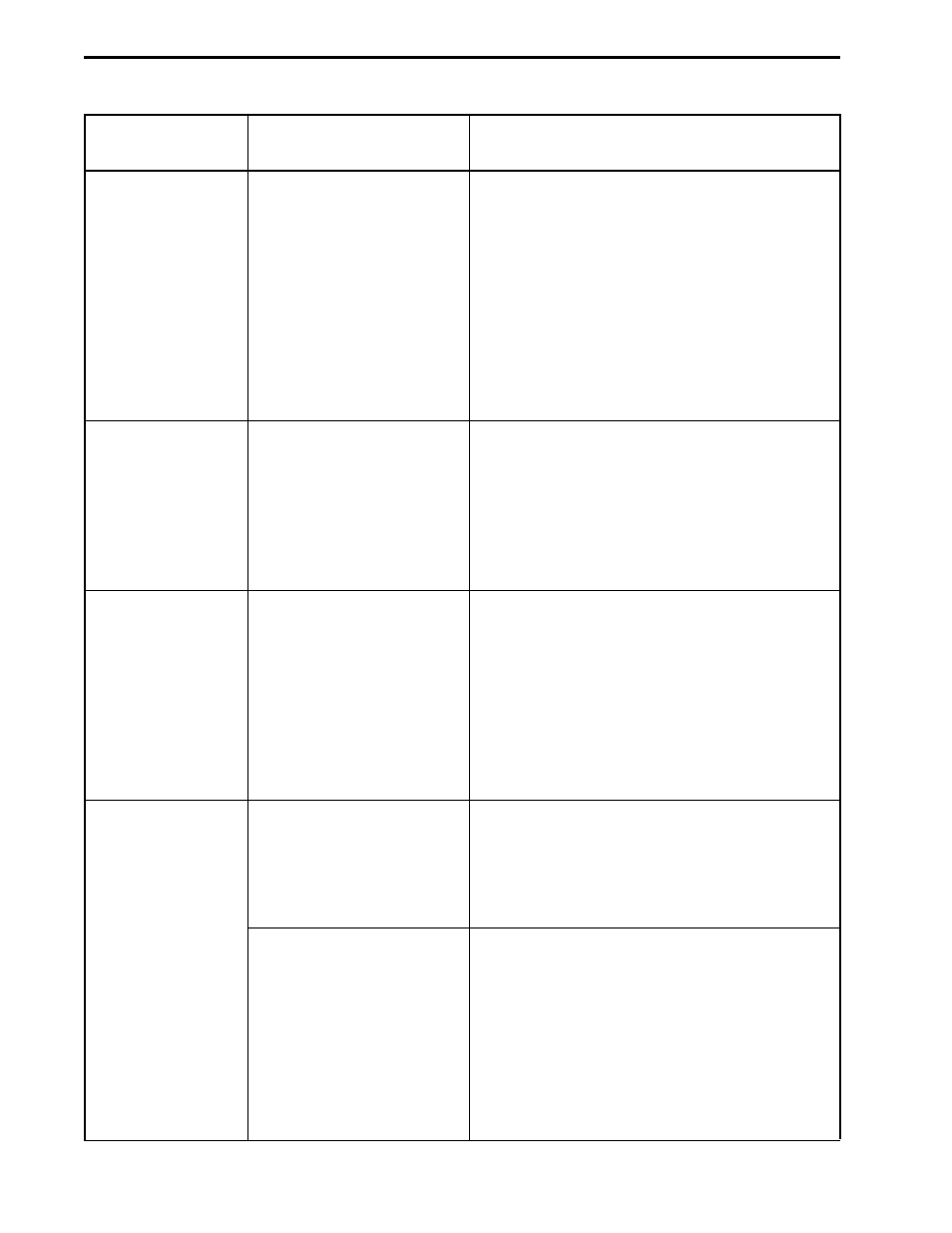

Problem

Possible Cause

Solution

Pump is not

Check valves are fouled and

delivering the

should be replaced.

correct flow rate

(continued)

The check valves should be

replaced on a regular basis,

depending on the usage and

type of solution or sample

pumped through the

pumphead. Refer to the

Maintenance section for more

information on how to replace

a check valve.

Liquid is continu-

The pump’s piston seals are

ously leaking from

worn or damaged.

the pumphead

washout drain

trough.

Erratic or reduced

Columns packed with soft gels

flow rate when

or large particles typically pro

pumping onto

duce very low back-pressures

columns which

when run at low flow rates.

produce low back-

pressures

(eg., Econo-Pac

®

cartridges or small,

agarose gel affinity

columns).

Loud or unusual

Residue buildup behind

noise coming from

piston seals.

the front of the

workstation.

Sticky pistons.

TROUBLESHOOTING

MAINTENANCE AND TROUBLESHOOTING

12-4

5. Clean (or replace) the check valves (see

Section 11.3.3, Routine Maintenance of the

Workstation Pumps.)

a. Cleaning: Sonicate check valves in a warm

detergent solution, rinse with DI water, and

re-install.

Replacing: Replace badly clogged or

damaged check valves.

b. Recalibrate the pumps after

cleaning/replacing check valves. Select

Gradient Pump Calibration from the

Utilities drop-down menu.

1. Replace the piston seals on both pumpheads.

Clean pistons and piston guides with water,

followed by methanol as a precautionary

maintenance step.

2. Recalibrate the pumps after changing seals by

selecting Gradient Pump Calibration from the

Utilities drop-down menu.

1. Insert the backpressure regulator between the

pump and the injection valve.

CAUTION: Low-pressure columns may burst

if the backpressure regulator is placed after

the column.

1. The pistons should be rinsed on a nightly basis.

This may easily be done automatically by

programming a water rinse step at the end of

each protocol. This may also be done manually

by washing the pistons with the syringe

provided in the Fittings kit.

2. Follow the maintenance procedure to carefully

remove and disassemble the pumpheads.

Wash the pistons thoroughly with water to

remov debris or salt crystals. If the piston seals

have many hours of use, they should be

replaced following the information in the

maintenance section. Ater re-assembly of the

pumpheads, pump 100 ml of 100% methanol

(MeOH) through each pumphead at 5 ml/min

with the 40 psi backpressure regulator in place.

- BioLogic DuoFlow Pathfinder 80 System DuoFlow™ Chromatography System BioLogic DuoFlow Pathfinder 20 System DuoFlow™ Chromatography System BioLogic DuoFlow Maximizer 80 System DuoFlow™ Chromatography System BioLogic DuoFlow Maximizer 20 System DuoFlow™ Chromatography System BioLogic DuoFlow QuadTec 40 System DuoFlow™ Chromatography System BioLogic DuoFlow QuadTec 10 System DuoFlow™ Chromatography System BioLogic DuoFlow 40 System Chromatography System BioLogic DuoFlow 10 System Chromatography System