Cub Cadet SLTX1000 Series User Manual

Page 139

CVT DRIVE AND BRAKE SYSTEM

133

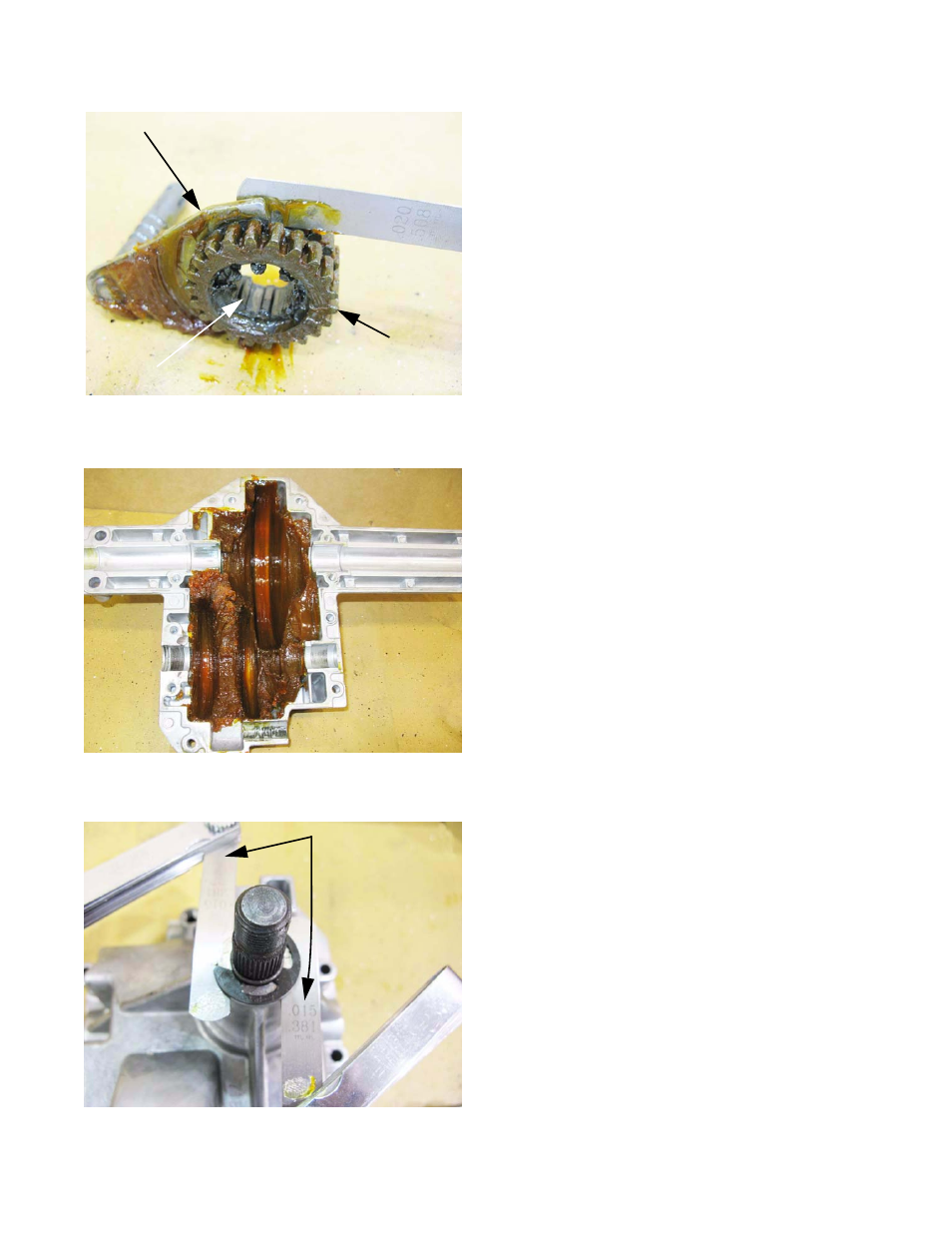

13f. Check the shift collar and fork for wear.

13g. Check shift collar teeth and splines for wear or

damage. See Figure 6.96.

14.

Check the interior of the transaxle housings.

14a. If there is heavy gear-tooth damage on the ring

gear of bevel gears, there is likely to be large

debris in the grease. Dispose of the grease if

the transaxle is to be rebuilt.

14b. If there is heavy wear on any of the contact sur-

faces, there is likely to be small particles of

metal in the grease. Dispose of the grease if the

transaxle is to be rebuilt.

14c. If the grease is obviously contaminated with

water or other substances, dispose of the

grease if the transaxle is to be rebuilt.

14d. If the transaxle is being warranted, leave the

grease and debris in place, after the root cause

of the failure is identified.

14e. If the transaxle is repaired, the damage is iso-

lated, and the grease is not contaminated with

anything, it is acceptable to re-use the grease.

See Figure 6.97.

15.

Inspect the pinion gear and input shaft assembly. See

Figure 6.98.

15a. The pinion gear teeth should not show signs of

heavy wear or damage.

15b. The input shaft should have 0.015”-0.020”

(0.38-0.51mm) end-play, and 0.002”-0.010”

run-out.

Figure 6.96

splines

Shift fork

Teeth

Figure 6.97

Figure 6.98

Feeler gauges