Danfoss vlt 2800 (fc protocol), Danfoss, Vlt 2800 (fc protocol) – Delta Electronics Network Device DOP-A/AE/AS User Manual

Page 26

Delta DOP Series HMI Connection Manual|DOP-A/AE/AS Series

Revision January, 2008, Doc. Name: 2007PDD23000007

1-25

Danfoss VLT 2800 (FC Protocol)

A. HMI factory setting

Baud rate: 9600, 8, Even, 1, RS-485.

PLC station number: 1.

Control area/status area: None / None.

NOTE

1) Delta HMI can be connected to for VLT-2800, 5000, 6000, 7000 controllers.

2) Each data length format of Danfoss AC drive parameter is not fixed, therefore, “Multiple Duplicate”

function is not provided.

3) Max. supported alarm number is 16. If the alarm number is over 16, a fault will occur.

4) Does not support “optimum read/write” characteristic.

5) If the selected element is a string, the minimum data length should be more than 2.

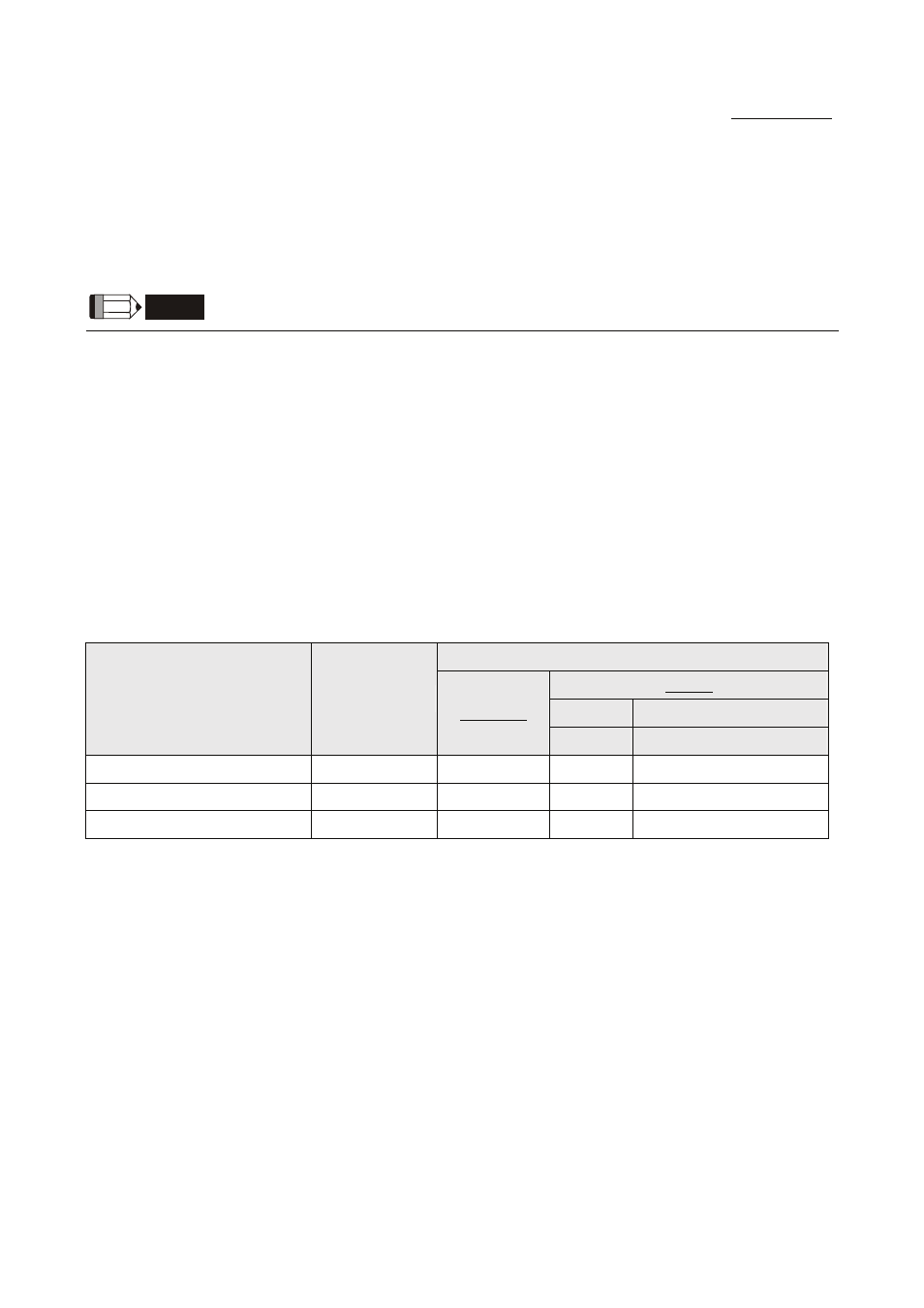

B. Definition of controller Read/Write address

Registers

Read/Write Range

Bit No.

Low Byte

High Byte

Register Type

Format

Word No.

Index No.

Parameter

Pn:I

n: 0 ~ 999

0

I: 0 ~ 31

Control Word

CTRWD

0

N/A

N/A

Status Word

STAWD

0

N/A

N/A

¾

Index No : If the index No. is not used, its default setting will be 0. The default setting of index No. for

parameter P606 ~ P617 is 1.

¾

Please notice that it is necessary to input the index No. when using some parameters of Danfoss

controllers. At this time, please pay close attention on the setting range of index number. If the setting

range is not started from 0, the parameter read & write failure will occur. For example, the index No.

setting range of the parameter P615 is from 1 to 20, if the users do not input the index No., the system

will assume the index number is 0 (default setting) and the a fault will occur when the users read or write

the parameter.

¾

CTRWD: Write-only. (Can not be used on the devices which can display the value or input value. It is

recommended to be used on the setting value/setting constant (button), or marco function.)

¾

STAWD: Read-only.

¾

Control & Status Word: Please refer to the explanation on the next page.