Fig. 9–60), 2, fig. 9–60) – SkyTrak 3606 Service Manual User Manual

Page 278

Section 9

9-84

When the solenoid is de-energized, the control spool (4)

is returned to its normal condition by the centering

springs (5).

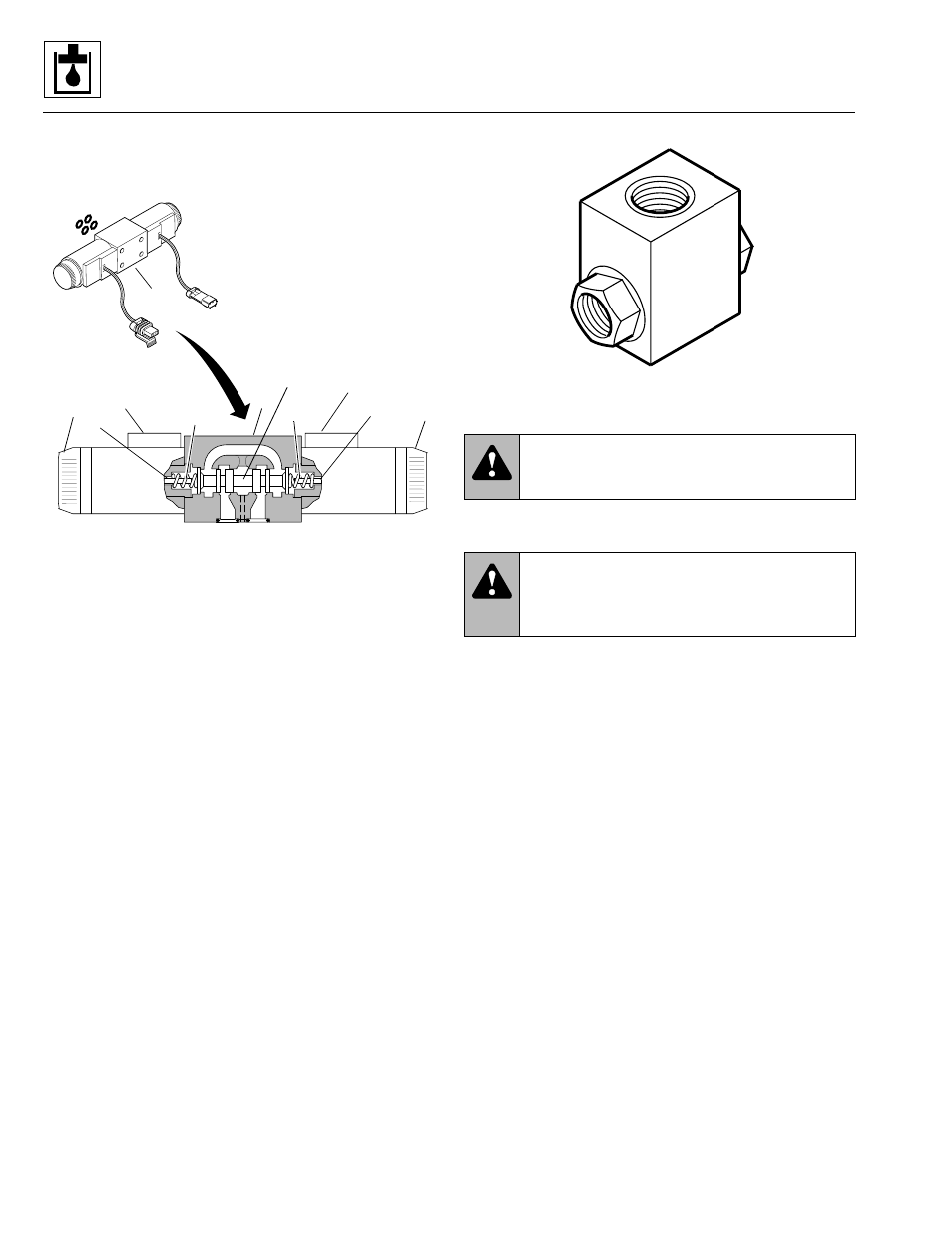

Figure 9– 60. Steer select valve location.

When troubleshooting a steering problem, also check the

steer select valve solenoids for proper operation, and

check the wiring for continuity or shorts.

Refer to Section 10 Electrical System for further informa-

tion on electrical components. Replace a defective or

faulty steer select valve with a new unit.

9.9.8

Shuttle Valve

The shuttle valve (Fig. 9– 61 and Fig. 9– 62) is attached to

the brake valve (Fig. 9– 58) with a 90° elbow fitting. The

shuttle valve joins the steering valve shuttle fluid input

line, shuttle-in line from the main control valve, and the

brake valve load-sense line. The shuttle valve contains a

pressure-dependent two-way check and is a non-service-

able item. It must be replaced in its entirety if defective.

a. Shuttle Valve Removal

1. Park the vehicle on a firm, level surface, fully retract

all hydraulic cylinders, ground the attachment (if any),

place the travel select lever in neutral (N), engage the

park brake switch and shut the engine OFF.

Figure 9– 61. Shuttle valve.

2. Unlatch, unlock and open the engine cover. Allow the

hydraulic fluid to cool.

3. Label or otherwise mark the hydraulic hoses (Fig. 9–

62) at the service brake valve in relation to the shuttle

valve. Disconnect and cap all hoses and fittings, etc.

4. Remove the shuttle valve from the vehicle. Wipe up

any hydraulic fluid spillage in, on, near and around

the vehicle.

b. Shuttle Valve Cleaning, Inspection

and Reassembly

1. Clean the shuttle valve with a suitable cleaner before

inspection.

2. Inspect internal passageways and the shuttle valve

overall for wear, damage, etc. If inner surfaces of the

component do not display an ultra-smooth, polished

finish, or are damaged in any way, replace the shuttle

valve. Most often, dirty hydraulic fluid causes failure

of internal seals and damage to the polished

surfaces within the shuttle valve.

3. Replace a defective shuttle valve with a new one.

Note: Always replace seals, O-rings, gaskets, etc. with

new parts to help ensure proper sealing and operation.

1. O-rings

2. Housing

3. Solenoids (2)

4. Control Spool

5. Return Springs

6. Push Pin

7. Manual Override

8. Solenoid-operated Valve

MS2060

WARNING: Hot hydraulic fluid can cause

severe burns. Wait for hydraulic fluid to cool

before servicing any hydraulic component.

WARNING: Escaping hydraulic fluid under

pressure can penetrate the skin, causing seri-

ous injury. Relieve hydraulic pressure before

servicing any hydraulic component.

P2

P1

P3

MS2080

Model 3606 • Origin 10/99