This drawing included for reference only – Rockwell Automation 2098-IPD-xxx Ultra5000 Intelligent Positioning Drives Installation Manual User Manual

Page 131

Publication 2098-IN001E-EN-P — April 2002

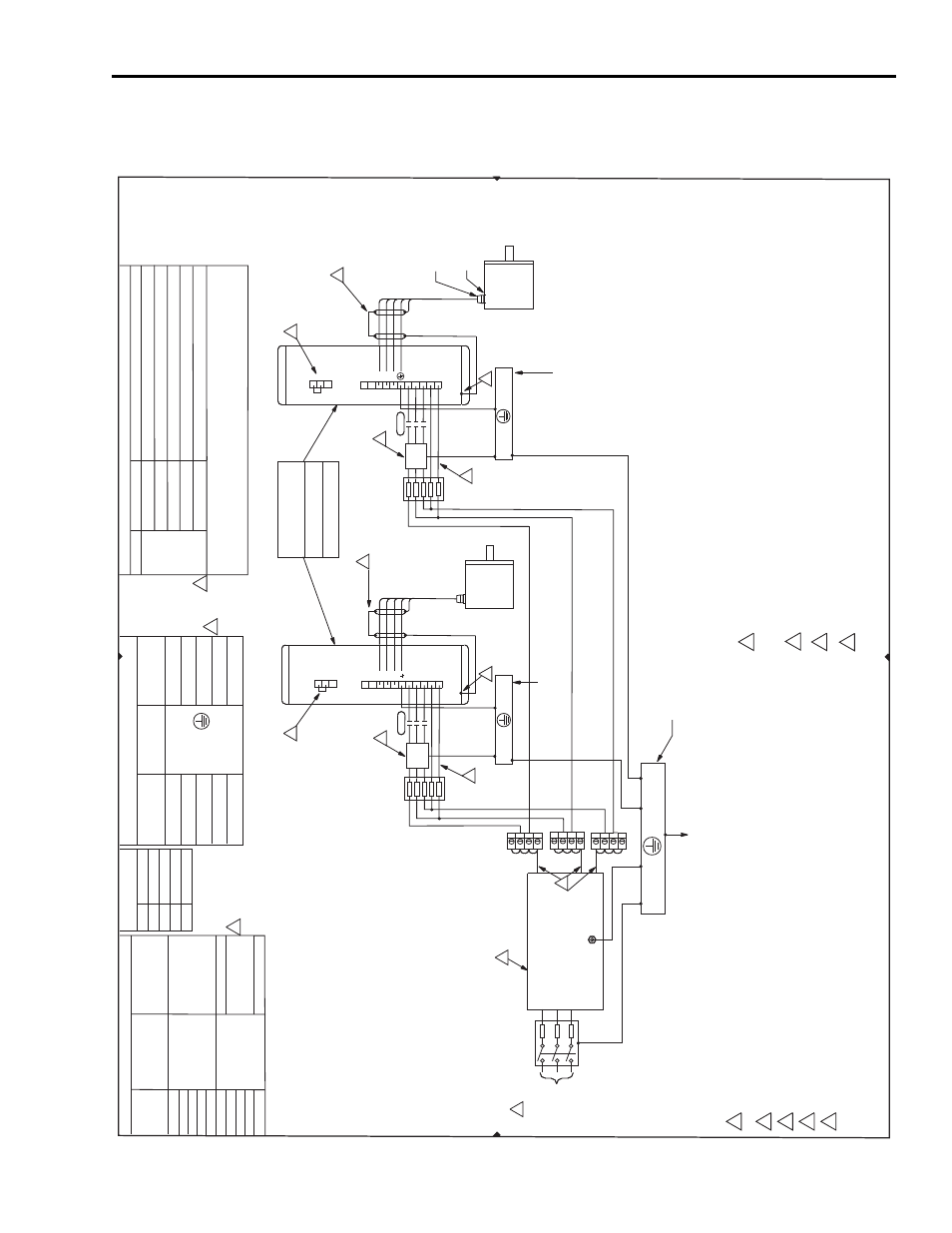

Interconnect Diagrams

B-19

Figure B.18

Typical Power Wiring of Ultra5000 System

2098-IPD-HVxxx-xx

8

8

10

2

MACHINE COMMON

GROUNDING BUS BAR

TO PROTECTIVE

EARTH TERMINAL

ISOLA

TION OR AUTO TRANSFORMER

(OPTIONAL, NOT REQUIRED WHEN

DESIRED INPUT VOL

TAGE IS A

V

AILABLE

DIRECTL

Y FROM THE LINE)

