Table of faults – Metalfab SEW Eurodrive MOVIMOT MM..C User Manual

Page 128

128

Operating Instructions – MOVIMOT® MM03C - MM3XC

10

Diagnostics of MOVIMOT® standard design

Diagnostics

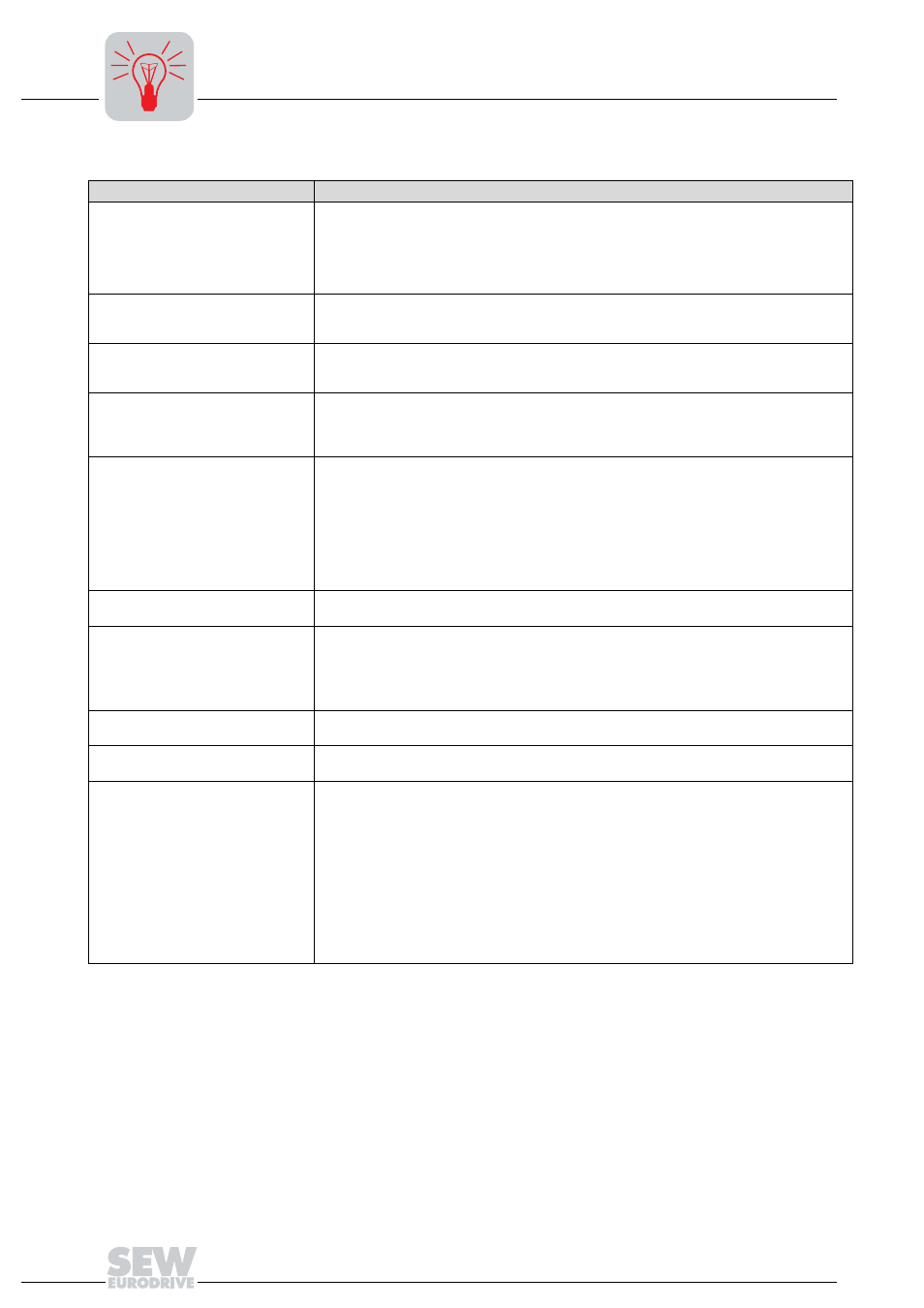

Table of faults

Faults

Cause / solution

Timeout of communication (motor

comes to a stop without error code)

A

Missing connection

⊥

, RS+, RS- between MOVIMOT

®

and RS-485 master.

Check the connection, in particular the ground, and repair.

B

EM interference. Check the shielding of the data cables and improve if necessary.

C

Incorrect type (cyclical) in acyclical protocol time between the individual messages.

Messages >1 s with protocol type "cyclical." Shorten message cycle or

select "acyclical."

DC link voltage too low, supply sys-

tem off detected

(motor stops, without fault code)

Check power cables and supply voltage for interruption. Motor restarts automatically as soon as

the supply voltage reaches normal values.

Fault code 01

Overcurrent of output stage

Short circuit of inverter output.

Check the connection between inverter output and motor for short circuit.

Reset the fault by switching off the 24 V

DC

supply voltage or use MOVILINK

®

.

Fault code 06

Phase fault

(The fault can only be recognized with

a load on the drive)

Check power cables for phase fault. Reset the fault by switching off the 24 V

DC

supply voltage or

use MOVILINK

®

.

Fault code 07

DC link voltage too high

A

Ramp time too short

→

Increase ramp time.

B

Faulty connection between brake coil and braking resistor.

→

Check the connection between braking resistor and brake coil. Correct, if necessary.

C

Incorrect internal resistance of brake coil/braking resistor

→

Check the internal resistance of the brake coil/braking resistor

(see the section "Technical Data").

D

Thermal overload in braking resistor

→

Wrong size of braking resistor selected.

Reset the fault by switching off the 24 V

DC

supply voltage or use MOVILINK

®

.

Fault code 08

Speed monitoring

Speed monitoring tripped, load of drive is too high

→

Reduce the load of the drive.

Reset the fault by switching off the 24 V

DC

supply voltage or use MOVILINK

®

.

Fault code 11

Thermal overload of the output

stage or internal unit fault

•

Clean the heat sink

•

Reduce the ambient temperature

•

Prevent heat accumulation

•

Reduce the load on the drive

Reset the fault by switching off the 24 V

DC

supply voltage or use MOVILINK

®

.

Fault code 17 to 24, 37

CPU fault

Reset the fault by switching off the 24 V

DC

supply voltage or use MOVILINK

®

.

Fault code 25, 94

EEPROM error

Reset the fault by switching off the 24 V

DC

supply voltage or use MOVILINK

®

.

Fault code 84

Thermal overload of motor

•

With shouldered assembly of the MOVIMOT

®

inverter, set DIP switch S1/5 to "ON".

•

For combinations of "MOVIMOT

®

and motor with one lower power increment," check the

position of DIP switch S1/6.

•

Reduce the ambient temperature

•

Prevent heat accumulation

•

Reduce the load on the motor

•

Increasing the speed

•

Check the combination of the drive and MOVIMOT

®

frequency inverter if the fault is signaled

shortly after the first release.

•

The temperature monitoring in the motor (TH winding thermostat) has tripped with the use of

MOVIMOT

®

and selected special function 5

→

Reduce load on the motor.

Reset the fault by switching off the 24 V

DC

supply voltage or use MOVILINK

®

.