Cub Cadet SLTX1000 Series User Manual

Page 86

LTX Tractors

80

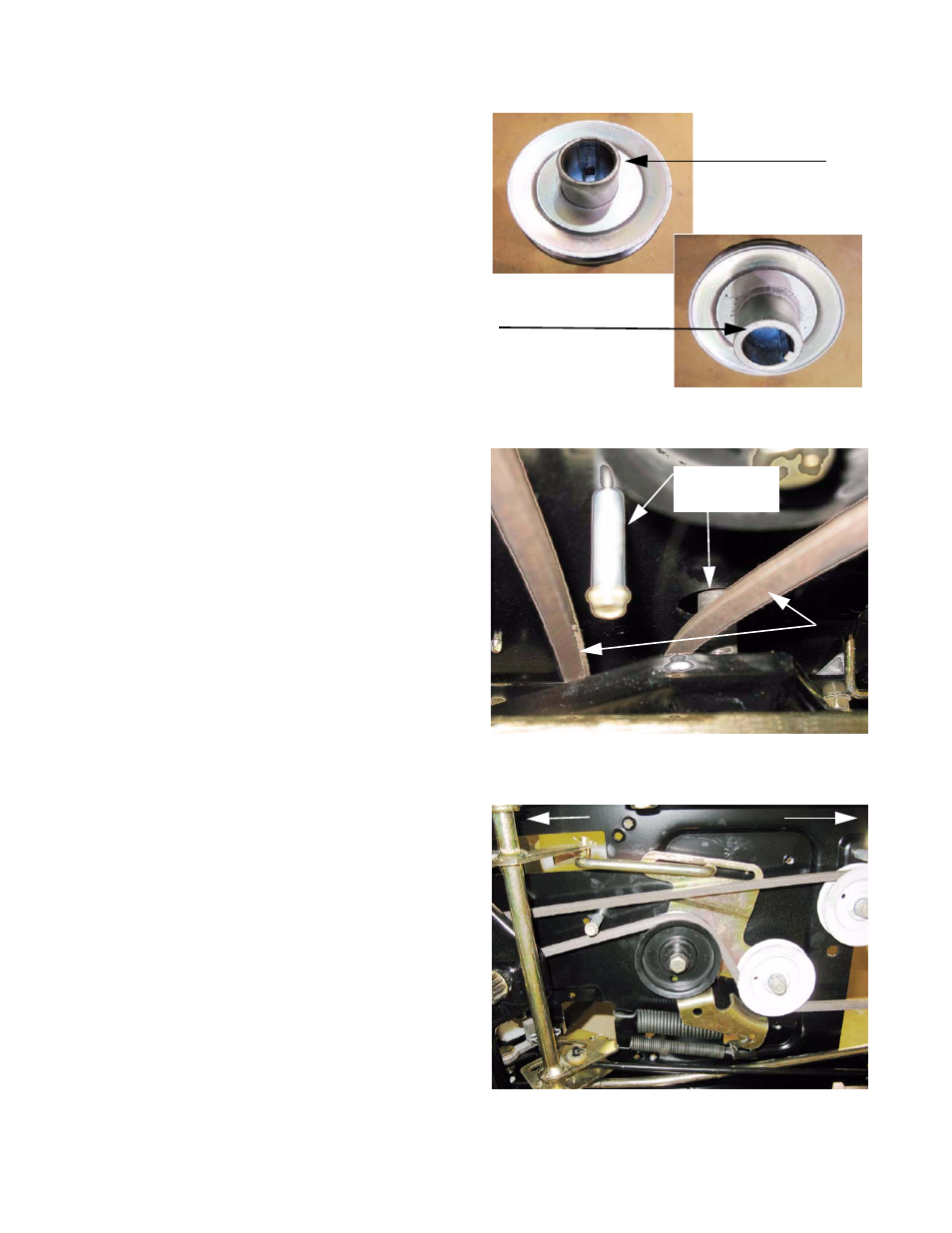

NOTE: The flat edge of the crankshaft pulley faces

the electric PTO clutch. The end with the

inside diameter chamfered goes against the

fillet near the base of the crankshaft.

See Figure 5.58.

11.

If the drive belt failed prematurely, identify and cor-

rect the cause of the failure before installing a new

belt.

12.

Install the new belt by reversing the steps used to

remove it.

Belt installation notes:

•

Install only a correct OEM belt. Incorrect belts

may cause problems that effect the perfor-

mance and/or safety of the tractor.

•

Apply a small amount of anti-seize compound

to the engine crankshaft before installing the

crankshaft pulley.

•

Apply a small amount of thread locking com-

pound such as Loctite 271

TM

(red) to the

threads of the crankshaft bolt.

•

Tighten the bolt to a torque of 36-50 ft-lbs. (50-

68 N-m).

•

The belt is routed to the left of the steering

shaft, and the fore-most keeper pin goes

between the runs of the belt. See Figure 5.59.

•

Correct routing. See Figure 5.60.

•

Tighten the nut that holds the fan and pulley to

the input shaft to a torque of 30-43 ft-lbs (41-58

N-m).

13.

Thoroughly test the operation of the drive system

and all safety features before returning the tractor to

service.

Figure 5.58

Top of

crankshaft pulley

Bottom of

crankshaft pulley

Figure 5.59

Belt keeper pin

Steering shaft

Belt

Looking forward from under the tractor

Figure 5.60

Front Back