11 inspection and maintenance, 1 inspection and maintenance periods, 11 inspection – Metalfab SEW Eurodrive MOVIMOT MM..C User Manual

Page 141: Maintenance

Operating Instructions – MOVIMOT® MM03C - MM3XC

141

11

Inspection and maintenance periods

Inspection and Maintenance

11

Inspection and Maintenance

11.1

Inspection and maintenance periods

•

Only use genuine spare parts in accordance with the valid parts list!

•

Danger of burns: Motors can become very hot during operation!

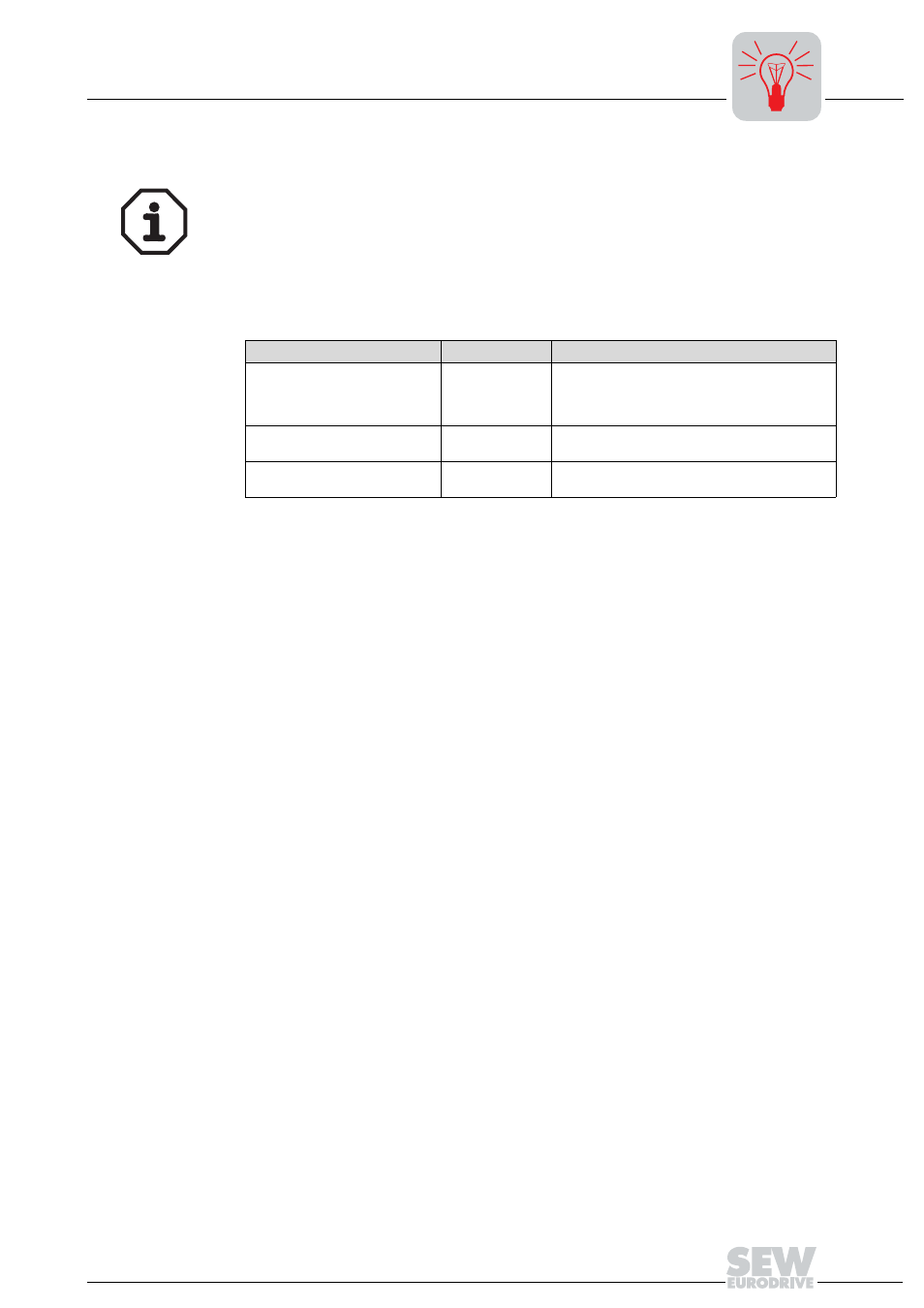

Frequency

Unit/Unit part

What to do

Depending on loading conditions:

Every 2 to 4 years

1)

1) The periods of wear are affected by many factors and may be short. Calculate the required inspection

and maintenance intervals separately in accordance with the project planning documents.

Brake

•

Inspect the brake (working air gap, brake

disk, pressure plate, carrier / gearing, pres-

sure rings)

•

Extract the abraded matter

Every 10,000 operating hours

Motor

•

Inspect motor (replace ball bearing/oil seal)

•

Clean the cooling air passages

Varies

(depending on external factors)

Motor

•

Touch up or renew the anticorrosion coating