Standard speed compensation (cont’d), 2 speed compensation – Electro Cam PL-1746 Series User Manual

Page 93

5-2 Speed Compensation

Standard Speed Compensation (cont’d)

Calculation

To calculate the amount of speed compensation required, use the following relation-

ships between the transducer's RPM (revolutions per minute) and degrees of rotation:

1 RPM = 360

°

/min = 6

°

/sec = 0.006

°

/msec,

RPM x 0.006 = deg/msec,

thus:

@ 100 RPM, the transducer will rotate 0.6

°

/msec

@ 1000 RPM, the transducer will rotate 6.0

°

/msec

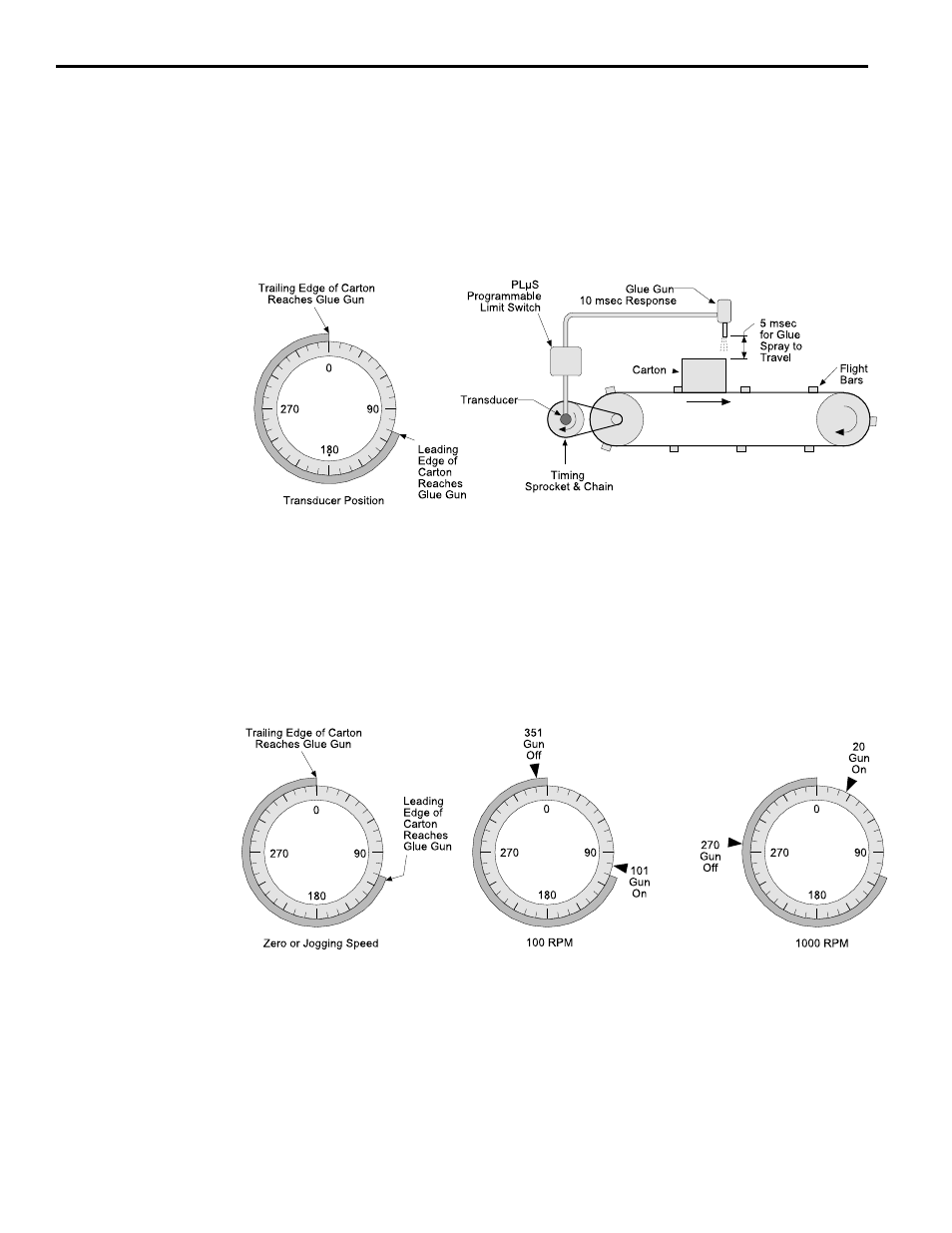

Simple Application Using Speed Compensation

In the previous example, the gluing system requires 15 msec from the time the gun is

energized to the time the glue hits the carton. At 100 RPM, the transducer will rotate

0.6

°

/msec. Therefore, in the 15 msec response time, the transducer will rotate (15 msec

x 0.6

°

), or 9

°

. This means the glue gun must be energized at 101

°

, which is 9

°

before

the box arrives under the gun, and de-energized at 351

°

. At 1000 RPM, the transducer

will rotate (15 msec x 6

°

), or 90

°

during the response time, and the gun must be ener-

gized at 20

°

and de-energized at 270

°

. These values are visually represented in the

illustration below.

Speed Compensation at Various Speeds

Setting Speed Comp

In many applications, speed compensation can be set by jogging the line to determine

ON and OFF edges at zero speed, then entering the speed compensation value into

the controller. In the previous example, the line would be jogged until the leading edge

of the box reaches the gun at 110

°

of transducer rotation. The glue gun output would be

set to turn on at this point. Then, the line would be jogged until the trailing edge is under

the gun at 360

°

, and the glue gun output would be set to turn off.

Once these on and off edges are entered, the glue system response time of 15 msec

would be entered through SPEED COMP programming as described in Chapter 4. As

line speed increases, the PL-1746 will automatically advance the edges to maintain the

accuracy of the glue bead position.