SkyTrak 3606 Service Manual User Manual

Page 377

Electrical System

10-59

Model 3606 • Origin 10/99

Examine the fluid in the hydraulic oil sight glass

(Fig. 10– 61) to check whether there is a sufficient

amount of fluid in the system (the oil level should be at

the bottom of the sight glass with all hydraulic cylinders

retracted) and whether the fluid is contaminated. Replace

the hydraulic oil filter as required.

Figure 10– 61. Examine the fluid in the

hydraulic oil sight glass.

a. Hydraulic Oil Filter Pressure Switch Removal

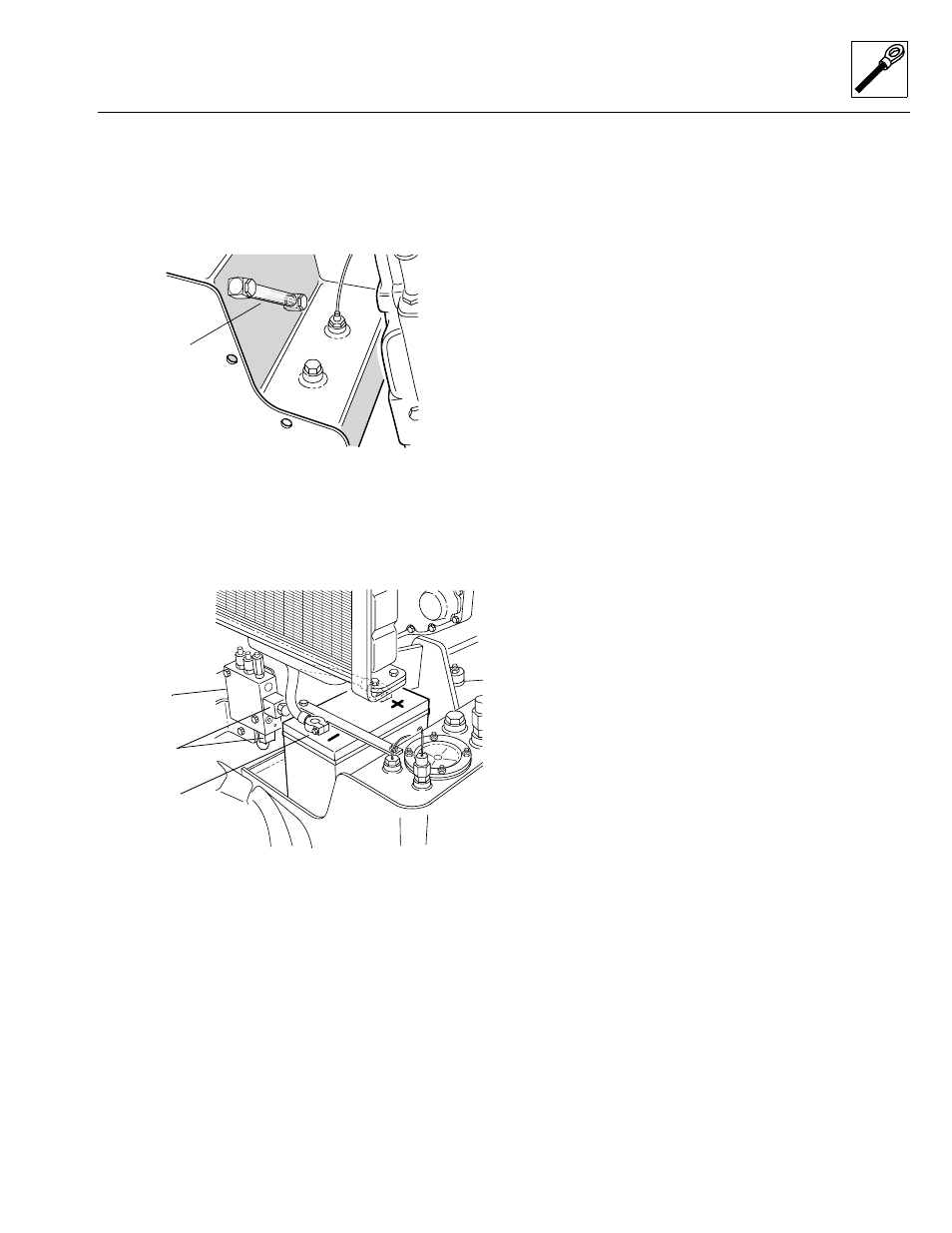

1. Disconnect the negative (-) battery cable at the

negative battery terminal (Fig. 10– 62).

Figure 10– 62. Disconnect the negative (-) battery cable

at the negative (-) battery terminal.

2. Label and disconnect the hydraulic oil filter pressure

switch wiring connectors.

3. Unthread the switch from the hydraulic reservoir.

b. Disassembly

DO NOT disassemble the hydraulic oil filter pressure

switch. Replace a defective or faulty switch with a new

one.

c. Cleaning and Drying

DO NOT submerge the hydraulic oil filter pressure switch.

Clean only with an approved solvent and dry with a

clean, lint-free cloth.

d. Inspection and Replacement

Inspect switch wiring for continuity and shorting. Replace

a defective or faulty switch with a new one.

e. Installation and Testing

1. Thread the hydraulic oil filter pressure switch into its

welded fitting on the hydraulic reservoir. Tighten

securely.

2. Connect the switch wiring connector leads for the

wiring harness and for the hydraulic oil temperature

switch.

3. Connect the negative (-) battery cable to its battery

terminal (Fig. 10– 62).

4. Clear the area around the vehicle of personnel and

any obstructions to vehicle travel.

5. Start the engine, check for hydraulic fluid leaking at

the hydraulic oil filter pressure switch, and allow the

hydraulic fluid to reach operating temperature.

6. Cycle the boom several times and check whether the

hydraulic oil filter restriction indicator illuminates on

the operators display panel.

10.8.7 Hydraulic Oil Temperature Switch

The hydraulic oil temperature switch (Fig. 10– 60) is

threaded into a welded fitting at the top rear of the

hydraulic oil reservoir, inboard from the hydraulic oil filter

pressure switch. The hydraulic oil temperature switch is

connected to the hydraulic oil filter pressure switch, and

through it to the wiring harness and operators display

panel. When the hydraulic oil temperature is above

195° F (76° C), the hydraulic oil temperature warning

indicator on the operators display panel illuminates. The

vehicle should be stopped and the engine allowed to idle

at high idle for five minutes. If the warning indicator con-

tinues to illuminate after five minutes, the engine must be

shut down to help avoid damage in the hydraulic system.

Examine the fluid in the hydraulic oil sight glass (Fig. 10–

61) to check whether there is a sufficient amount of fluid

in the system (the oil level should be at the bottom of the

sight glass with all hydraulic cylinders retracted) and

whether the fluid is contaminated. Replace the hydraulic

oil filter as required. Explore other causes for excessive

temperature, such as high air temperature, plugged oil

cooler or lines, loose fan belt, plugged radiator, etc.

OS1590

Sight Glass

OS1040

Auxiliary

Function

Manifold

Park Brake

Solenoids

Negative (-)

Terminal