Operator’s seat and seat belt – SkyTrak 3606 Service Manual User Manual

Page 95

Cab, Covers and Mirrors

4-9

20. Connect the battery negative (-) ground cable

21. Carefully examine all cab components, fasteners,

etc., one last time before engine start-up. Rectify any

faulty conditions.

22. Start the engine and check the operation of all

controls. Check for hydraulic fluid leaks. Check the

hydraulic fluid level in the tank and add fluid as

required.

4.2.3 Operator’s Seat and Seat Belt

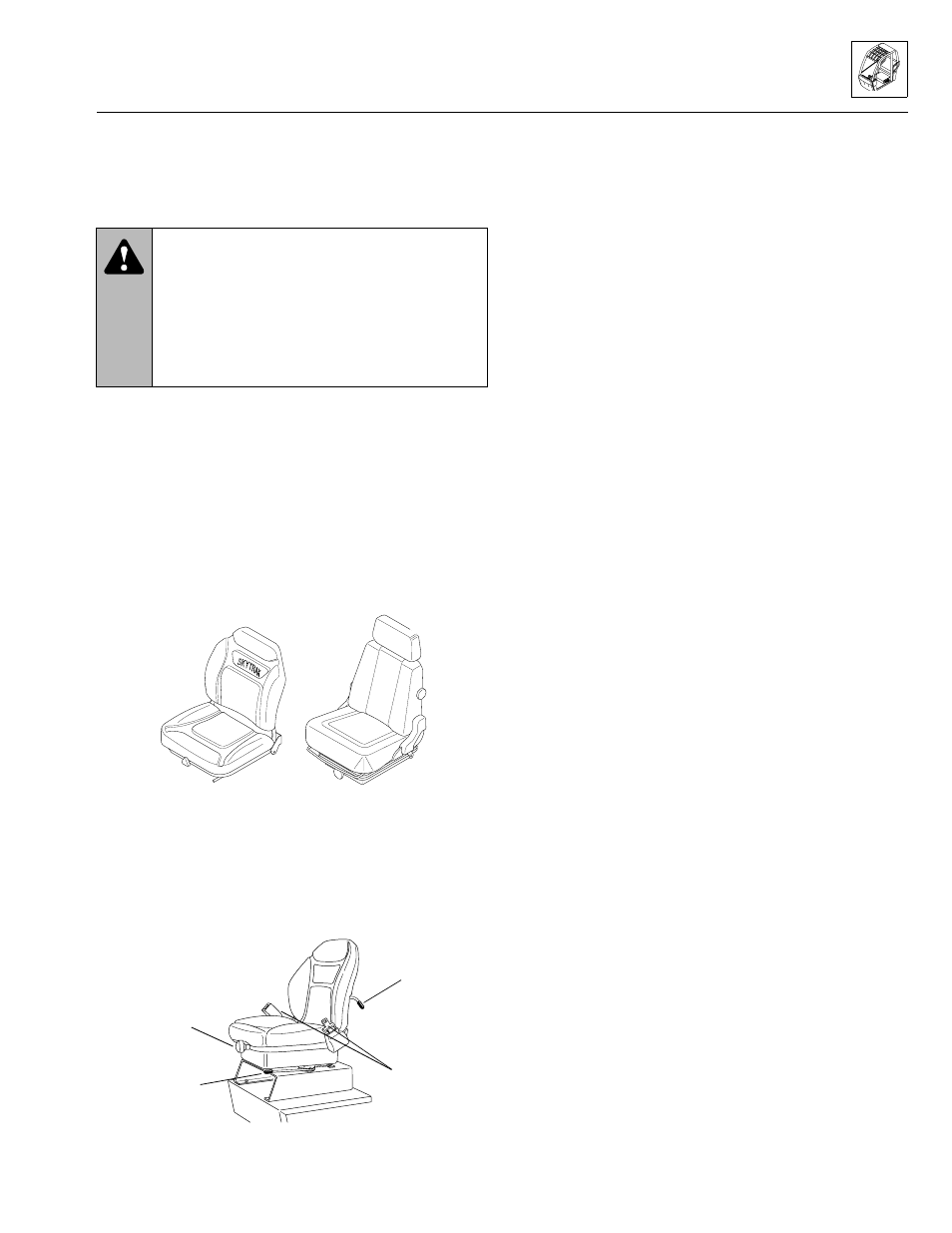

Three types of operator’s seats are used. These include

the standard operator’s seat (Fig. 4–7), and two optional

seats that include a headrest and are covered in either

deluxe vinyl or deluxe cloth material and include head-

rests. The seat belt is attached to the seat assembly.

Figure 4–7. Seat styles include standard and optional.

The seat assembly consists of upper (backrest) and

lower (bottom) cushions mounted on an adjustable sus-

pension unit (Fig. 4–8). Three seat adjustments can be

made: fore and aft position, suspension stiffness and

backrest angle. Seat adjustment information is contained

in the owners/operators manual.

Figure 4–8. Seat positions and stiffness can be adjusted.

An optional three-inch wide seat belt is available for

those locations that require a three-inch seat belt.

A. Seat Replacement

The seat can be removed from the cab by removing the

fasteners, including two tether cables, which secure the

seat to the cab. The seat belt is also easily removed by

removing the nuts, spacers, washers and capscrews

securing it to the seat frame. The seat tethers are

secured to the seat with the seat belt capscrews.

The seat and seat slides may be removed from the sus-

pension unit and mounting plate by removing four lock

nuts and flat washers that attach the seat slides to the

suspension unit.

Standard Seat Removal

Working from the outside rear of the cab, remove the rear

cab panel (item 3 in the General Overview illustration) to

gain access to the seat tether mounting hardware. The

