4 sensor selection guide – INFICON XTC/C Thin Film Deposition Controller User Manual

Page 70

3 - 6

IP

N 07

4-

18

3X

XTC/C - XTC/2 Operating Manual

3.4 Sensor Selection Guide

The choice of sensor type must be dictated by the process, the deposition

material and the physical characteristics of the process chamber. General

guidelines for each sensor type produced by INFICON are outlined in the

Sensor Selection table below. For specific recommendations, consult your

INFICON representative.

*These temperatures are conservative maximum device temperatures, limited by the

properties of Teflon at higher temperatures. In usage, the water cooling allows

operation in environments that are significantly elevated, without deleterious effects.

NOTE: Do not allow water tubes to freeze. This may happen if the tubes pass through

a cryogenic shroud and the water flow is interrupted.

NOTE: For best operation, limit the maximum input water temperature to

less than 30 °C.

NOTE: In high temperature environments more heat may transfer to the water through

the water tubes than through the actual transducer. In extreme cases it may be

advantageous to use a radiation shield over the water tubes.

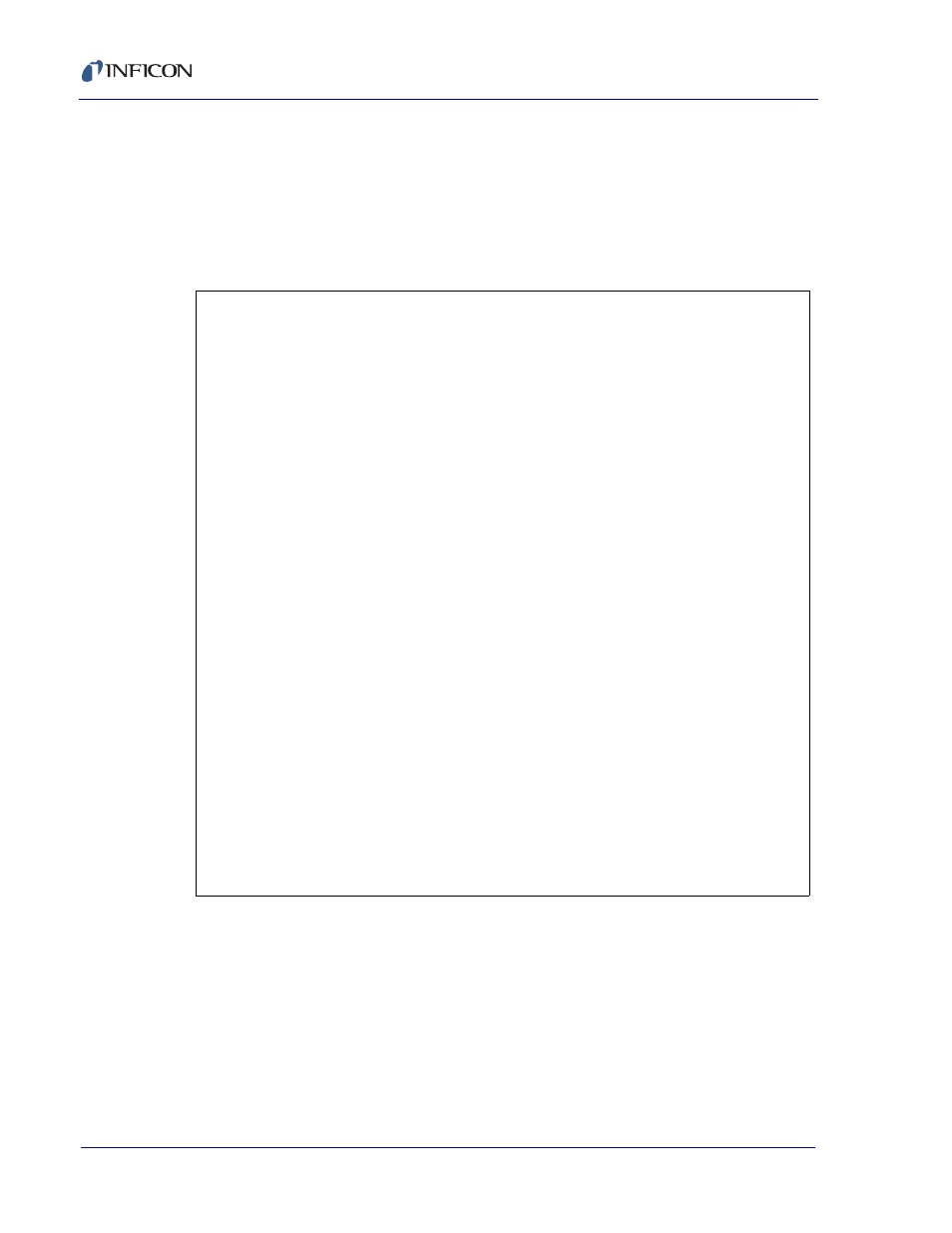

Table 3-1 Sensor Selection Table

Name

IPN

Temp

°C

Crystal

Exchange

Utility

Connector

Comments

Standard

750-211-G1

130°

Front

Side

Standard

w/Shutter

750-211-G2

130°

Front

Side

Compact

750-213-G1

130°

Front

Rear

For tight spaces

Compact

W/Shutter

750-213-G2

130°

Front

Rear

For tight spaces

Dual

750-212-G2

130°

Front

Side

Two crystals for

crystal switch.

Includes Shutter

Sputtering

007-031

130°

Rear

Side

For RF and diode

sputtering. (Optional

shutter available.)

Bakeable

12" (304.8 mm)

20" (508 mm)

30" (762 mm)

007-219

007-220

007-221

450°

Front

Side

Must remove water

cooling and open the

tubes prior to

bakeout

Bakeable

w/Shutter

12" (304.8 mm)

20" (508 mm)

30" (762 mm)

750-012-G1

750-012-G2

750-012-G3

450°

Front

Side

Must remove water

cooling and open the

tubes prior to

bakeout

CrystalSix

750-446-G1

130°

Front

Side

6 crystals for process

security.