Good, Not allowed, Excellent – Delta BLD-E1 brushless DC motor drive BLD-E1 Series User Manual

Page 24

Chapter 2 Installation and Wiring| BLD-E1 Series

Revision May 2009, 00DE, V0.50

2-5

6.

With long motor cables between the brushless DC motor drive and motor, high capacitive

switching current peaks can cause over-current, high leakage current or lower current readout

accuracy. To prevent this, the motor cable should be less than 20m for 3.7kW models and

below. And the cable should be less than 50m for 5.5kW models and above. For longer motor

cables use an AC output reactor.

7.

The brushless DC motor drive, electric welding machine and the greater horsepower motor

should be grounded separately.

8.

Use ground leads that comply with local regulations.

9.

No brake resistor is built in the BLD-E1 series, it can install brake resistor for those occasions

that use higher load inertia or frequent start/stop. Refer to Appendix B for details.

10. To prevent the lightening strike and electric shock, the metal grounding wire of electric

equipment should be thick, short and connect to the specific ground terminal of the variable

frequency system.

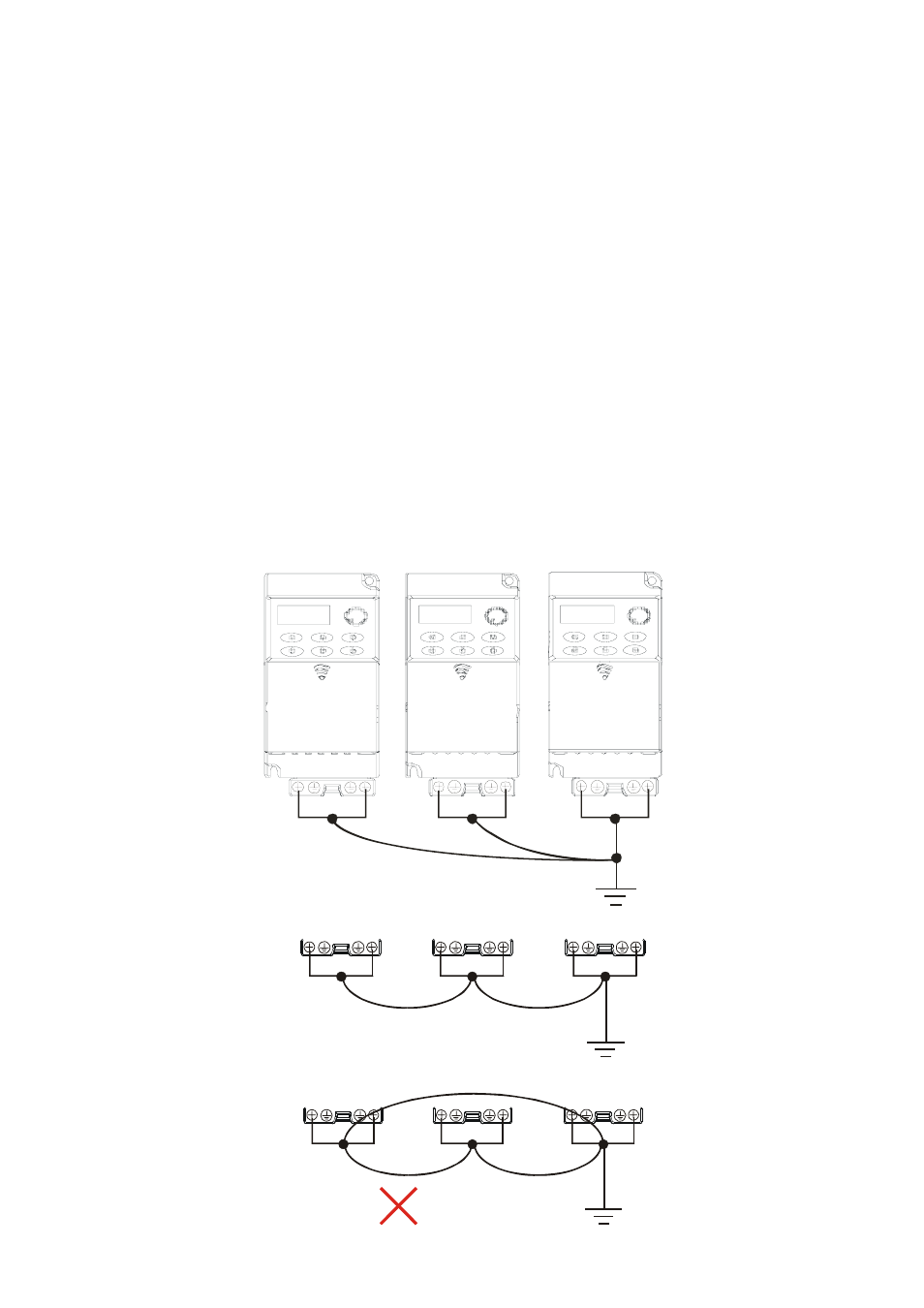

11. Multiple BLD-E1 units can be installed in one location. All the units should be grounded directly

to a common ground terminal, as shown in the figure below. Ensure there are no ground

loops.

Excellent

Good

Not allowed