IAI America PCON-CFA User Manual

Page 185

4. SCON-CA

177

4.6.3

Position/Simplified Direct Value Mode (Number of Occupied Bytes: 8)

This is the operation mode with the position No. set up. Whether the target position is set directly the control

signals (PMOD signals), or the value registered on the position data is used can be selected.

For the speed, acceleration/deceleration and positioning band, etc., except for the target position, the

values in the position table within the controller are used. Setup the position data referring the operation

manual for the controller main body.

The settable No. of position data items is max 768 points.

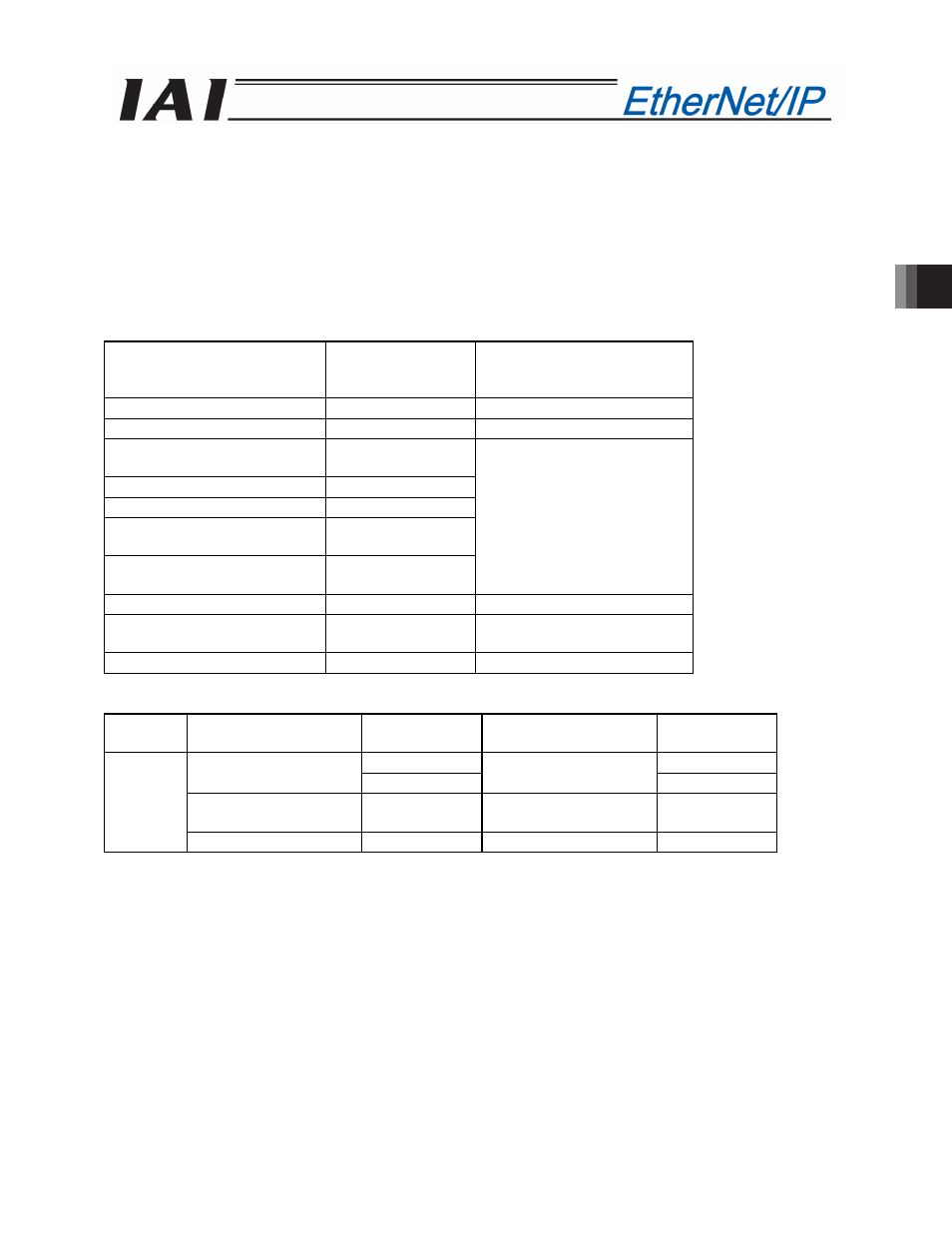

The robot cylinder's effective main functions that can be controlled using this mode, are as shown in the

following table.

ROBO cylinder function

{

: Direct control

U

: Indirect control

x: Disable

Remarks

Home-return operation

{

Positioning operation

{

Speed and acceleration /

deceleration setting

U

Pitch feed (inching)

U

Pressing Operation

U

Speed change during the

movement

U

Operation at different

acceleration and deceleration

U

These items must be set in

the position data table.

Pause

{

Zone signal output

U

Zones are set using position

data or parameters.

PIO pattern selection

x

(1) PLC address configuration (* “n” indicates the node address of each axis.)

Parameter

No.84

SCON-CA side

input register

PLC side output

address (bytes)

SCON-CA side

output register

PLC side input

address (bytes)

n+0, n+1

n+0, n+1

Target position

n+2, n+3

Current position

n+2, n+3

Specified position

number

n+4, n+5

Completed position No.

(Simple alarm code)

n+4, n+5

1

Control signal

n+6, n+7

Status signal

n+6, n+7

(Note) Be careful of using duplicated node addresses.