FUSED DISCONNECT

OR CIRCUIT BREAKER

THREE PHASE

AC LINE

50/60Hz

TRANSFORMER

CHASSIS

TERM.

BLOCK

FUSE

BLOCK

M1

MOTOR POWER

CONNECTOR MA

TING

MOTOR POWER

CONNECTOR

9

9

MPL-B3

xx

MPL-B4

xx

MPL-B45

xx

1326AB-B4

xxx

1326AB-B5

xxx

1326AB-B720E

1326AB-B720F

1326AB-B730E

1326AB-B740C

1326AB-B740E

MOTOR POWER

MA

TING CONNECTOR

CONT

ACT SIZE

MOTOR

MINIMUM

RECOMMENDED

POWER WIRE

(75˚C COPPER MIN)

A

B

C

D

PIN

SIGNAL

U

V

W

MOTOR CASE

4

TORQUE ALL TERMINALS

TO 1.25 Nm (11 LB-IN.)

TERMINAL STRIP

ACCEPT

ABLE WIRE RANGE

mm (A

WG)

COMMON GROUNDING

POINT FOR AMPLIFIER

SYSTEM (ONE PER AXIS)

COMMON GROUNDING

POINT FOR AMPLIFIER

SYSTEM (ONE PER AXIS)

mm (A

WG)

mm (A

WG)

RECOMMENDED

POWER WIRE

(75˚C COPPER MIN)

mm (A

WG)

11

8

8

FUSE

BLOCK

M2

3

1

2

3

TB2

10

1

INTELLIGENT

POSITIONING

DRIVE

INTELLIGENT

POSITIONING

DRIVE

AC LINE

FIL

TER

AC LINE

FIL

TER

5

3

2

2

2

2

0.5-6.0mm (22-10 A

WG)

2

DIGIT

AL DRIVE MODULE INPUT CURRENT REQUIREMENTS

INPUT POWER WIRES

MOTOR POWER

CONNECTOR

MOTOR

POWER

WIRES

U,

V

, W

, AND GND

A SUPPL

Y DISCONNECTING DEVICE IS REQUIRED FOR MAINTENANCE & SAFETY

. LOCAL REGULA

TIONS SHOULD BE OBSERVED.

IF A GROUNDED NEUTRAL IS USED INSTEAD OF L2, ONL

Y L1 MA

Y BE SWITCHED OR FUSED.

CURRENT RA

TINGS ARE INDEPENDENT OF THE INPUT VOL

TAGE. REDUCED VOL

TAGE WILL RESUL

T IN A REDUCTION IN SPEED,

BUT NOT TORQUE.

DO NOT DAISY CHAIN DRIVE MODULE POWER CONNECTIONS. MAKE SEP

ARA

TE CONNECTIONS DIRECTL

Y TO THE AC SUPPL

Y.

DRIVE RA

TED 230-480 V

AC RMS, THREE PHASE INPUT VOL

TAGE (480 V

AC ST

ANDARD).

NOTES

2

4

5

6

TERMINA

TE THE MOTOR POWER CABLE SHIELD BY CLAMPING IT TO THE DRIVE WITH THE BRACKET

PROVIDED. THIS BRACKET CAN BE USED FOR STRAIN RELIEF IF NON-SHIELDED CABLES ARE USED.

SNUG BRACKET SCREWS, DO NOT OVER TIGHTEN. NEVER TORQUE OVER 10 LB-IN.

