Assembling procedure of the sensor, Assembly procedure of the sensor, Bulletin f-107-uxf3 – Dwyer UXF3 User Manual

Page 101

-93-

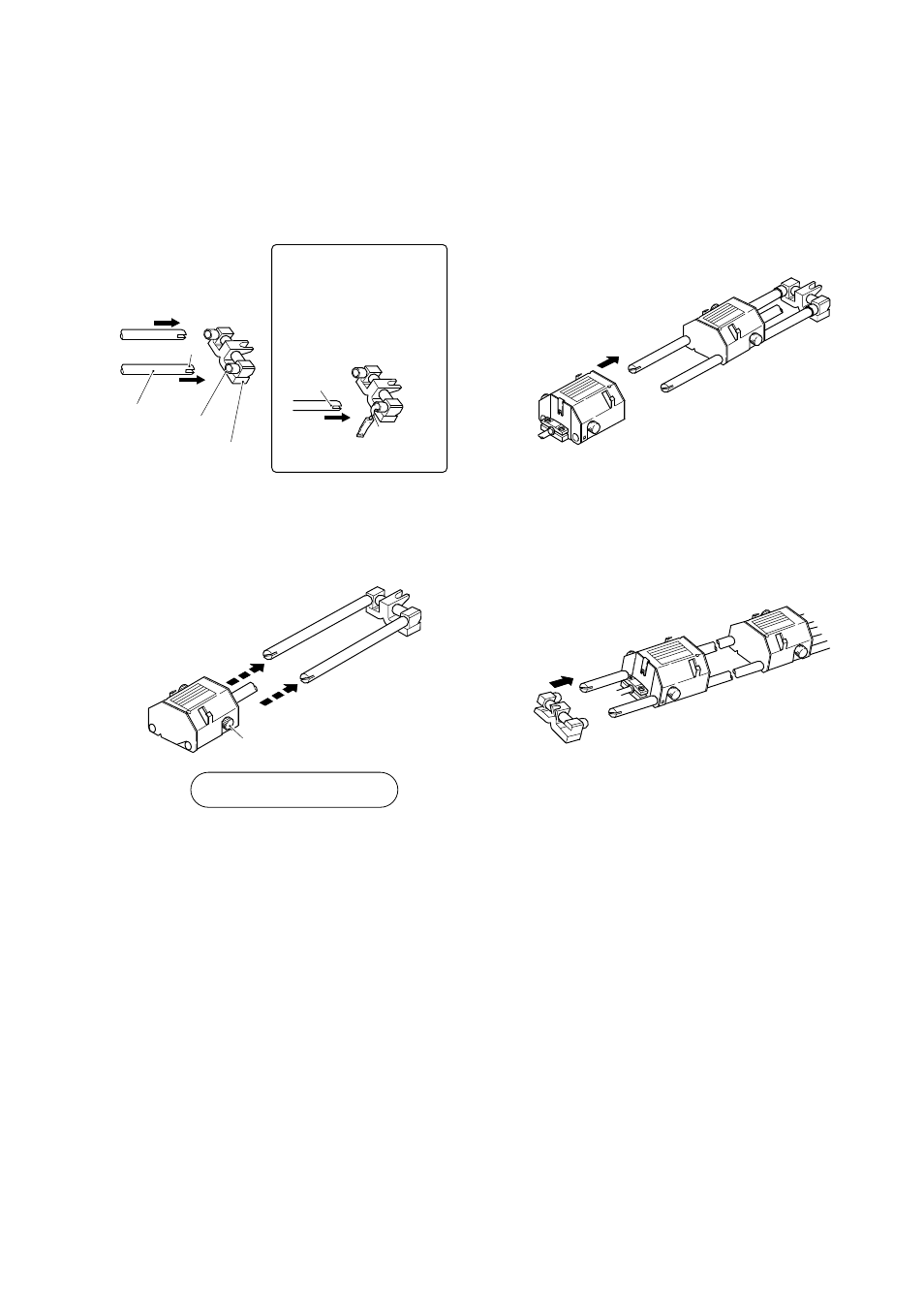

5.9.2. Assembly procedure of the sensor

When the small type sensor (SX1-A) is shipped with cables of more than 10m in length, it is delivered, disassembled since

cable weight is applied to the stand or piping of the sensor during shipment.

Follow the procedure given below.

(1) Be sure to read the “Cautions” before assembling the

parts.

Insert the frame end onto one side of 2 pipes.

Insert

Insert

Silicone

filler

Insert

Pipe

Protrusion

Frame end

Slit

Slit

Apply a coat of silicone to

the frame end.

Take care of the direction

of the frame end and the

slit of pipe.

After inserting the pipes, tap the frame end with a

plastic hammer or the like.

(2) Loosen the retaining knob on the sensor and insert the

pipes.

Retaining knob

Insert it in the correct direction.

(3) Insert another sensor onto the pipes.

Insert it in the correct direction.

(4) Insert the frame end onto the other side of pipes.

Assembling method is the same as (1).

Insert

Note) After assembling the sensor, leave it at room temperature for a day to harden the filler (to obtain the required

assembly strength).

Bulletin F-107-UXF3