INFICON XTC/C Thin Film Deposition Controller User Manual

Page 157

6 - 9

IP

N 07

4-

18

3X

XTC/C - XTC/2 Operating Manual

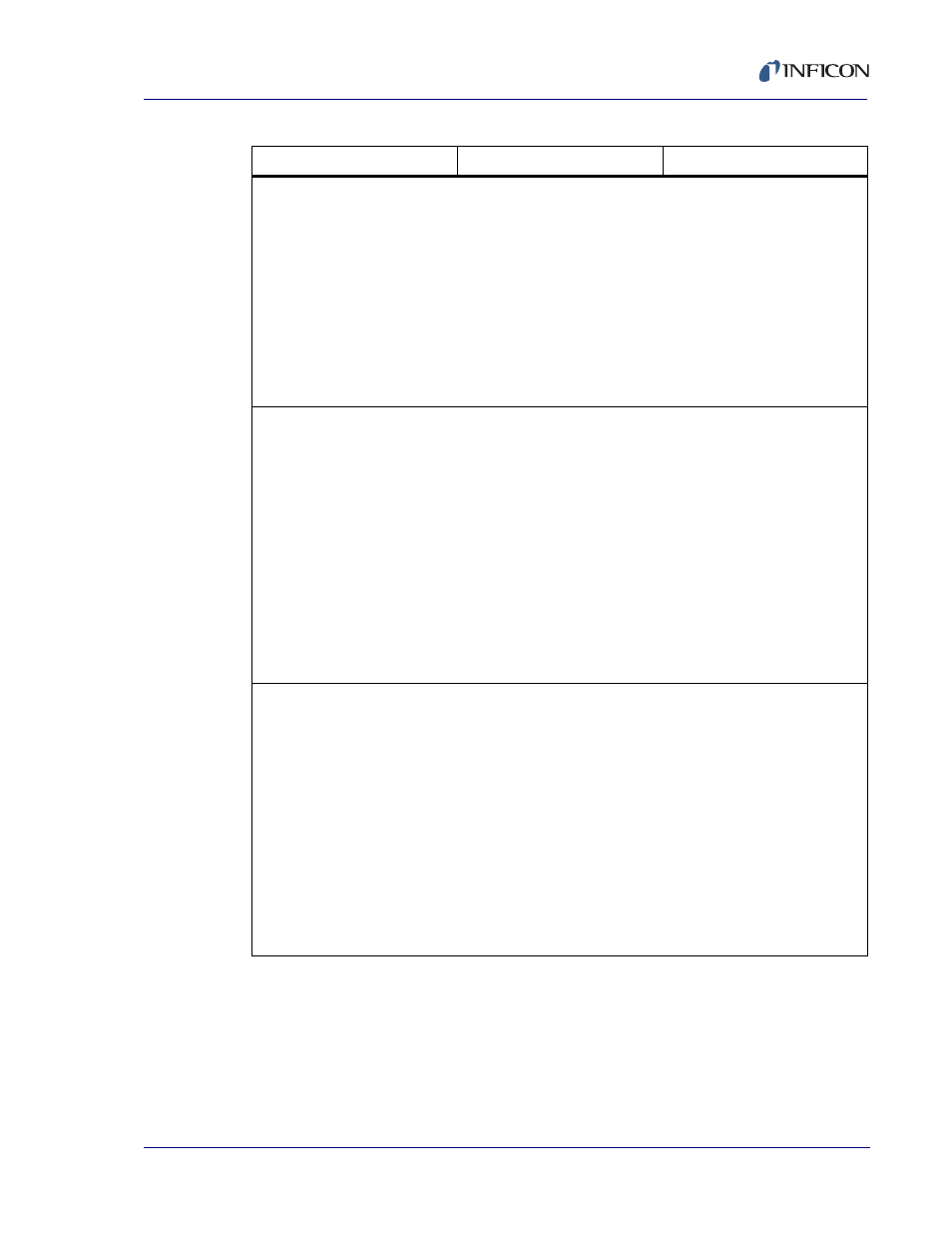

c. material does not adhere to

crystal

c. make certain the crystal’s

surface is clean; avoid

touching crystal with fingers,

make use of an intermediate

adhesion layer

d. cyclic change in rate

d. make certain source’s

sweep frequency is not

"beating" with the

measurement frequency

[nearly the same frequency or

a near multiple of the

measurement (4 Hz)]

7. large drift in thickness

(greater than 200 Å for a

density of 5.00 g/cc) after

termination of sputtering

a. crystal heating due to poor

thermal contact

a. clean or polish the crystal

seating surface on the crystal

holder

b. external magnetic field

interfering with the sensors

magnetic field (sputtering

sensor)

b. rotate sensor magnet to

proper orientation with

external magnetic field, refer

to sputtering sensor manual

IPN 074-157

c. sensor magnet cracked or

demagnetized (sputtering

sensor)

c. check sensor magnetic field

strength, the maximum field at

the center of the aperture

should be 700 gauss or

greater

8. CrystalSix, crystal switch

problem (does not advance or

not centered in aperture)

a. loss of pneumatic supply, or

pressure is insufficient for

proper operation

a. ensure air supply is

regulated at 80-90 PSI

b. operation has been

impaired as a result of

material accumulation on

cover

b. clean material

accumulation as needed,

refer to CrystalSix manual IPN

074-155 for maintenance

c. improper alignment

c. realign as per instructions in

CrystalSix manual IPN

074-155

d. 0.0225" diameter orifice not

installed on the supply side of

solenoid valve assembly

d. install orifice as shown in

the CrystalSix manual IPN

074-155

Table 6-2 Troubleshooting Transducers/Sensors (continued)

SYMPTOM

CAUSE

REMEDY