Changing the braking torque – Metalfab SEW Eurodrive MOVIMOT MM..C User Manual

Page 147

Operating Instructions – MOVIMOT® MM03C - MM3XC

147

11

Inspection and maintenance work on the brake

Inspection and Maintenance

Changing the

braking torque

The braking torque can be adjusted in steps (see page 148).

•

by installing different brake springs,

•

by changing the number of brake springs.

1. Isolate MOVIMOT

®

from the supply, safeguarding it against unintentional power-up.

2. Remove the following:

– NV16 / NV26 proximity sensor, flange cover or fan guard (21), snap ring (20) and

fan (19), if available.

3. Remove the rubber sealing collar (5).

Remove the manual brake release: Setting nuts (18), conical coil springs (17), studs

(16), releasing lever (15).

4. Loosen the hex nuts (10e) and pull off the brake coil body (12) by approximately 50

mm (caution: brake cable!).

5. Change or add brake springs (11). (Position the brake springs symmetrically.)

6. Re-install brake components except for rubber sealing collar, fan and fan guard. Set

working air gap (see page 145, Points 5 to 7).

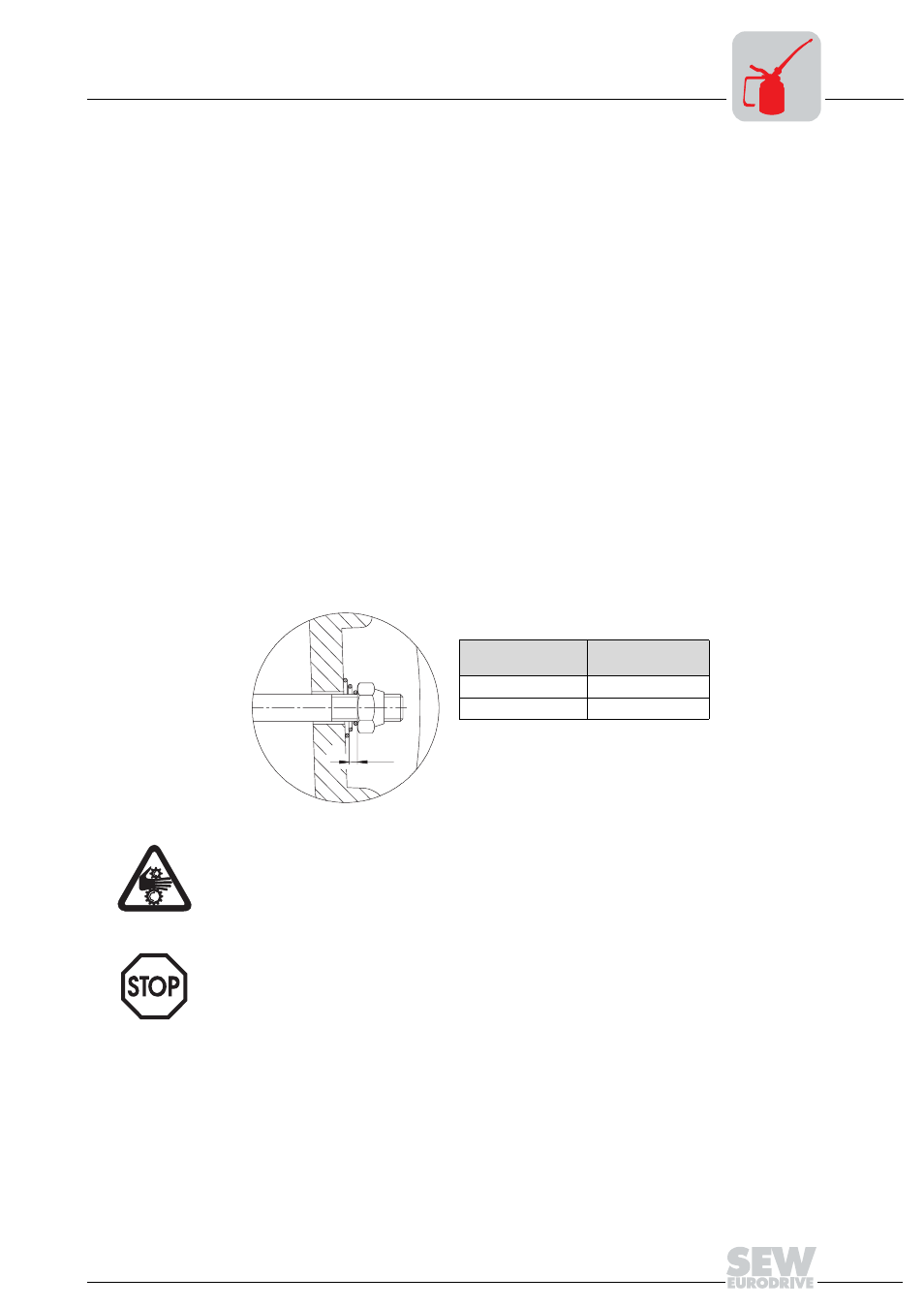

7. With manual brake release:

Set the floating clearance between the conical coil springs (pressed flat) and release

lever via the setting nuts (see the following figure).

8. Install the rubber sealing collar back in place and re-install the removed parts.

01111AXX

Brake

Floating clear-

ance s [mm]

BMG 05 - 1

1.5

BMG 2 - BMG 4

2

s

Important: This floating clearance is necessary so that the pressure plate can

move up as the brake lining wears.

Note: Install new setting nuts (18) and hex nuts (10e) if the removal procedure is

repeated! (due to reduced self-locking of nuts!).