SkyTrak 3606 Service Manual User Manual

Page 376

Section 10

10-58

Model 3606 • Origin 10/99

a. Fuel Run Solenoid Removal

1. Disconnect the negative (-) battery cable at the

negative battery terminal (Fig. 10– 59).

Figure 10– 59. Disconnect the negative (-) battery cable

at the negative (-) battery terminal.

2. Disconnect the wiring connector at the fuel run

solenoid lead, then remove the fuel run solenoid from

the fuel injector pump.

3. For Perkins engines: Use a wrench to remove the

solenoid.

For Cummins engines: Remove the two bolts

securing the solenoid to the mounting plate. Remove

the nut holding the linkage to the arm on the fuel

injection pump. Save the hardware for later re-use.

b. Fuel Run Solenoid Disassembly

DO NOT disassemble a fuel run solenoid. Replace a

defective fuel run solenoid with a new one.

c. Fuel Run Solenoid Inspection and Replacement

Use a 12-volt DC source and ground to test the solenoid.

Energize the solenoid and watch for the plunger to

retract. If the plunger does not retract, replace the fuel

run solenoid with a new one.

d. Fuel Run Solenoid Installation

1. Clean the exterior of the fuel injector pump.

2. For Perkins engines: Install a new O-ring on the fuel

run solenoid (2, Fig. 10– 57). Install the fuel run

solenoid onto the fuel injector pump (1). Use a

wrench to install the solenoid. DO NOT overtighten.

For Cummins engines: Using the hardware removed

earlier, install the nut holding the linkage to the arm

on the fuel injection pump (2, Fig. 10– 58). Install the

two bolts to secure the solenoid to the mounting

plate.

3. Connect the wiring connector at the fuel run solenoid

lead.

4. Connect the negative (-) battery cable to the negative

battery terminal (Fig. 10– 59).

5. Clear personnel and any obstructions from the area

around the vehicle.

6. Start the engine.

7. If the engine starts, the fuel run solenoid is

functioning.

8. If the engine fails to start, the fuel run solenoid may

have a poor ground connection. Visually check the

wiring at the fuel run solenoid leads and/or check for

continuity with a voltmeter as required.

9. Check for fuel and/or oil leakage around the solenoid.

10.8.6 Hydraulic Oil Filter Pressure Switch

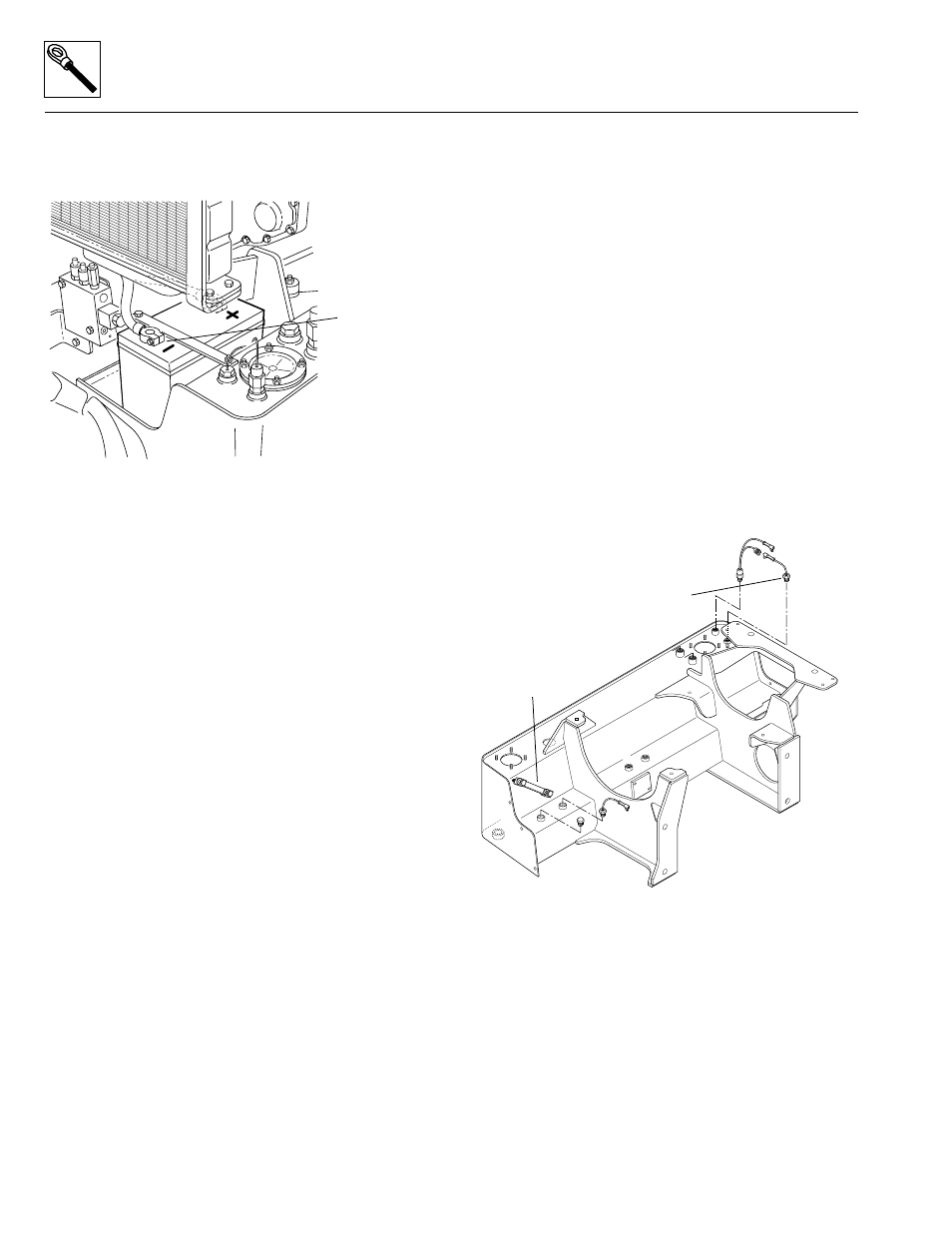

The hydraulic oil filter pressure switch (Fig. 10– 60) is

threaded into a fitting welded at the top rear of the

hydraulic oil reservoir.

Figure 10– 60. Location of the hydraulic oil filter

pressure switch, hydraulic temperature switch,

and hydraulic oil sight glass.

The switch is connected to the wiring harness and to the

hydraulic oil temperature switch. When the 25 psi

(1,7 kPa) hydraulic oil system filter is clogged or

restricted and the internal pressure of the filter rises to 25

psi (1,7 kPa), the switch closes and the hydraulic oil filter

restriction indicator illuminates on the operators display

panel. The vehicle should be stopped and the engine

revved at high idle for five minutes. If the light remains

illuminated or begins to flicker on and off at high idle, shut

down the engine and inspect the hydraulic system.

OS1040

Negative (-)

Terminal

MS1700

Pressure Switch

Temperature Switch

Sight Glass