12 technical data of standard design, 1 iec design with connection voltages 380 vac, 1 iec design with connection voltages 380 v – Metalfab SEW Eurodrive MOVIMOT MM..C User Manual

Page 149

Operating Instructions – MOVIMOT® MM03C - MM3XC

149

12

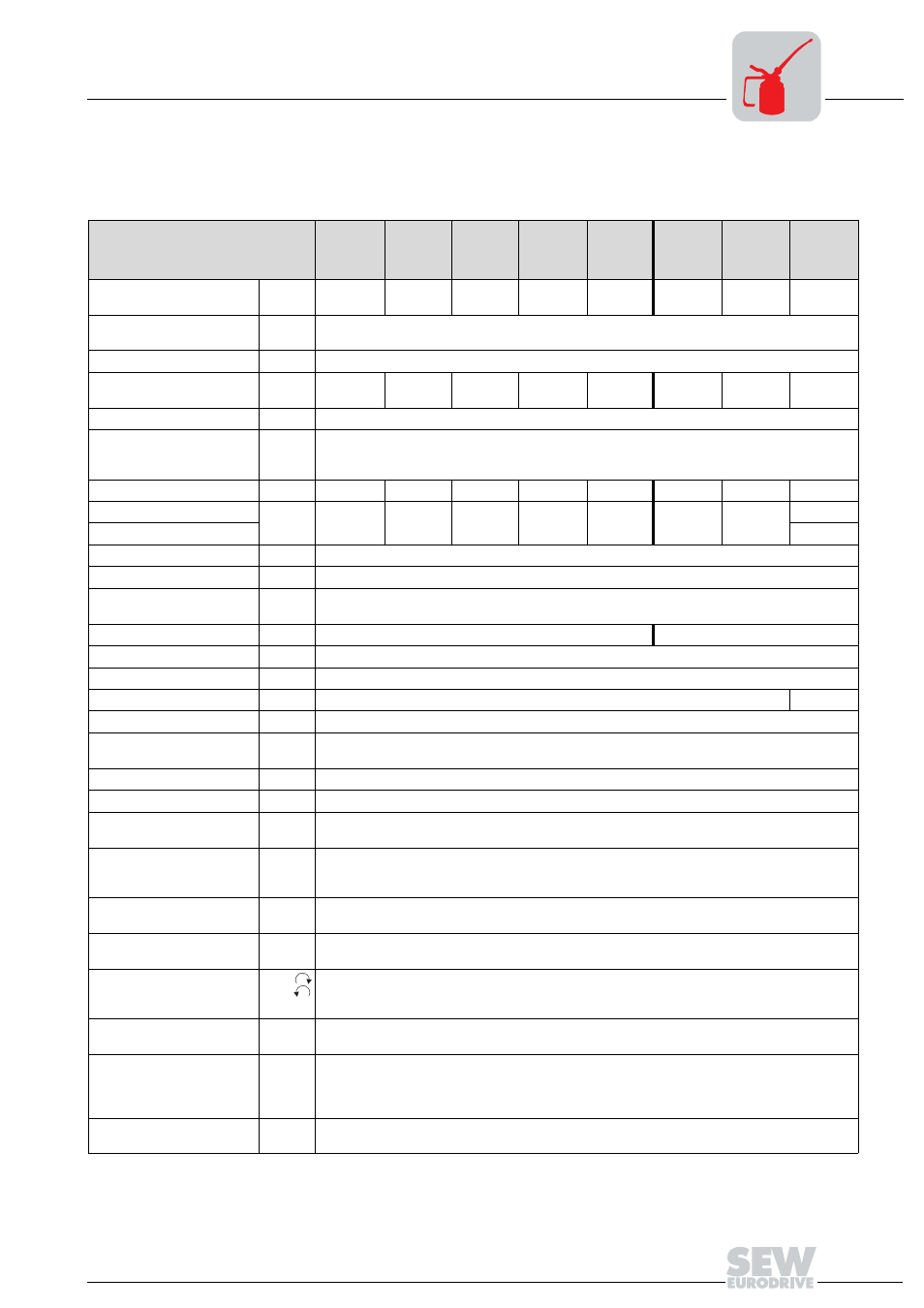

IEC design with connection voltages 380...500 VAC

Technical Data of Standard Design

12

Technical Data of Standard Design

12.1

IEC design with connection voltages 380...500 V

AC

MOVIMOT

®

type

MM 03C-

503-00

MM 05C-

503-00

MM 07C-

503-00

MM 11C-

503-00

MM 15C-

503-00

MM 22C-

503-00

MM 30C-

503-00

MM 3XC-

503-00

Part number

824 115 5

824 116 3

824 117 1

824 118 X

824 119 8

824 120 1

824 121 X

824 180 5

Apparent output power at

V

mains

= 380...500 V

AC

P

rated

1.1 kVA

1.4 kVA

1.8 kVA

2.2 kVA

2.8 kVA

3.8 kVA

5.1 kVA

6.7 kVA

Connection voltages

Permitted range

V

mains

3 x 380 V

AC

/ 400 V

AC

/ 415 V

AC

/ 460 V

AC

/ 500 V

AC

V

in

= 380 V

AC

-10 % ... 500 V

AC

+10 %

Supply frequency

f

mains

50 Hz ... 60 Hz

±

10 %

Rated system current

(at V

mains

= 400 V

AC

)

I

mains

1.3 A

AC

1.6

A

AC

1.9

A

AC

2.4

A

AC

3.5

A

AC

5.0 A

AC

6.7 A

AC

8.6 A

AC

Output voltage

V

out

0...V

in

Output frequency

Resolution

Operating point

f

out

2...100 Hz

0.01 Hz

400 V at 50 Hz / 100 Hz

Rated output current

I

rated

1.6 A

AC

2.0

A

AC

2.5

A

AC

3.2

A

AC

4.0

A

AC

5.5 A

AC

7.3 A

AC

9.6 A

AC

Motor power S1

P

mot

0.37 kW

0.55 kW

0.75 kW

1.1 kW

1.5 kW

2.2 kW

3.0 kW

3.0 kW

Motor power S3 25 % cdf

4.0 kW

PWM frequency

4 (factory setting) / 8 / 16

1)

kHz

1) 16 kHz PWM frequency (low-noise): When DIP SWITCH S1/7 = ON, the units operate with a 16 kHz PWM frequency (low noise) and switch

back in steps to lower switching frequencies depending on the heat sink temperature.