AC LINE FIL

TER AND SHIELDED MOTOR CABLE ARE TO BE USED FOR IMPROVING THE DRIVE MODULES ELECTROMAGNETIC

COMP

A

TIBILITY

, AND ARE REQUIRED TO MEET THE EUROPEAN ELECTROMAGNETIC COMP

A

TIBILITY DIRECTIVE. CAUTION:

AC LINE FIL

TERS HA

VE LARGE LEAKAGE CURRENTS AND REQUIRE DISCHARGE TIME UPON POWER REMOV

AL. WIRING BETWEEN

THE DRIVE MODULE AND FIL

TER SHOULD BE KEPT AS SHORT AS POSSIBLE. THE COMMON GROUND BUS BAR SHOULD BE AS

CLOSE TO THE DRIVE AS POSSIBLE.

WIRE SIZES ARE MINIMUM RECOMMENDED V

ALUES. THE REQUIREMENTS OF LOCAL REGULA

TIONS SHOULD BE OBSERVED.

MUL

TIPLE DRIVE MODULES MA

Y BE POWERED FROM ONE TRANSFORMER OR OTHER AC SUPPL

Y SOURCE.

8

9

10

7

TERMINALS

DRIVE

2098-IPD-HV030

-xx

L1,L2,L3

POWER INITIALIZA

TION REQUIRES A SHORT PERIOD OF INRUSH CURRENT FOR

THE MAIN INPUT AND FOR THE AUXILIARY INPUT

. DUAL ELEMENT TIME DELA

Y

(SLOW BLOW) FUSES ARE RECOMMENDED. FUSE SIZES MUST BE SELECTED

ACCORDING TO LOCAL REGULA

TIONS.

28.0 Amps AC at 230-480 V

olts AC, Three Phase

CURRENT REQUIREMENT

, MAXIMUM (AMPS AC RMS)

TERMINALS

2098-IPD-HV030

-xx

DRIVE

NOTE:

11

IF USING AN AUTOTRANSFORMER, ENSURE THE PHASE TO NEUTRAL/GROUND VOL

TAGE DOES NOT EXCEED THE INPUT

RA

TINGS OF THE DRIVE.

L1/2 AUX MA

Y BE USED TO KEEP LOGIC SECTION OF DRIVE MODULE SUPPLIES POWERED AFTER MAIN AC SUPPL

Y IS TURNED OFF A

T

L1, L2, L3 TERMINALS (EXAMPLE: TO RET

AIN DIAGNOSTIC ST

A

TUS OF DRIVE MODULE AFTER L1, L2, L3 POWER DOWN). SEP

ARA

TE

SUPPL

Y PHASES MA

Y BE USED WHEN VOL

TAGE BETWEEN ANY TWO TERMINALS DOES NOT EXCEED 528V AC RMS.

1

3

JUMPER INST

ALLED A

T F

ACTORY FOR INTERNAL SHUNT

.

L1, L2, L3

2

4.0 mm (12 A

WG)

2

1.5 mm (16 A

WG)

2

10 mm (8 A

WG)

1

2098-IPD-HV050

x-xx

2098-IPD-HV100

-xx

2098-IPD-HV150

-xx

2098-IPD-HV220

-xx

2.5 mm (14 A

WG)

2

2.5 mm (14 A

WG)

2

4.0 mm (12 A

WG)

2

6.0 mm (10 A

WG)

2

10 mm (8 A

WG)

2

2098-IPD-HV050

-xx

2098-IPD-HV100

-xx

2098-IPD-HV150

-xx

2098-IPD-HV220

-xx

4.0 Amps AC at 230-480 V

olts AC, Three Phase

7.0 Amps AC at 230-480 V

olts AC, Three Phase

14.0 Amps AC at 230-480 V

olts AC, Three Phase

20.0 Amps AC at 230-480 V

olts AC, Three Phase

TB1

DC+

DC-

W

V

U

L3

L2

L1

L1 Aux

L2 Aux

TB1

DC+

DC-

W

V

U

L3

L2

L1

L1 Aux

L2 Aux

2

4.0 mm (12 A

WG)

2

6.0 mm (10 A

WG)

2

10 mm (8 A

WG)

COMP

A

TIBLE

MOT

ORS

COMP

A

TIBLE

MOT

ORS

1

2

3

TB2

This drawing included

for reference only.