rear cab panel is secured to the cab with 5/16-18 button-

head capscrews (4), 5/16" flat plastic washers (5) and

5/16-18 retaining nuts (6).

Note: Early production operator’s cabs included a

threaded hole for tether mounting. In Fig. 4–9, items 13

through 16 are not used on early production cabs.

1. Remove the 3/8-16 hex-lock elastic nuts

(16, Fig. 4–9) and rebound washers (15) securing the

tethers (2) to the rear of the cab.

Note: ALWAYS replace elastic-lined nuts with new

elastic-lined nuts to help ensure proper fastening.

2. Access to the right-side tether is restricted due to the

close proximity of the seat to the cab wall. Move the

seat all the way forward, and tip the seat back all the

way forward to gain access as needed to the tether

mounting hardware from inside the cab. If necessary,

remove the seat base mounting hardware before

removing the right-side tether.

Note: Early production operator’s cabs included a

threaded hole for tether mounting. In Fig. 4–9, items 13

through 16 are not used on early production cabs.

3. Remove four 5/16-18 hex-lock elastic nuts

(12, Fig. 4–9) and four 5/16 flat narrow washers

securing the seat (1) to the seat support (9).

Note: ALWAYS replace elastic-lined nuts with new

elastic-lined nuts to help ensure proper fastening.

4. Carefully remove the seat (Fig. 4–9) from the cab.

Remove the seat belt assembly and tethers (or

transfer these parts to the replacement seat) with the

seat out of the cab.

WARNING: DO NOT use your hand or any

part of your body to check for hydraulic leaks.

Hydraulic oil leaking under pressure can pene-

trate the skin and cause severe personal injury.

When checking for hydraulic leaks, wear safety

glasses and gloves to help provide protection

from spraying hydraulic oil. Use a piece of card-

board or paper to search for leaks.

MS0890

Standard

seat

Optional

seats

OS0200

Suspension

adjustment

knob

Fore & aft

adjustment

handle

Backrest angle

adjustment lever

Seat

belt

Model 3606 • Origin 10/99