Current limitation

I

max

Motor: 160 % at

ᛴ

and

Ħ

regenerative: 160 % at

ᛴ

and

Ħ

Maximum motor lead

length

15 m when mounting the MOVIMOT

®

frequency inverter close to the motor

(with SEW hybrid cable and option P2.A)

External braking resistor

R

min

150

Ω

68

Ω

Interference immunity

Meets EN 61800–3

Interference emission

Meets EN 61800–3 and class A limit to EN 55011 and EN 55014

Ambient temperature

ϑ

amb

-25 °C...40 °C (P

rated

reduction: 3 % I

N

per K to max. 60 °C)

2)

2) -25 °C...40 °C with S3 25% ED (up to 60 °C with S3 10 % ED)

Climate class

3 K3

Enclosure

(motor-dependent)

IP54, IP55, IP65, IP66 (options, specify when ordering)

IP67 (only available for inverters with terminal box)

Operating mode

DB (EN 60149-1-1 and 1-3), S3 max. cycle duration 10 minutes

Cooling type (DIN 41 751)

Self-cooling

Altitude

h

≤

1000 m (P

rated

reduction: 1 % per 100 m starting at an altitude of 1000 m, see also the section

"Electrical Installation – Installation Instructions")

Ext. power supply to elec-

tronics

Tl. 24 V

V = +24 V

±

25 %, EN 61131-2, residual ripple max. 13 %

I

in

≤

250 mA (typ. 150 mA at 24 V)

Input capacitance 100

µ

F

3 binary inputs

Isolated by opto-coupler, PLC-compatible (EN 61131-2)

R

i

≈

3.0 k

Ω

, I

in

≈

10 mA, sampling time

≤

5 ms

Signal level

+13 V...+30 V = "1" = Contact closed

-3 V...+5 V = "0" = Contact open

Control Functions

Tl. R

Tl. L

Tl. f1/f2

CW/Stop

CCW/Stop

"0" = Setpoint 1 / "1" = Setpoint 2

Output relay

Contact data

Tl. K1a

Tl. K1b

Response time

≤

15 ms

24 V

DC

/ 0.6 A

DC

/ DC11 to IEC 337-1

Signaling function

Normally open contact for ready

signal

Contact made:

– with applied voltage (24 V + supply)

– if no fault was detected

– after self-test phase concluded (after switch-on)

Serial interface

Tl. RS+

Tl. RS-

RS-485