INFICON MDC-360 Thin Film Deposition Controller User Manual

Page 135

MDC-360 DEPOSITION CONTROLLER

11-7

COMPUTER INTERFACE

Year 2

(0-99)

Total 12 byt

es

Example: To instruct the controller to send the t

e the computer would

send:

Chr$(255)+Chr$(2

hr$(1)+C

(4)+Ch

(251)

6. Receive time and date (Code #5)

Instructs the controller to enter the incoming time and date into memory. The

values must be in the order, range, and format lis

7. Send a material (Code #6)

r to send all the m

rial pa

terial # n to the

host computer. A description of the material para

ime and dat

54)+C

hr$

r$(0)+Chr$

ted above.

Instructs the controlle

ate

rameters for ma

meter list is in the table below:

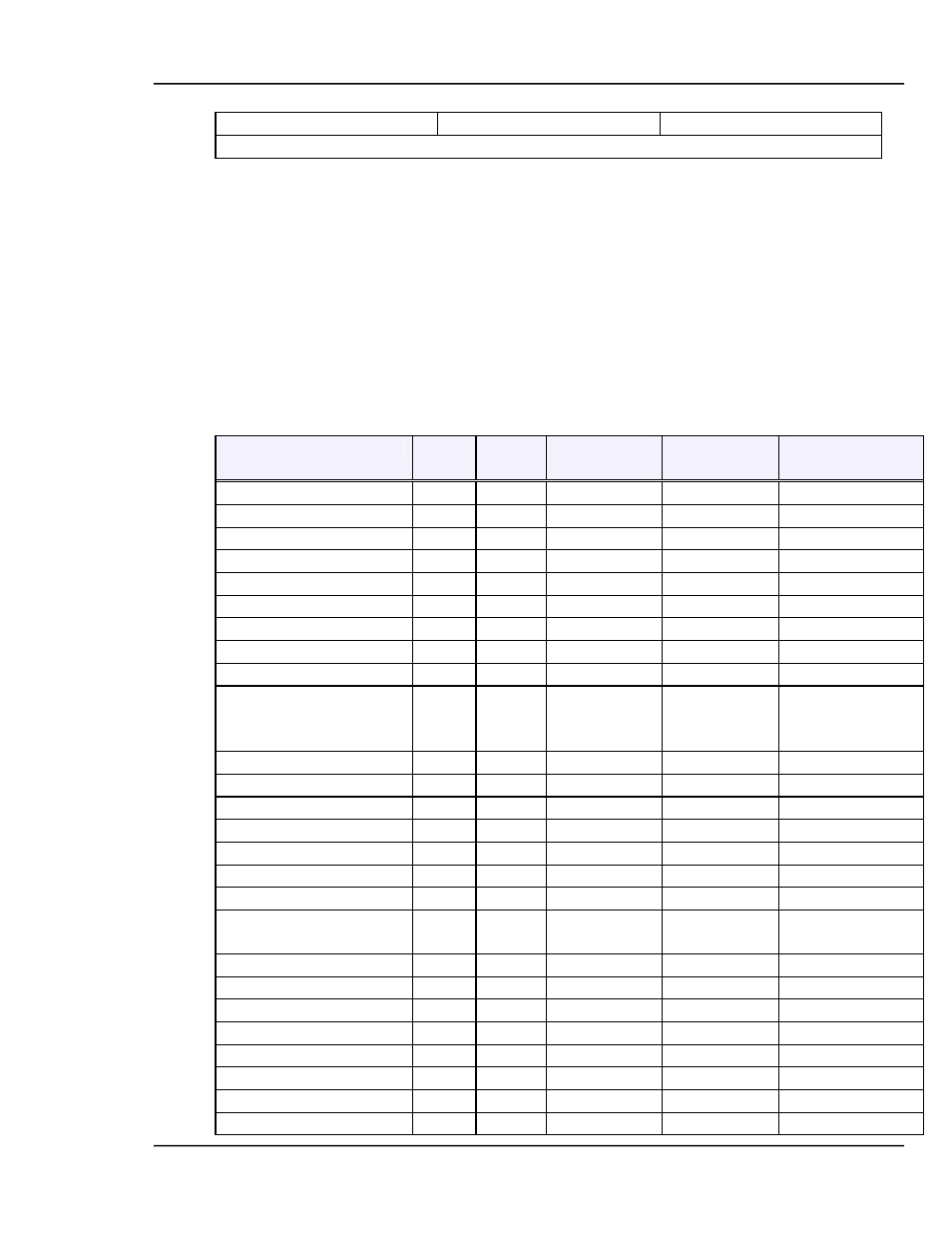

Parameter name

Len

bytes

Byte

Offset

Decimal Pt.

Position

Range

Units

Material #

1

0

(0-31)

No

*

ne

Material Name

0

*

1

1

Sensor #

1

11

*

(1-4)

None

Crystal #

1

12

*

(1-8)

None

Source #

1

13

*

(1-4)

None

Pocket #

1

14

*

(1-8)

None

Rate Establish Time

1

15

*

(0-99)

Seconds

Power Alarm Delay

1

16

*

(0-99)

Seconds

Sample

%

Dwell %

1

17

*

(0-100)

Crystal Fail

1

18

*

4 = Halt

5 =TimePwr

6 =Switch

Backup Sensor #

1

19

*

(1-4)

None

Backup Crystal #

1

20

*

(1-8)

None

Material Density

2

21

2

80-9999

0.01 gm/cm

3

Acoustic Impedance

2

23

2

400-5999

0.01 gm/cm

2

/sec

Tooling Factor

2

25

1

100-4999

0.1%

Proportional gain

2

27

*

1-9999

None

Integral Time constant

2

29

1

0-999

0.1 Seconds

Deri

2

nds

vative Time

constant

31

1

0-999 0.1

Seco

Rise to Soak Time

2

33

*

999

Seconds

0-35

Soak Power

2

35

1

0-999

0.1%

Soak Time

2

37

*

0-35999

Seconds

Rise to Predeposit Time

2

39

*

0-35999

Seconds

Predeposit Power

2

41

1

0-999

0.1%

Predeposit Time

2

43

*

9

Seconds

0-3599

Rate Establish Error %

2

0.1 Å/sec

45

1

0-999

Deposition Rate #1

2

0-9999

0.1 Å/sec

47

1