Axle service and troubleshooting, Wheels and tires – SkyTrak 3606 Service Manual User Manual

Page 119

Axles, Wheels and Tires

5-9

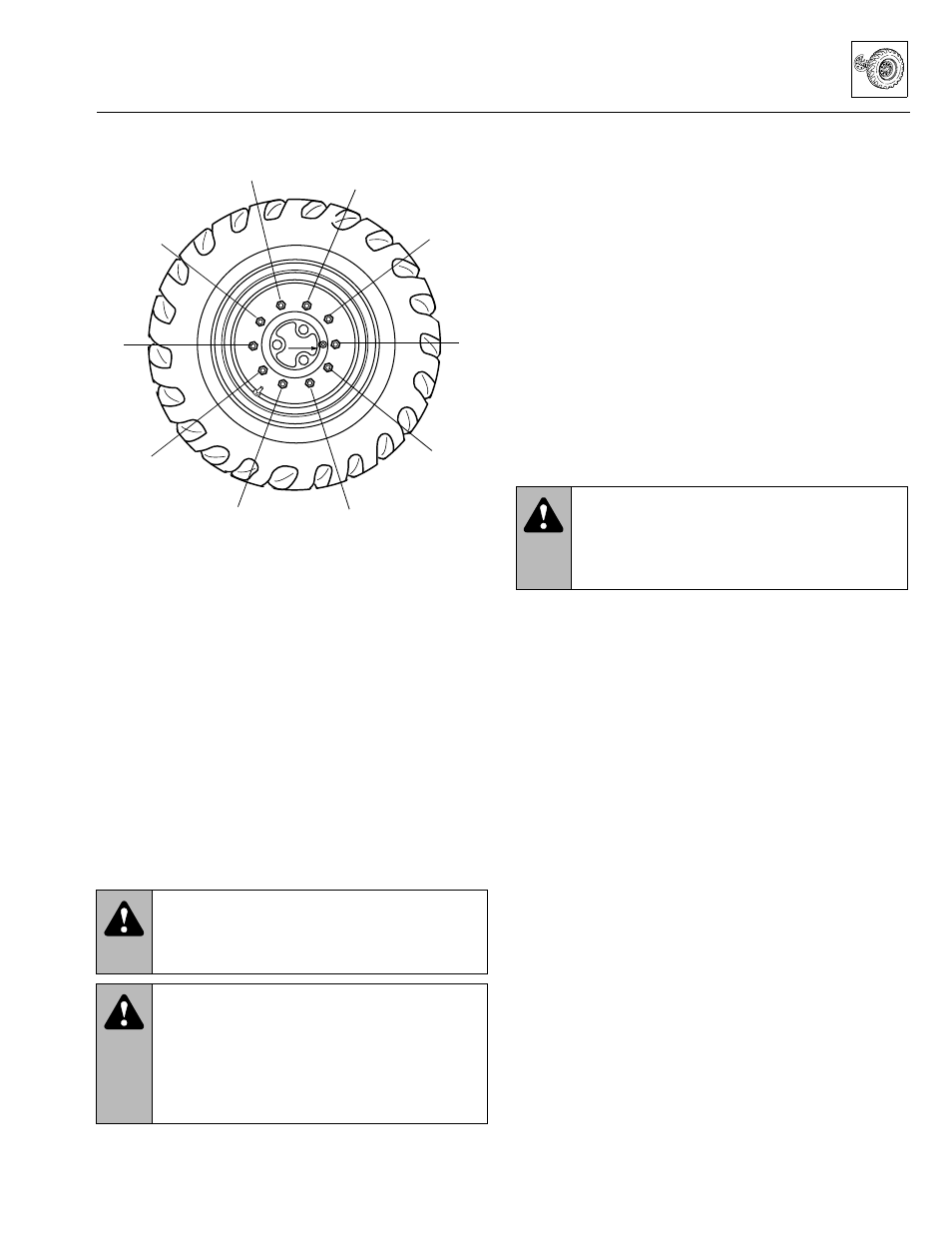

11. Torque the lug nuts to 370 lb/ft (500 Nm) using the

alternating pattern depicted in Fig. 5–5.

Figure 5–5. Lug nut torque sequence.

12. Carefully remove the jack, hoist or overhead crane

and sling supporting the axle.

13. Carefully raise the vehicle using a suitable jack or

hoist. Remove the supports from beneath the frame

and lower the vehicle to the ground.

14. Remove the blocks from the front and rear of both

tires on the other axle.

15. Uncap and connect the steering and brake lines at

their axle fittings.

Note: Always use new flat-faced O-rings when connect-

ing hydraulic fittings on the Model 3606.

16. Check wheel end and hydraulic reservoir oil levels.

17. Reactivate the parking brake on the front axle if it

was deactivated earlier. Refer to Section 2 for

information on parking brake reactivation.

18. Start the engine. Turn the steering wheel several

times lock to lock, operate the frame tilt function

several times in both directions, and check the

function of the brakes. Check for hydraulic leaks and

tighten or repair as necessary.

5.2.2 Axle Service and Troubleshooting

Detailed axle service instructions (covering axle, brakes

and wheel-end safety, repair, disassembly, reassembly,

adjustment and troubleshooting information) are pro-

vided in the Carraro Model 26.25M Maintenance and

Repair Manual, part number CA355027 (limited-slip front

axle with park brake) and CA355028 (rear axle).

The axle should be checked, serviced and repaired only

by experienced service technicians who are aware of all

safety instructions and particular component features.

5.3

WHEELS AND TIRES

Welded 13.00 - 24 steel wheels are used on this vehicle.

The specified size and ply rating (star rating for radial

tires) for this vehicle is 13.00 - 24, 12 PLY. Make sure the

replacement tire is of the same size and ply rating (star

rating for radial tires) as all the other tires. A higher ply

rating (star rating for radial tires) can be used, but only

when all four tires have the same ply rating.

The tires are filled with air only when the vehicle leaves

the factory. Hydrofill (a calcium chloride solution), foam

fill, or other tire-filling substances are not added to the

tires as they alter the weight, stability and handling char-

acteristics of the vehicle, especially under load. Large-

bore valve stems are used to help expedite tire inflation

and deflation. An inner tube may be used if a tire does

not provide an airtight seal. Check tire inflation pressures

when the tires are cold. When mounting a tire on the

wheel, the tire must be mounted on the wheel respective

of the directional tread pattern of the tire; this produces a

left or right tire and wheel assembly.

The wheel and tire assemblies must be installed with the

directional tread pattern “arrows” facing in the direction of

forward travel (Fig. 5–4 and Fig. 5–6).

WARNING: Avoid prolonged engine operation

in closed areas with inadequate ventilation.

Failure to properly ventilate exhaust fumes can

result in death or severe personal injury.

WARNING: Risk of serious personal injury.

Before starting the engine, tighten all hydraulic

connections and remove all tools from the vehi-

cle. NEVER check for leaks using any part of

the human body; use a piece of cardboard or

wood instead. Wear heavy, protective gloves

and eye protection.

OS0740

1

10

5

4

8

2

9

6

3

7

WARNING: Risk of serious personal injury or

death. Mismatched tire sizes, ply ratings or mix-

ing of tire types (radial tires with bias-ply tires)

may compromise vehicle stability and may

result in vehicle tipover.

Model 3606 • Origin 10/99