INFICON XTC/C Thin Film Deposition Controller User Manual

Page 122

4 - 18

IP

N 07

4-

18

3X

XTC/C - XTC/2 Operating Manual

accumulator does not retain its values, but rather, builds up when the rate

deviation exceeds its set tolerance and counts down to zero when the rate

deviation is within its programmed tolerance band.

The S accumulator shows the total magnitude of only the positive frequency

shifts (in Hz) from the moment the start button is pushed until that film is

completed and the next film layer is started. When the S value exceeds the set

point, the crystal is disabled. Unlike the Q accumulator, the S values are

retained and added to the accumulator whenever the positive frequency shift is

greater than 25 Hz. Table 4.4 shows the accumulated frequency shift required

to trigger the switch.

One problem is E-B gun arcing. If the S value constantly increments during arcs

it usually indicates poor grounding and the S factor should be disabled until this

problem is corrected.

Improved rate and thickness information results from programming non-zero

values for Q and S. The trade off is between improved process control and

lower crystal utilization. By observing the behavior on the operating display a

determination can be made, after several runs, whether or not the programmed

values provide a desirable compromise.

INFICON’s laboratory experiments have shown the following values to be

useful and they can serve as general guidelines.

If the process/crystal behavior is unknown and you want to employ the Q and

S factors, start with S = Q = 5 and watch their behavior on the display by

pressing the LIFE switch. Monitor and fine tune these parameters until the

desired level of rate control is ensured.

Often during process setup, the initial settings of the Q factor may soft fail the

crystal sensor. This can be caused by process delays in getting the system

under control (i.e., slow response sources or SOAK2 power levels poorly set).

The crystal sensor’s state of soft failure can be cleared or reset by changing or

re-entering the value of the Q or S factor parameter.

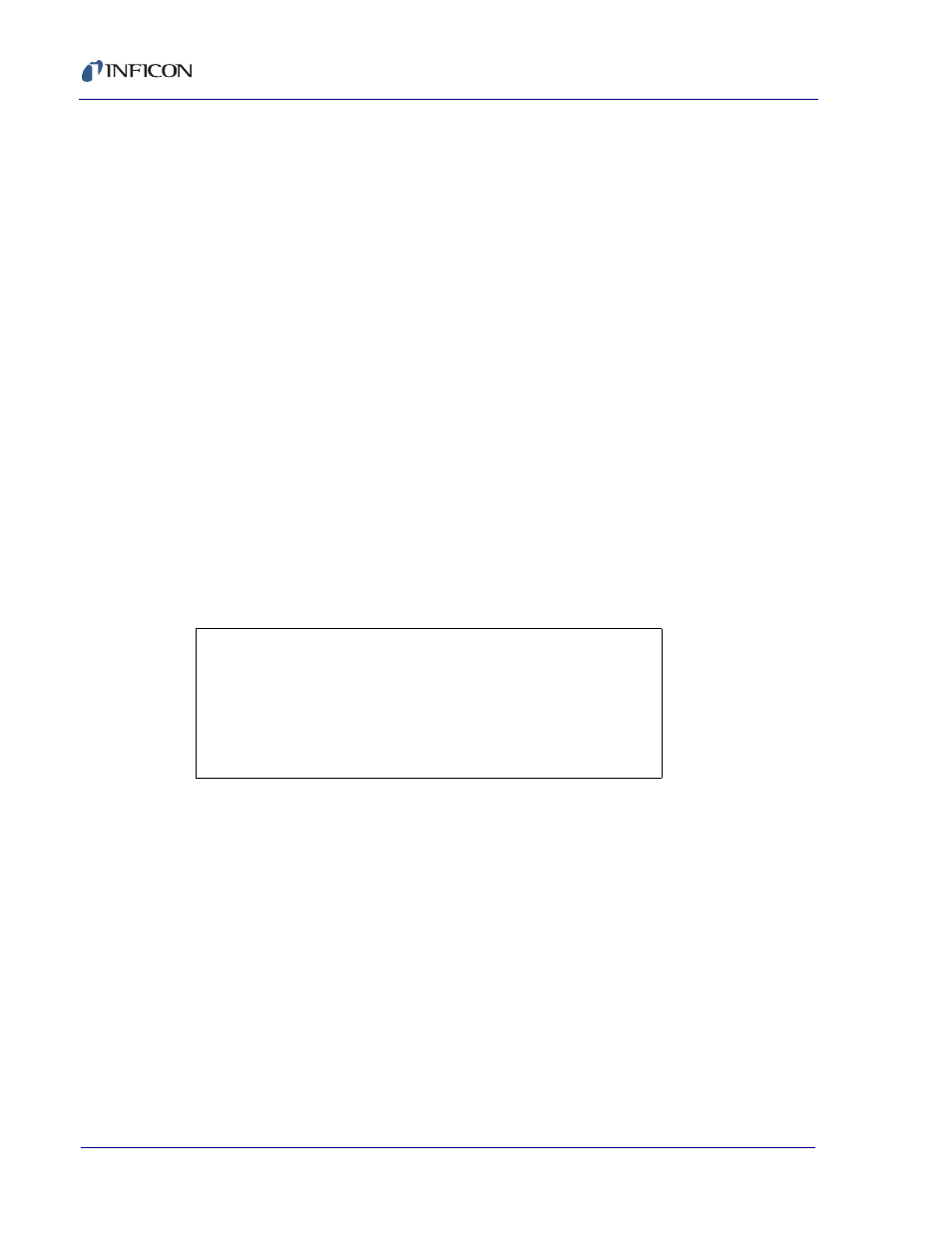

Table 4-5 Representative S and Q Factor Values

SOURCE

MATERIAL

S-FACTOR

Q-FACTOR

2" E-B gun w/liner

Cu

7

7

2" E-B gun

Cu

5

7

1-1/8" E-B gun

Al

4

4

1-1/8" E-B gun

Ni

4

3

Integral W-Al

2

O

3

Cu

6

7