Error in measured value, Bulletin f-107-uxf3 – Dwyer UXF3 User Manual

Page 124

-116-

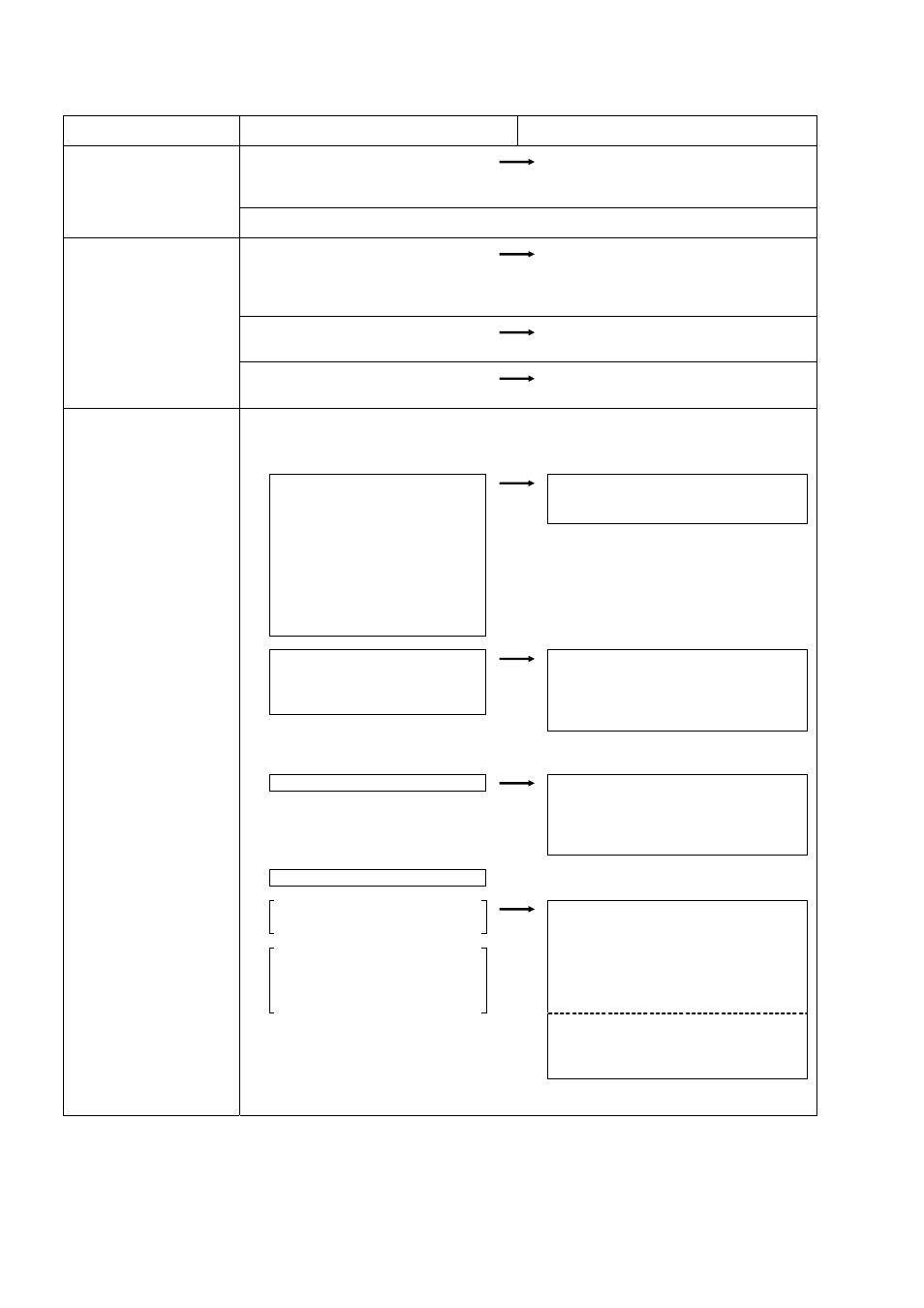

6.6.4. Error in measured value

Status Probable

cause

Troubleshooting

z Connection between main unit and

sensor units (upstream,

downstream) are inverted.

Connect

properly.

The reading appears with

“-” (minus).

z Flow of fluid is reversed.

z Straight pipe length is inadequate.

Move the sensor to the place where the

length of 10D can be assured on

upstream side and 5D on downstream

side.

z Pump, valve or others which

disturb the flow are located nearby.

Mount the instrument with a clearance of

30D or more.

Measured value

fluctuates though flow

rate is constant.

z Pulsation exists in flow.

Set the damping to increase the response

time.

Measured value is held because ultrasonic wave cannot be propagated into a pipe.

1. Incomplete installation

Measured value remains

the same though flow

rate is changing. (LED lit

in red)

z Error in piping specifications

z Sensor is mounted on

welding.

z Error in sensor mounting

dimensions

z Error in silicone appliance at

the time of mounting the

sensor

z Error in connection of the

sensor cable.

Upon checking, remove the sensor,

apply silicone filler, and slightly off

position the sensor.

Sensor mounting is poor

z Mounting dimension

z The sensor is coming off the

pipe.

z Mount the sensor in parallel with

pipe, allowing correct sensor unit

spacing.

z Mount the sensor properly so that it

is kept in close contact with the pipe.

2. Problem on pipe or fluid

{

Pipe not filled with fluid

Locate a place which is completely

filled on the same piping line, and shift

the sensor there.

z Attach the sensor to the lowest place

on the pipeline.

{

Bubbles present in the fluid

Bubbles are introduced if reading

is normal when flow is stopped.

If mounted immediately

downstream a valve, a cavitation

causes the same phenomenon

as when bubbles are introduced.

Eliminate ingress of bubbles.

z Raise the level of the pump well.

z Check the shaft seal of the pump.

z Retighten the flange of negative

pressure pipe.

z Arrange so that fluid doesn’t fall into

the pump well.

Move the sensor to the location where

air bubbles have not entered.

z Inlet side of the pump

z Upstream side of the valve

(Continued on next page.)

Bulletin F-107-UXF3