Cub Cadet SLTX1000 Series User Manual

Page 138

LTX Tractors

132

11.

Slip the seals, bearings, and washers off of the dif-

ferential and axle assembly. See Figure 6.94.

NOTE: When correctly installed, the seals fit on the

axle shaft with the lips facing out. Their pri-

mary purpose is to exclude dirt and mois-

ture. Grease does not tend to migrate past

the axle seals.

NOTE: If the transaxle is to be re-built, replace the

bearings and seals with new ones.

12.

Inspect the differential and axle assembly.

12a. Look for damaged ring gear teeth.

12b. With the ring gear held still, turning one axle

should cause the other axle to rotate

smoothly in the opposite direction.

12c. Look for rust or excessive wear on the bearing contact surfaces.

12d. Problems in any of these areas mean the differential assembly should be replaced.

12e. If this is a warranty-related autopsy, identify the root cause of the problem. If it is not something that was

done wrong at the factory, the problem is not warrantable.

NOTE: Cub Cadet does not have a part number for water, and it is not installed at the factory.

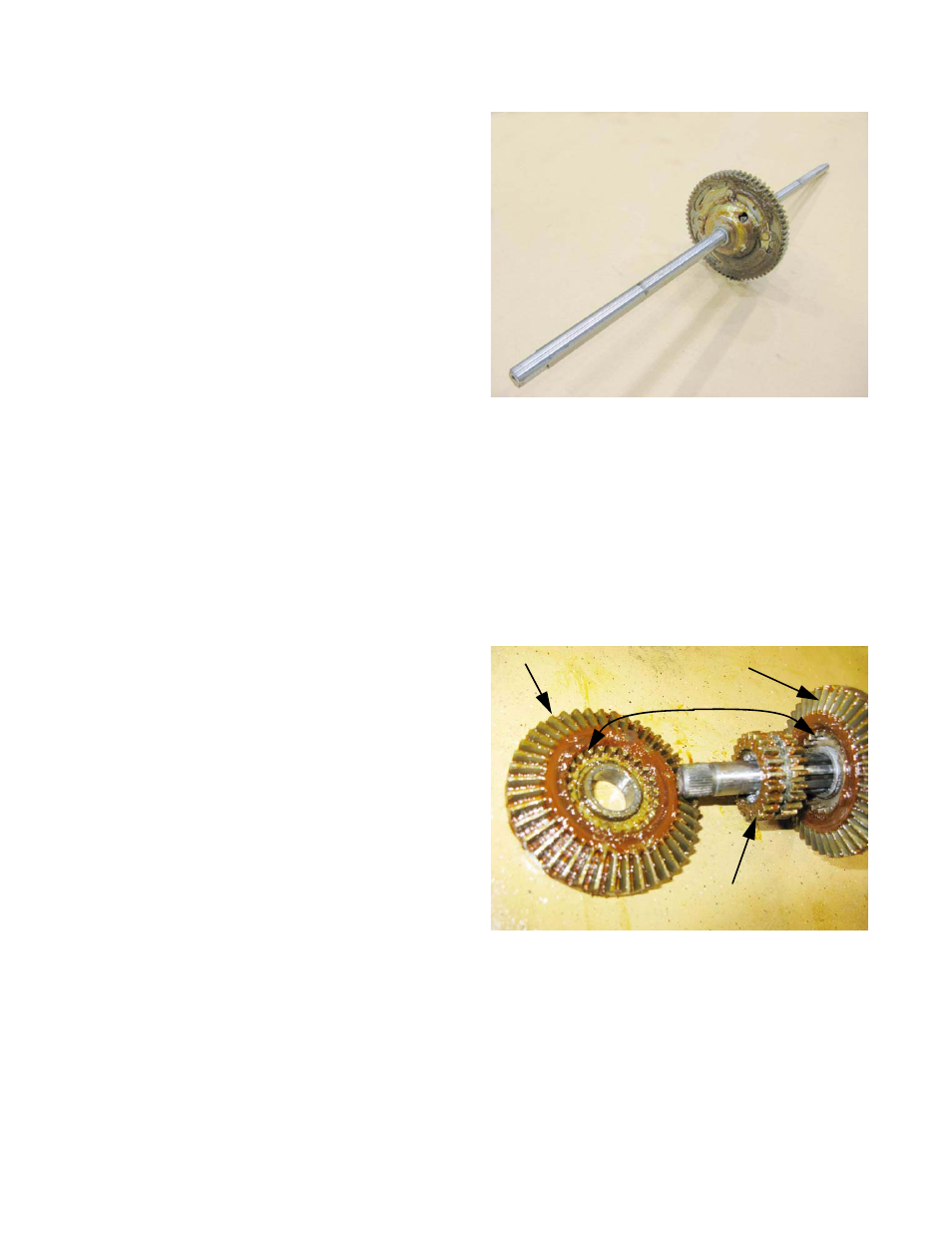

13.

Lift the bevel gears out of the transaxle for disas-

sembly and (mostly) visual inspection.

See Figure 6.95.

13a. Note the placement of the shims on the bevel

gear shaft.

13b. Check the bevel gear teeth (that mesh with

the pinion gear) for wear or damage.

13c. Check the shift collar engagement teeth on

the bevel gears for wear or damage.

13d. Check the inside bearing surface of each

bevel gear for wear or damage.

13e. Check the bevel gear shaft for wear or dam-

age.

Figure 6.94

Differential and axle assembly

Figure 6.95

Forward bevel gear Reverse bevel gear

Engagement teeth

Shift collar