Metrohm 799 GPT Titrino User Manual

Page 72

2.6. Parameters, key

799 GPT Titrino

68

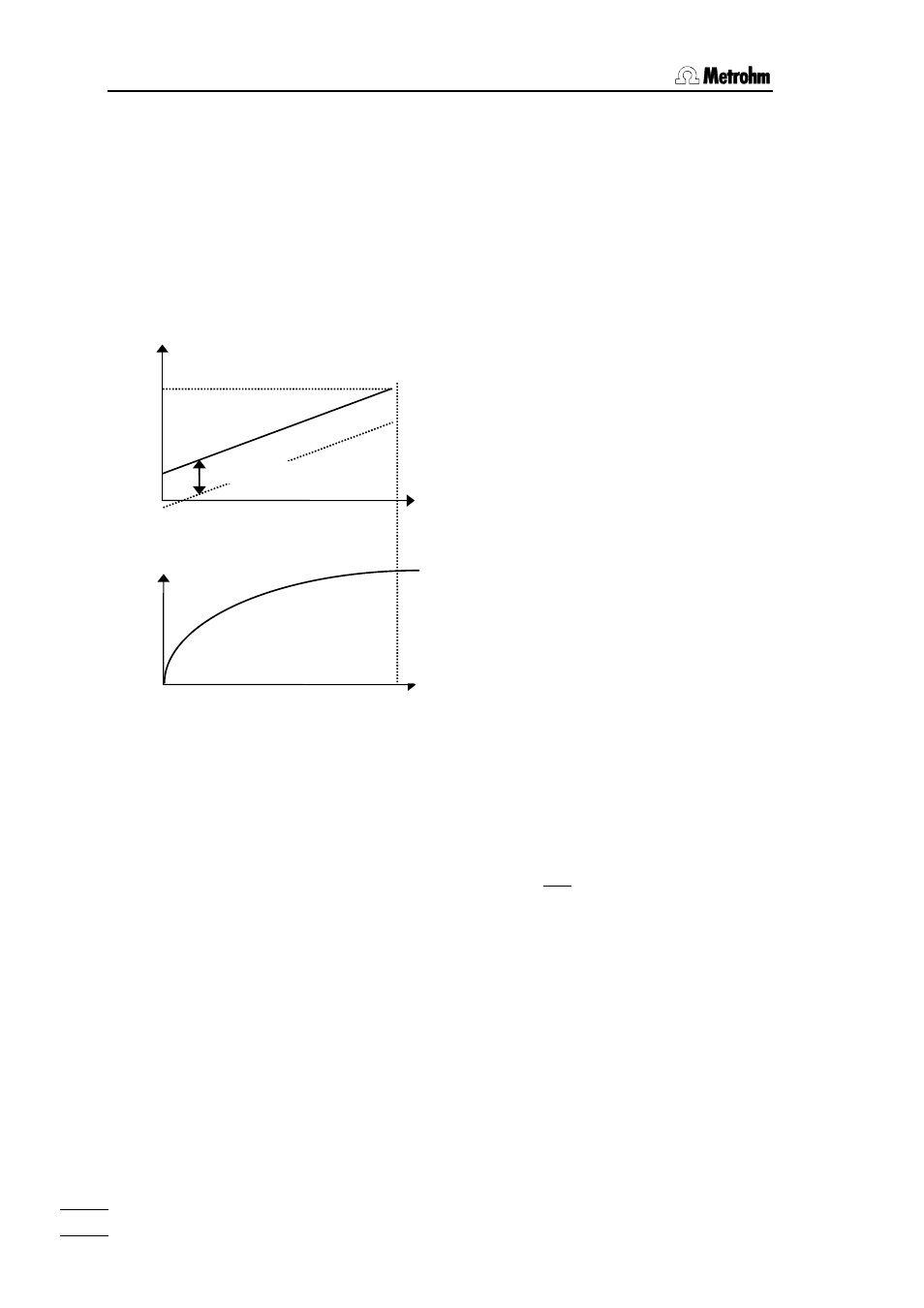

Measured value ramp

In DOC the set value of a measured quantity is changed linearly from a start value to a

final value during a preset sweep time (measured value gradient). The reagent addition is

controlled so that the current measured value follows the nominal value. DOC is stopped

when the sweep time is at an end and (if the measured value monitoring is active) when

the current measured value corresponds to the end of the ramp.

The control deviation nominal-actual value can be kept very small by a suitable choice of

parameters and reagent concentration.

If the current measured values is

still outside of the control range,

the dosing rate is mainly given

by the parameter "max.rate".

If the current measured values is

inside the control range, the

dosing rate is mainly given by

the parameter "min.rate".

If a T sensor is connected, the temperature is measured continuously and pH values

compensated accordingly.

Measuring point list and monitoring

• Measured points are entered in the measuring point list at the preset time interval. The

inputted times represent the clock time. This must be distinguished from the

dispensing time: The dispensing time does not include any wait times which can arise

in refilling, hold or wait as a result of limit value violations.

• If one (or more) entries occur in the time during refilling, one measured point is entered

immediately after the refilling. The time reference otherwise remains unchanged,

however.

• The measuring point list always includes the values "time" and "volume". If monitoring

of measured values and/or temperature is active, the corresponding values are also

entered.

• The "mess." column shows a message if a limit value was violated in the last time

interval, see example of a measured point list on page 53. "*" is also used in this

column to mark when the dispensing was interrupted: refilling, action "wait" or "hold"

on limit value violation or manual

• The volume of the last measured point entry can differ from the final volume as time

may have elapsed between the last entry and the actual stop.

• If the last measured value is important, set the sweep time 1 s higher than the last

expected measured value, i.e. sweep time = (time interval∗number meas.values)+1.

Ende

Start

U/mV

t/s

EP "running"

V/mL

t/s

Control range

Sweep time

Here the final

meas.val. was

reached