IAI America PCON-CF User Manual

Page 153

135

8. Parameter Settings

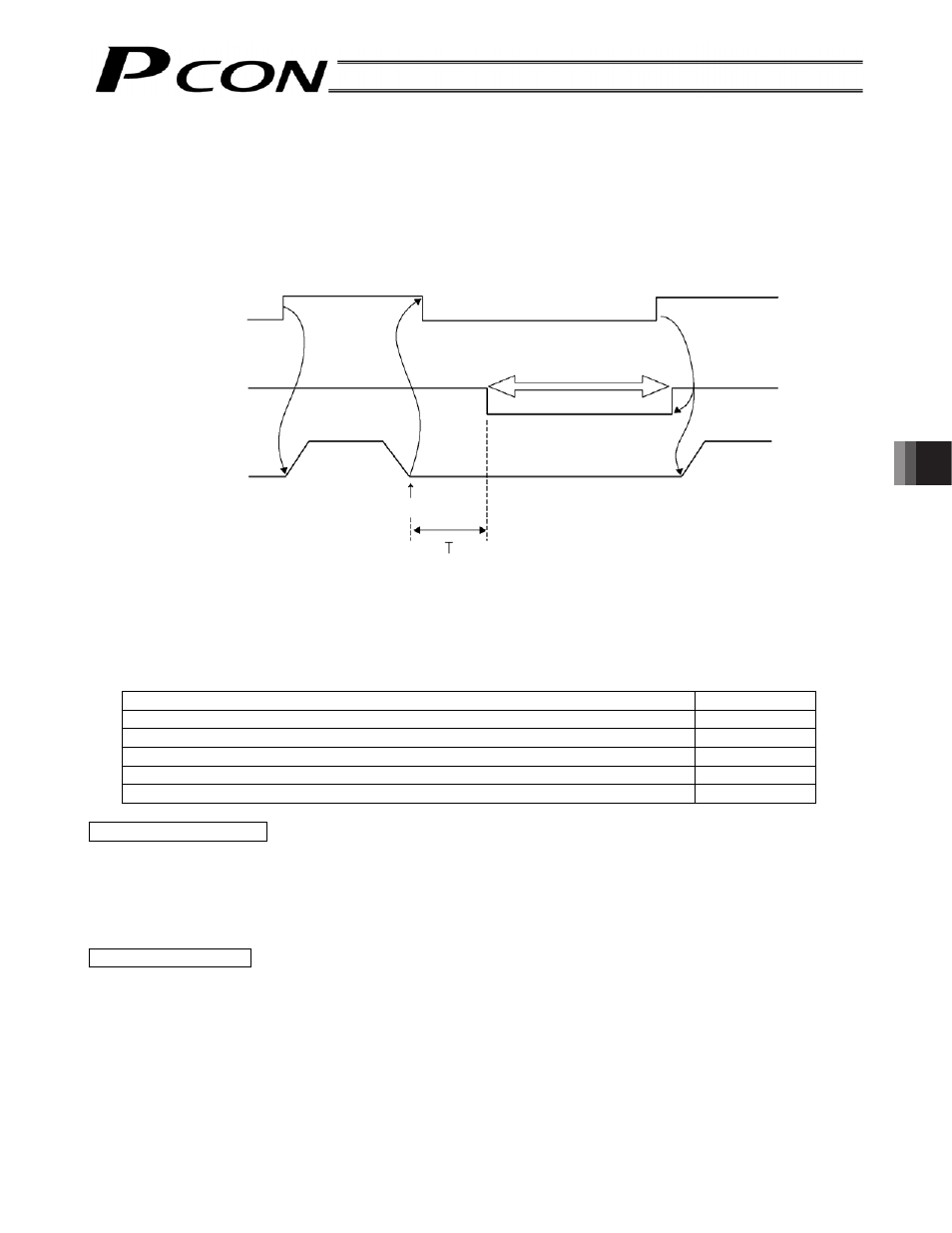

Move command

Servo status

Actuator movement

Servo on

Automatic servo-off mode

(A green LED blinks.)

Target position

T: Delay time (seconds) after

positioning is completed until the

servo turns off

z Automatic servo-off delay time (No.36 ASO1/No.37 ASO2/No.38 ASO3)

This parameter defines the delay time after the positioning is completed until the servo turns off automatically,

when the “Standstill mode” field of the position table is set to “1,” “2” or “3” (automatic servo-off control enabled)

or parameter No. 53 (Default standstill mode) is set to “1,” “2” or “3”(automatic servo-off control enabled).

Meaning of settings: 1: T becomes the value set by parameter No. 36.

2: T becomes the value set by parameter No. 37.

3: T becomes the value set by parameter No. 38.

The factory setting is “0 [sec].”

z Default standstill mode (No.53 HSTP)

[1] In PIO patterns 0 to 4, either the automatic servo-off mode or full servo control mode can be selected when

the actuator stands by for a long time after completing the home return effected by the HOME input signal.

[2] In PIO pattern 5, the full servo control mode can be selected when the actuator stands by for a long time

after the power has been turned on.

The factory setting is “0 [Disable].”

Setting

All power-saving modes are disabled.

0

Automatic servo-off mode. The delay time is defined by parameter No. 36.

1

Automatic servo-off mode. The delay time is defined by parameter No. 37.

2

Automatic servo-off mode. The delay time is defined by parameter No. 38.

3

Full servo control mode

4

Automatic servo-off mode

After positioning is completed, the servo will turn off automatically upon elapse of a specified time.

(Since no holding current flows, power consumption will decrease.)

When the next movement command is received from the PLC, the servo will turn on and the actuator will start

moving.

Refer to the above timing chart.

Full servo control mode

The pulse motor is servo-controlled to reduce the holding current.

Although the exact degree of current reduction varies depending on the actuator model, load condition, etc.,

the holding current decreases to approx. 1/2 to 1/4.

Since the servo remains on, position deviation will not occur.

The actual holding current can be checked in the current monitor screen of the PC software.