8 electrical system components, Electrical system, 1 warning devices – SkyTrak 3606 Service Manual User Manual

Page 367

Electrical System

10-49

Model 3606 • Origin 10/99

10.8 ELECTRICAL SYSTEM COMPONENTS

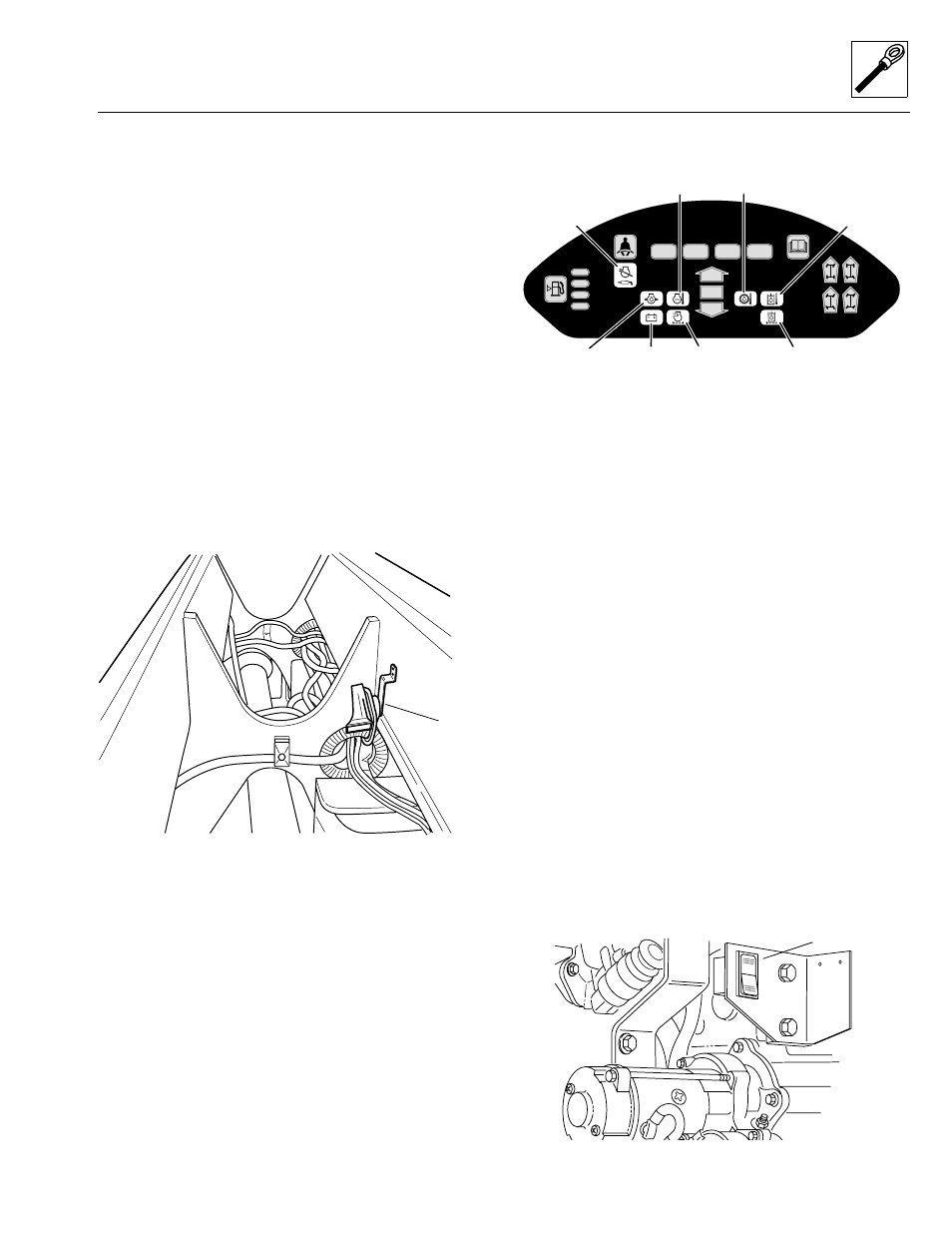

Electrical components include warning devices such as

the indicators in the operators display panel, horn, back-

up alarm, and other components such as the joystick,

logic panel, various solenoids and all accessories.

Examine the appropriate wiring diagrams and

schematics earlier in this section to help understand the

wiring circuits involved.

10.8.1 Warning Devices

Vehicle warning devices include the horn, instrument

panel warning lights, and the back-up alarm.

a. Horn

The horn (Fig. 10– 40) is mounted forward of the cab on

the vehicle frame.

The horn sounds when the momentary-contact horn but-

ton on the center of the steering wheel is pressed.

Removal of the horn button is discussed in Section 4.2.4

Controls of this manual.

Figure 10– 40. Horn location.

The horn sound is produced by a solenoid-actuated dia-

phragm in the horn that develops a resonating air column

in the horn trumpet, which is shaped to project the sound.

If the horn doesn't sound when the horn button is

pressed, check that the fuse is not blown.

Check for corrosion on the horn mounting that may be

preventing a solid ground, and check for a loose horn

wire. Test the horn switch for continuity when the horn

button is pressed.

If the problem is still not located, remove the horn from

the frame and test it using short, heavy-gauge wires con-

nected to a fused or otherwise protected 6-amp minimum

output, 12-volt DC power supply.

b. Warning Indicator Lights

(in operators display panel)

Figure 10– 41. Typical operators display panel

warning indicator lights.

There are eight subdued or "hidden" warning indicator

lights (described below) present in the operators display

panel (Fig. 10– 41). These warning indicators illuminate

during critical circumstances.

IMPORTANT: All eight warning indicator lights demand

immediate attention and vehicle service. In many cases,

the vehicle should be shut down as soon as practical to

help prevent serious mechanical failure. Appropriate ser-

vice procedures for each circuit, as applicable, appear

elsewhere in this section of the manual.

1. Engine Maintenance/Vehicle Lubrication Indicator

This light (item 1, Fig. 10– 41) illuminates every 250 hours

of engine operation to remind the operator that important

maintenance operations are required. After the engine is

serviced (engine oil and engine oil filter changed), the

indicator can be reset by pressing and holding the reset

switch (Fig. 10– 42), then turning the ignition switch to the

RUN position. The indicator light will illuminate during

power-up and will cease to illuminate when it is reset.

The reset switch can then be released. Should there be a

problem with the indicator and it does not cease to illumi-

nate after servicing the engine and conducting the reset

steps above, check the involved circuit and the reset

switch itself for continuity and shorts. Replace a defective

switch. If the problem is determined to exist in the opera-

tors display panel, replace the panel with a new unit.

Figure 10– 42. Typical maintenance reset switch.

MS1830

Horn

1

2

3

4

F

N

R

D

1

2

3

4

5

6

7

8

OS0531

OS0251

Reset Switch