Transmission maintenance, Maintenance introduction, Transmission maintenance schedule – SkyTrak 3606 Service Manual User Manual

Page 139

Transmission

7-5

7.4

TRANSMISSION MAINTENANCE

7.4.1 Maintenance Introduction

IMPORTANT: These instructions cover only the routine

maintenance of the transmission. Refer to the Clark-

Hurth T 12000 Powershift Transmission 3, 4, & 6 Speed

Intermediate Drop Maintenance and Service Manual,

part number SM T12-3,4,6 ID for information on trans-

mission diagnosis and internal component replacement.

Cleanliness is of extreme importance. Before attempting

any repairs, thoroughly clean the exterior of the transmis-

sion to help prevent dirt from entering while performing

maintenance checks and procedures.

Section 7.4.2 Transmission Maintenance Schedule pro-

vides a suggested maintenance schedule with refer-

ences to pertinent procedures and instructions in this

manual. To help prevent transmission problems before

they occur, follow the maintenance schedule.

Note: Lubrication and Maintenance Chart decals are

located inside the engine compartment cover (see

Fig. 7–2). These decals contain a general maintenance

schedule that should be followed to maintain the vehicle

in good operating condition (refer to Section 2 General

Information, Specifications and Maintenance Instruc-

tions). The same schedule information is presented in

Section 2.12.10 Transmission Oil and Filter with a

detailed account of how to perform the procedures.

7.4.2 Transmission Maintenance Schedule

Complete transmission maintenance information is

located in Section 2.12.10 Transmission Oil and Filter.

• At ten hour intervals, check the transmission oil level

(see Section 2.12.10 Transmission Oil and Filter).

• When the vehicle completes its first 50 hours of use,

change the transmission filter. Change the filter only;

DO NOT change the transmission oil and the filter at

the first 50 hour maintenance level (see Section

2.12.10 Transmission Oil and Filter).

• At 1,000 hour intervals, change the transmission oil

and filter (see Section 2.12.10 Transmission Oil and

Filter).

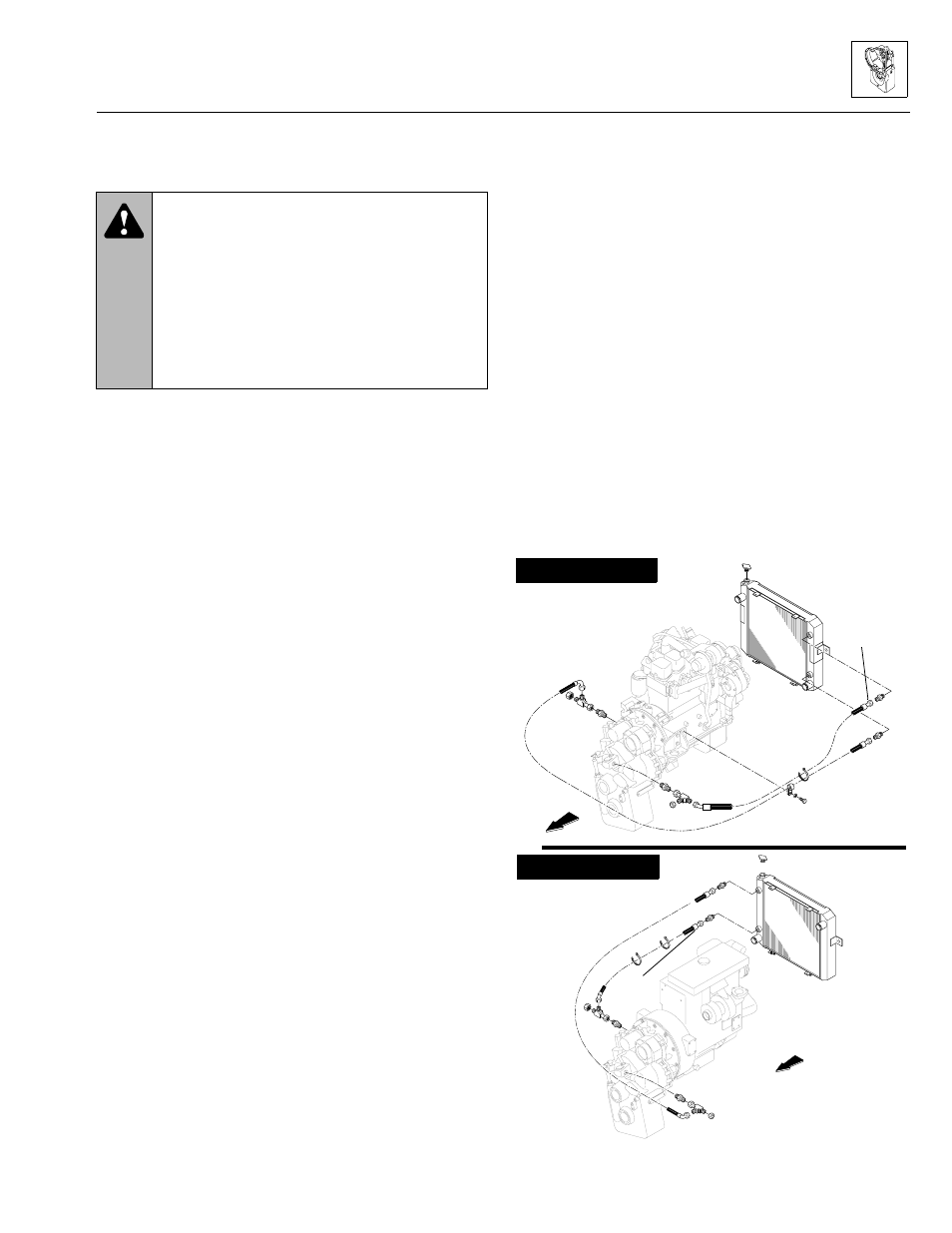

Periodically

Periodically, depending on operating conditions and other

factors, back flush the transmission oil cooler, which is

part of the radiator (Fig. 7–3). ALWAYS back flush the

transmission oil cooler after removing the transmission

for repair or replacement. The transmission oil cooler out-

let hose, routed to the lower radiator fitting, is located on

the right or hydraulic reservoir side of the transmission.

The transmission oil cooler inlet hose, routed to the

upper radiator fitting, is located on the left or boom side

of the transmission, just below the position occupied by

the main hydraulic pump (refer to Section 8A.5.3 Perkins

Engine Radiator and Oil Cooler Replacement, or to Sec-

tion 8B.5.3 Cummins Engine Radiator and Oil Cooler

Replacement for replacement procedures). Disconnect

and back flush the oil cooler portion of the radiator with

oil and compressed air until all foreign material is

removed. If necessary, remove the radiator from the vehi-

cle and clean the oil cooler circuit using oil, compressed

air and steam.

IMPORTANT: DO NOT use flushing compounds for

cleaning purposes.

Figure 7–3. Transmission oil cooler hose routings.

WARNING: To help avoid severe burns, DO

NOT attempt this procedure when the engine,

cooling, and hydraulic systems are hot. Wait

until they have cooled before proceeding.

• Exercise extreme care to help avoid skin

rashes, fire hazards and inhalation of harmful

vapors when using solvent and caustic

cleaners.

• Exercise extreme care when using a steam

cleaner to help avoid burns.

CUMMINS ENGINES

Outlet hose

Outlet

hose

Outlet

hose

Inlet

hose

Inlet

hose

Inlet

hose

Radiator

Radiator

Inlet

hose

PS0740

PS0750

PERKINS ENGINES

Model 3606 • Origin 10/99