Outline of installation procedure, Bulletin f-107-uxf3 – Dwyer UXF3 User Manual

Page 15

-7-

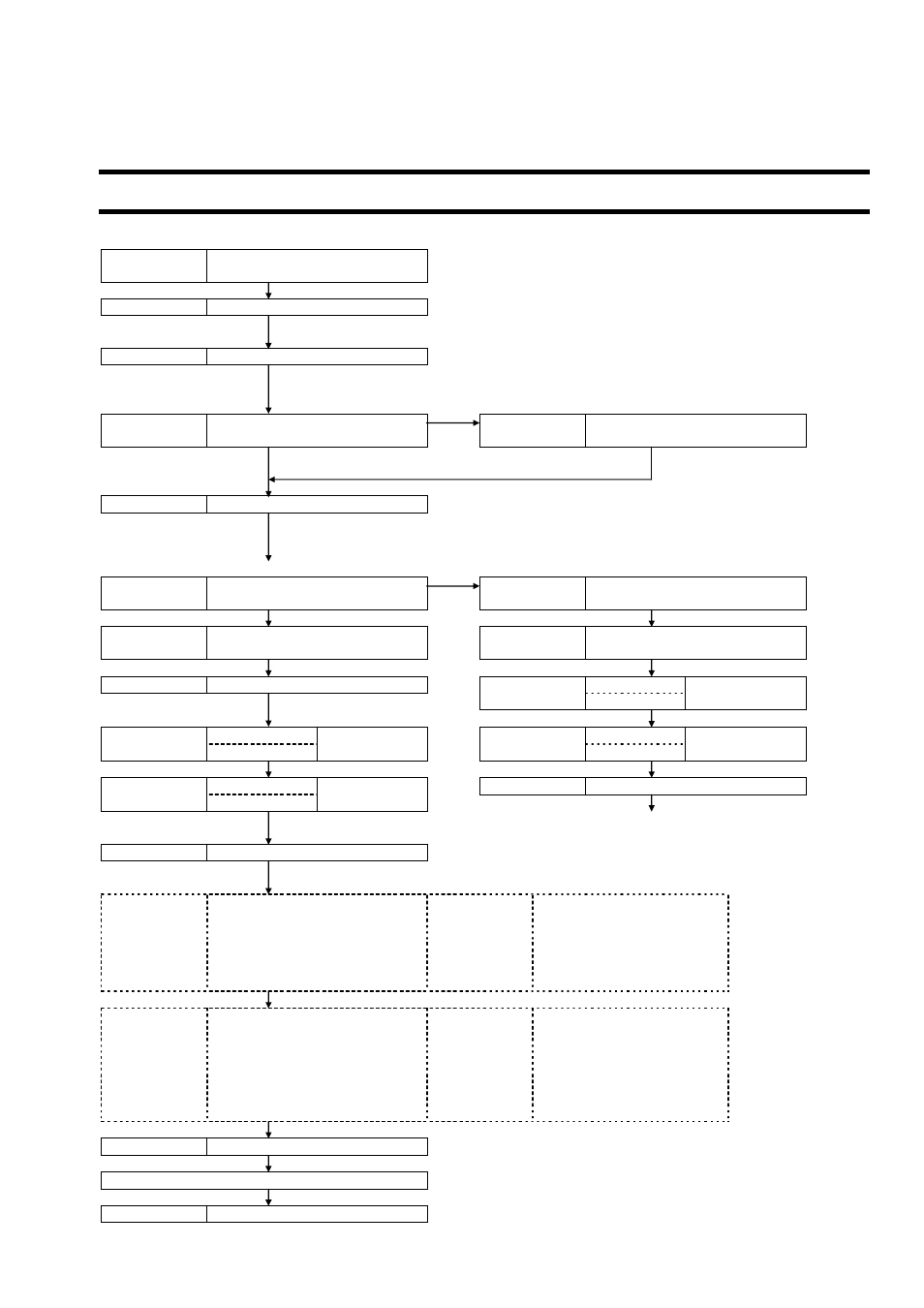

2. INSTALLATION AND BEFORE START OF

OPERATION OF THE FLOW TRANSMITTER

2.1. Outline of installation procedure

Section 3.3

Section 3.4

Installation of flow transmitter

Flow transmitter wiring

Power

ON

*

Check the power supply specifications and wiring before

turning on the power. (Refer to “1.2.Check on type and

specifications”.)

Section 4.4

Parameter protection

* Metric system is selected for unit.

*

The initial display language is English. Switch the languages

as required.

NG

Section 4.6

Checking and Setting of Piping

Specifications/Detector

Section 4.6.2

Piping parameter setting method

OK

Section 5

Mounting of detector

*

Be careful not to mount the sensor units with wrong mounting

dimension. Mount it with the dimension displayed at the

process setting of the piping parameter. (Refer to “5.

Mounting of detector”.)

NG (LED display is red)

Section 6.6.1.3 Checking the RAS information

Section 6.6.2

Displaying the data in

maintenance mode

OK

(LED display is green)

Section 6.6.2

Displaying the data in

maintenance mode

Check the data display

Check the data display

AGC U

AGC

D

35% or more

AGC U

P/H U

AGC

D

35% or more

P/H

D

Outside the range

of 5528 to 6758

P/H U

Section 6.6.6

Checking received waveforms

P/H

D

5528 to 6758

Contact manufacturer's service representative.

Section 4.7

Zero Adjustment

*

Before performing zero point adjustment, check that the pipe

is filled with fluid, the fluid is in still state, and that the

measurement status is normal.

Basic operation

Section 4.9.1.3 Output limit

Section 4.8.1

How to set the unit system

Section 4.9.2

Setting the total

Section 4.9.3

Setting the DO output

Section 4.9.1.1 Setting of flow rate range (single

range)

Section 4.9.3.1 How to validate the total pulse

output

Section 4.9.1.2 Setting of analog output at error

(Burnout)

Section 4.9.4

Setting the LCD indication

Application

operation

Section 4.9.1

Setting of flow rate range

Section 4.10.1 Setting automatic 2 ranges

Section 4.10.5.2 How to validate the alarm

output

Section 4.10.2 Setting the Bi-directional range

Section 4.10.5.3 Setting the flow switch

Section 4.10.3 Setting the Bi-directional auto 2

range

Section 4.10.5.4 How to validate the total

switch

Section 4.10.6

Setting the DI input

Section 7.3

ORDERING INFORMATION

Run

(Measurement)

Section

6 CHECK

AND

MAINTENANCE

Bulletin F-107-UXF3