Piping parameter setting method, Caution, 1) setting method when sensor type is “sx1-a – Dwyer UXF3 User Manual

Page 37: Bulletin f-107-uxf3

-29-

4.6.2. Piping parameter setting method

Description

z Set the parameters of piping and fluid to be measured to determine the sensor mounting spacing.

z The mounting dimension of the sensor is automatically calculated. Refer to “5.1.1. Mounting of detector”.

Be sure to set the following parameters before mounting the sensor on the pipe. Mount the sensor to match the sensor

mounting length.

z Unless the sensor units are spaced accurately, the measurement error will be excessive.

z Also, the received wave may be abnormal.

Setting items

1. Pipe outer diameter

: 6.00 to 6200.00 [mm]; 0.24 to 244 in. (factory set at 60.00 mm/2.36 in.).

2. Piping material

: CARBON STEEL, STAINLESS STEEL, PVC (factory set), COPPER, CAST IRON, ALUMINIUM,

FRP, DUCTILE IRON, PEEK, PVDF, ACRYLIC, PP, Others (Sound velocity: 1000 to 3700[m/s])

3. Wall thickness

: 0.10 to 100.00 [mm] (factory set at 4.00 [mm]).

4. Lining material

: NO LINING (factory set), TAR EPOXY, MORTAR, RUBBER, TEFLON, PYREX GLASS, PVC,

Others (Sound velocity: 1000 to 3700[m/s] or 3281 to 12139 [ft/s])

5. Lining thickness

: 0.10 to 100.00 [mm]; 0.00394 to 3.937 [in.]

6. Measuring fluid

: WATER, SEAWATER, DIST.WATER, AMMONIA, ALCOHOL, BENZENE, ETHANOL, GLYCOL,

KEROSENE, MILK, METHANOL, TOLUOL, LUBE OIL, FUEL OIL, PETROL, REFRIGERANT

R410, Others (Sound velocity: 300 to 2500[m/s]; 984 to 8202 [ft/s] )

7. Dynamic viscosity coefficient : 0.0010 to 999.999 × 10

-6

[m

2

/s]; 0.0108 to 999.999 × 10 [ft /s] (factory set at 10.8 x 10

-6

[ft

2

/s])

8. Detector mounting method : V method (factory set), Z method

9. Detector type

: SX1-A, SX1-B, SX1-C, SX2-A, SX2-B, Reserved

10. Transmission voltage

: 20Vpp, 40Vpp, 80Vpp (factory set), 160Vpp

Normally, select “80Vpp” for the transmission voltage.

For actual keying, refer to the typical operation indicated below. Set the parameter protection to OFF beforehand. (See Section 4.4.1.)

