Der (1, fig. 9– 75, 1, fig. 9– 75, Side tilt carriage cylinder legend – SkyTrak 3606 Service Manual User Manual

Page 308

Section 9

9-114

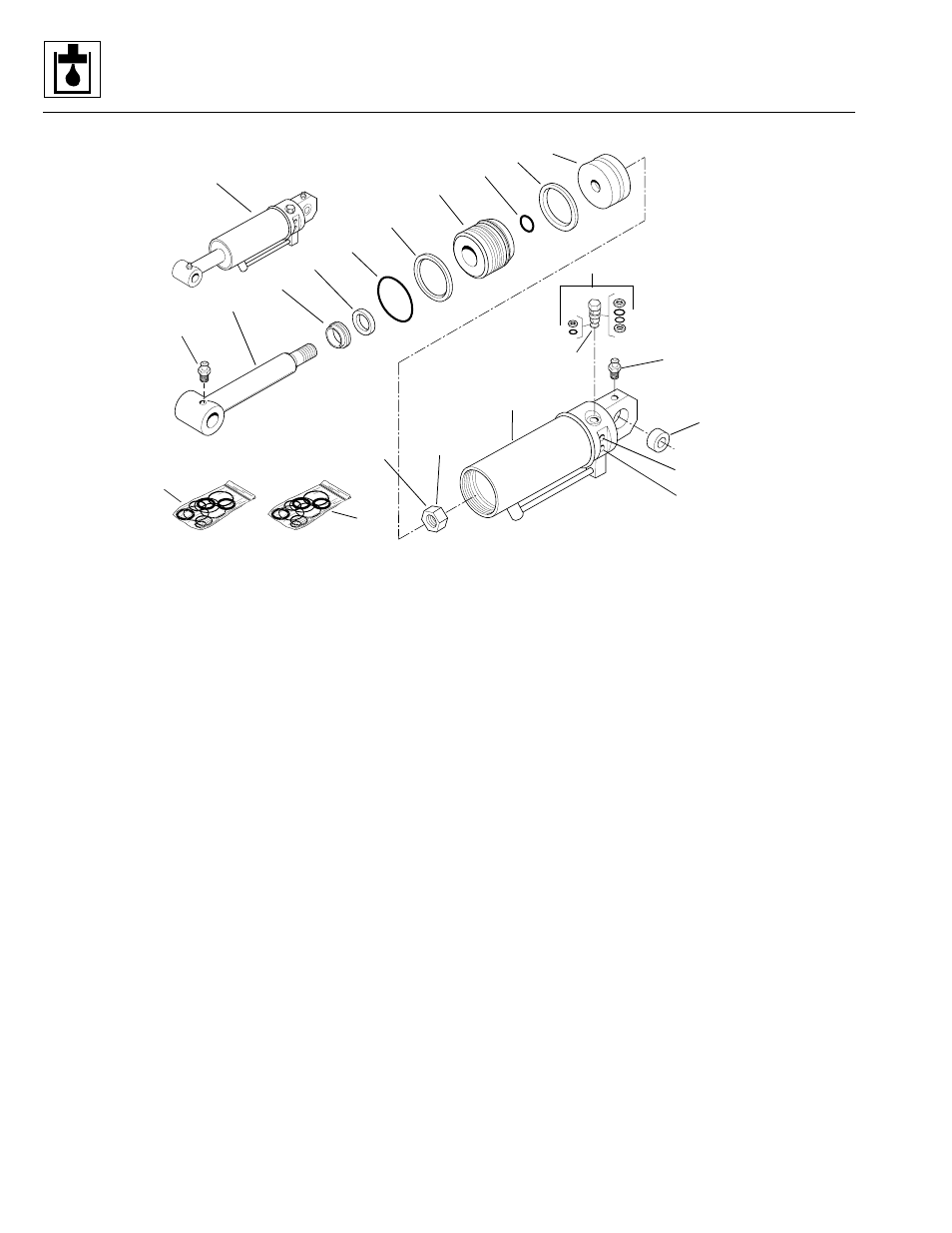

Figure 9– 75. Side tilt carriage cylinder (optional).

Side Tilt Carriage Cylinder Legend

1. Side Tilt Carriage Cylinder (OPTIONAL)

2. Cylinder Tube

3. Pilot Check Valve

4. Piston

5. Gland

6. Rod

7. Piston Nut

8. Self-aligning Bearing

9. Rod Seal

10. Wiper

11. O-Ring

12. Backup Ring

13. O-Ring

14. Piston Seal

15. Grease Fitting

KITS

16. Side Tilt Carriage Cylinder Seal Kit

(includes items 9-14)

17. Pilot Check Valve Seal Kit for item 3

b. Side Tilt Carriage Cylinder Disassembly

Note: An additional O-ring may be included at the base

of the cylinder rod. This additional O-ring may be

discarded, as it served only in a temporarily protective

role to keep paint off the rod while the cylinder was

painted at the factory.

1. Clean the side tilt carriage cylinder (1, Fig. 9– 75) with

a suitable cleaner to remove dirt, debris, grease, etc.

2. If necessary, remove both grease fittings (15) from

the cylinder tube eyelet.

3. If necessary, press the self-align bearing (8) from the

cylinder tube eyelet.

4. Place the side tilt carriage cylinder (1) in a soft-jawed

vise or other acceptable holding equipment if

possible. DO NOT damage the tube (2).

Note: Significant pressure may be trapped inside the

cylinder. Exercise caution when removing the pilot check

valves (3) from the side tilt carriage cylinder.

5. Remove both pilot check valves (3) from the side tilt

carriage cylinder. Remove the O-rings and backup

rings from the pilot check valves.

6. Extend the rod (6) to allow access to the base of the

cylinder.

PH0800

Apply Loctite #271 to

Threads and Torque to

350 lb/ft. (474,6 Nm)

Torque to 30-35 lb/ft.

(40,7-47,5 Nm)

Extend Port

Retract Port

PF0760

Model 3606 • Origin 10/99