Engine fan belt -28, Lt (see 2.12.8) – SkyTrak 3606 Service Manual User Manual

Page 44

Section 2

2-28

Figure 2–36. Cummins injector and high-pressure

fuel line locations.

4. Tighten the fitting to 22 lb/ft (30 Nm). Repeat this

procedure for each fitting until the engine runs

smoothly. With the engine running, visually check for

leaks. Turn the ignition switch OFF.

2.12.8 Engine Fan Belt

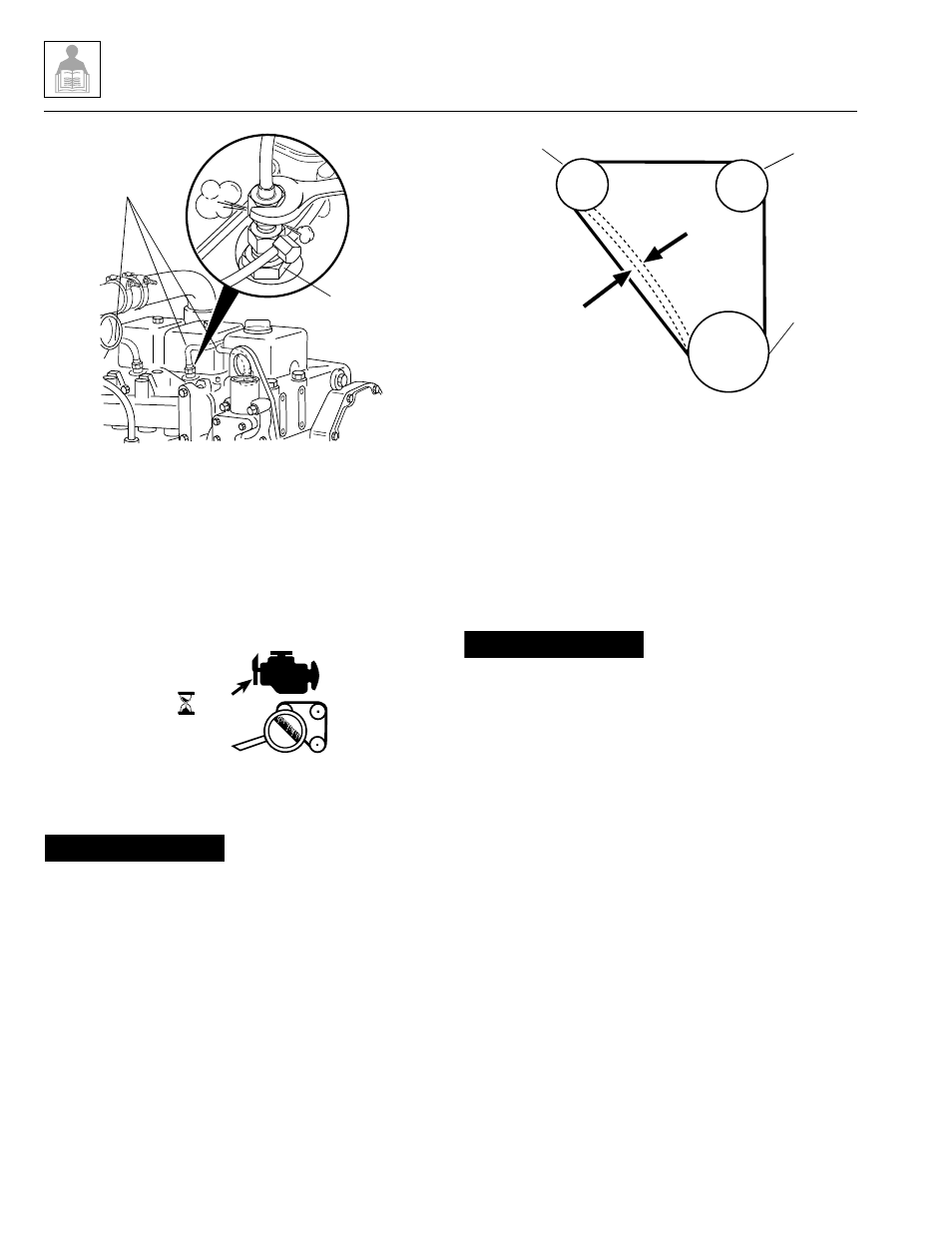

Figure 2–37. Inspect the engine fan belt

every 1,000 hours of engine operation.

1. Ground the attachment, place the travel select lever

in NEUTRAL (N), engage the parking brake switch

and shut off the engine. Allow engine to cool.

2. Unlock and open the engine cover.

3. Inspect the fan belt. Replace if cracked or frayed.

4. Check fan belt tension midway between the crankshaft

and alternator pulleys (Fig. 2–38). Deflection should

be 1/4" to 3/8" (6,4 to 9,4 mm) with an applied force

of 13 to 15 pounds (6 to 7 kg).

Figure 2–38. Perkins engine fan belt adjustment points.

5. If the fan belt needs adjustment, loosen both

alternator mounting bolts and use a fan-belt tensioner

to carefully pry the alternator to tighten the belt. DO

NOT overtighten. Retighten the alternator mounting

bolts.

6. Recheck fan belt deflection. Adjust as necessary.

7. Close and lock the engine compartment cover.

1. Ground the attachment, place the travel select lever

in NEUTRAL (N), engage the parking brake switch

and shut off the engine. Allow engine to cool.

2. Unlock and open the engine cover.

3. The Cummins engine is equipped with an automatic

belt tensioner (Fig. 2–39). Rotate the tensioner up

and remove the fan belt. Inspect the fan belt and

tensioner bearing. Inspect the fan belt. Replace if

cracked or frayed. Spin the bearing, and check for

resistance or rough spots in bearing travel.

4. Spin the fan and check for wobble or excessive play.

Maximum play should be 0.006 inch (0,15 mm).

5. To install the fan belt, position the belt over the

grooved pulleys. While holding the tensioner up, slide

the belt over the water pump pulley.

OS0990

High-pressure

Fuel Lines

Injector

000

1

OS0880

MS2190

PERKINS ENGINE

0A0362

Alternator

Pulley

Fan

Pulley

Crankshaft

Pulley

1/4" to 3/8"

(6,4 to 9,4mm)

Deflection

CUMMINS ENGINE

Model 3606

•

Origin 10/99