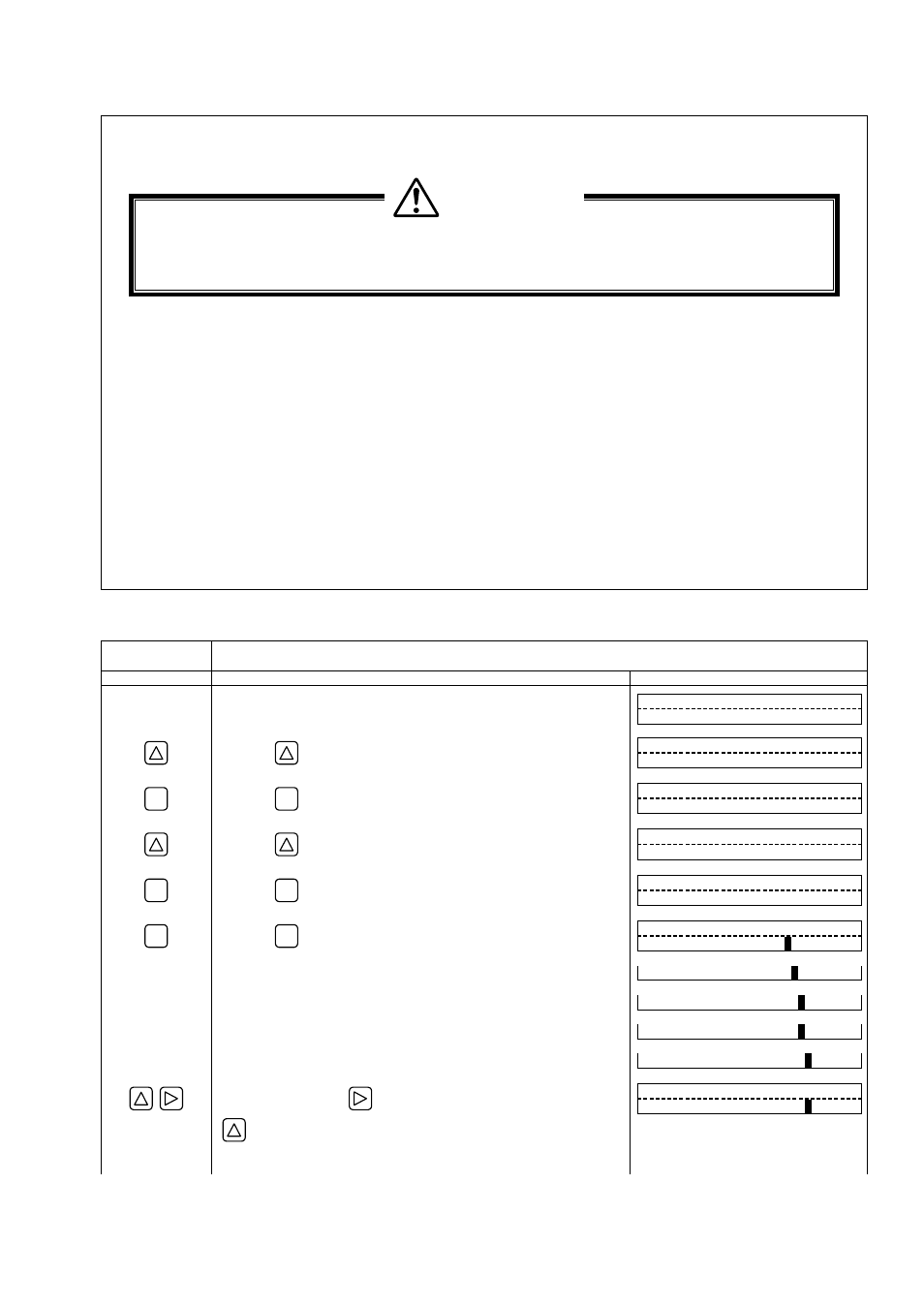

(1) Setting method when sensor type is “SX1-A”.

Operation

(example)

Carry out setting for measuring the flow rate of water flowing through PVC pipe (for tap water).

Key operation

Description

Display

0.000 m/s

0.000 m3/h

ź

Press the

key 3 times to display “MEASURE SETUP”.

MEASURE SETUP

ENT

ź

Press the

ENT

key once to display “SYSTEM UNIT”.

SYSTEM UNIT

METRIC

ź

Press the

key 3 times to display “PROCESS SETTING”.

PROCESS SETTING

S= 16 ( 48mm)

ENT

ź

Press the

ENT

key once to display “OUTER DIAMETER”.

OUTER DIAMETER

60.00 mm

ENT

ź

Press the

ENT

key once to blink the cursor.

OUTER DIAMETER

0

160.00 mm

0

1

60.00 mm

01

6

0.00 mm

01

1

0.00 mm

011

0

.00 mm

ź

Move the cursor by the

key, and change the numeric value by

the key. Operated to compose "114" because, from Piping data in

Section 7.5., the outer diameter of polyvinyl chloride pipe (tap water size)

is 114 mm.

OUTER DIAMETER

11

4

.00 mm

CAUTION

Bulletin F-107-UXF3

2

-6