INFICON MDC-360 Thin Film Deposition Controller User Manual

Page 136

MDC-360 DEPOSITION CONTROLLER

11-8

COMPUTER INTERFACE

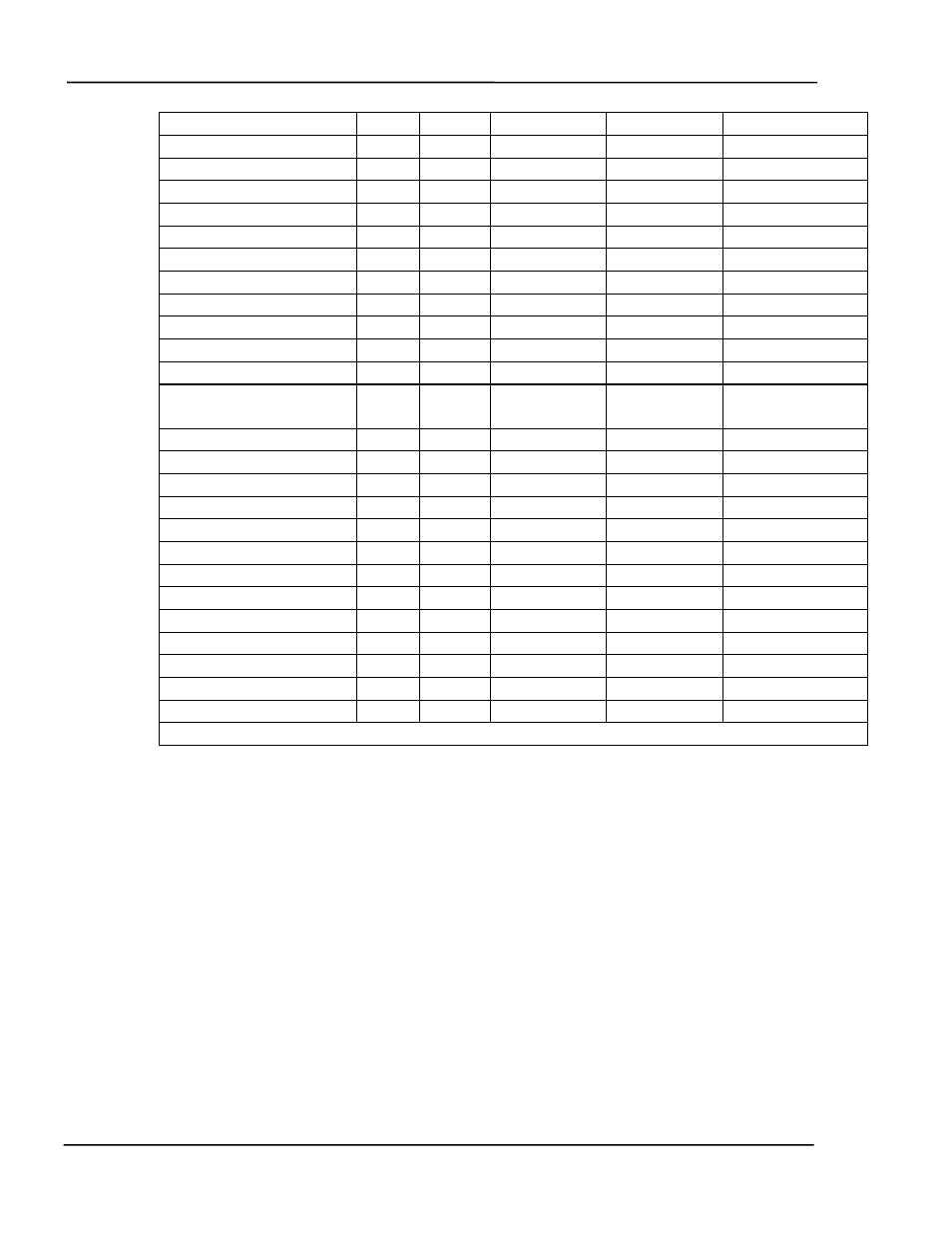

Deposition Rate #2

2

49

1

0-9999

0.1 Å/sec

Deposition Rate #3

2

51

1

0-9999

0.1 Å/sec

Deposition Rate #4

2

53

1

0-9999

0.1 Å/sec

Deposition Rate #5

2

55

1

0-9999

0.1 Å/sec

Time Setpoint

2

57

*

0-35999

Seconds

Ramp to Feed Time

2

59

*

0-35999

Seconds

Feed Power

2

61

1

0-999

0.1%

Feed Time

2

63

*

0-35999

Seconds

Ramp to Idle Time

2

65

*

0-35999

Seconds

Idle Power

2

67

1

0-999

0.1%

Maximum Power

2

69

1

0-999

0.1%

Minimum Power

2

71

1

0-999

0.1%

Rate Deviation

2

Attenti

73

1

0-999 0.1%

on

Rate Deviation Alarm

2

75

1

0-999

0.1%

Rate Deviation Abort

2

77

1

0-999

0.1%

Sample Period

2

79

*

0-35999

Seconds

Backup Tooling Factor

2

81

1

100-4999

0.1%

Ramp Start Thick. #1

3

83

3

0-999900

Å

Ramp Stop Thick #1

3

86

3

0-999900

Å

Ramp Start Thick. #2

3

89

3

0-999900

Å

Ramp Stop Thick #2

3

92

3

0-999900

Å

Ramp Start Thick. #3

3

95

3

0-999900

Å

Ramp Stop Thick #3

3

98

3

0-999900

Å

Ramp Start Thick. #4

3

101

3

0-999900

Å

Ramp Stop Thick #4

3

104

3

0-999900

Å

Mat

4

erial password

107

*

N/A

ASCII

Total 111 bytes

* - Indicates decimal point position is not applicable.

: Header, Address, Instruction=6,

gth=1, Mater

ruct the controller to send the parameter l

terial #15 the

ould send:

255)+Chr$(254)+Chr$

r$(1)+

(15)+Chr$(233)

#

ey

cter material

names.

Format

Len

ial #(0-31), Checksum.

Example: To inst

ist for ma

computer w

Chr$(

(1)+Chr$(6)+Ch

Chr$

8. Receive a material (Code #7)

Instructs the controller to enter all the incoming material parameters for material

n into memory. The parameters must be in the same order and format as the

above material parameter list.

Format: Header, Address, Instruction=7, Length=111, 1 byte, Material# (0-

31),110 bytes parameter data, Checksum.

9. Send material list (Code #8)

Instructs the controller to send a list of all material names in the order that th

are stored in the controller. The material list consists of 32 10 chara