3 period measurement technique – INFICON XTC/C Thin Film Deposition Controller User Manual

Page 139

5 - 7

IP

N 07

4-

18

3X

XTC/C - XTC/2 Operating Manual

induced stresses, it is essential to minimize these temperature-induced

changes. It is only in this way that small changes in mass can be measured

accurately.

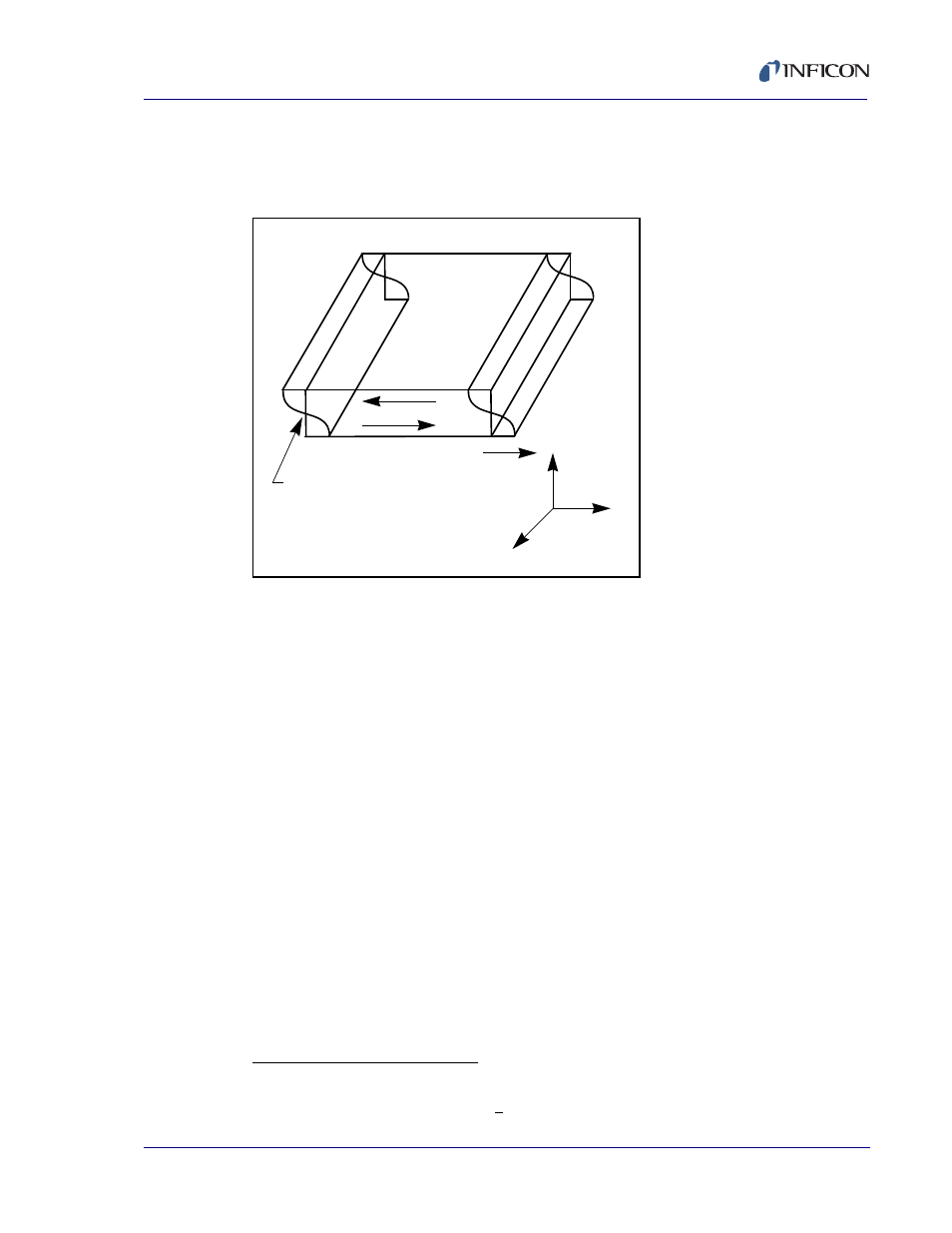

Figure 5-3 Thickness Shear Displacement

5.5.3 Period Measurement Technique

Although instruments using

equation [6]

were very useful, it was soon noted

they had a very limited range of accuracy, typically holding accuracy for

∆F less

than 0.02 F

q

. In 1961 it was recognized by Behrndt

4

that:

[7]

where T

c

and Tq

are the periods of oscillation of the crystal with film and the

bare crystal respectively. The period measurement technique was the

outgrowth of two factors; first, the digital implementation of time measurement,

and second, the recognition of the mathematically rigorous formulation of the

proportionality between the crystal’s thickness, I

q

, and the period of oscillation,

T

q

= 1/F

q

. Electronically the period measurement technique uses a second

crystal oscillator, or reference oscillator, not affected by the deposition and

usually much higher in frequency than the monitor crystal. This reference

oscillator is used to generate small precision time intervals which are used to

determine the oscillation period of the monitor crystal. This is done by using two

pulse accumulators. The first is used to accumulate a fixed number of cycles,

m, of the monitor crystal. The second is turned on at the same time and

displacement node

X

X

X

2

1

3

E

4.K. H. Behrndt, J. Vac. Sci. Technol. 8, 622 (1961)

M

f

M

q

-------

T

c

T

q

–

(

)

T

q

-----------------------

F

∆

(

)

F

c

------------

=

=