Mode 1 - reset to preset position, 3 groups & modes – Electro Cam PL-1746 Series User Manual

Page 100

6-3 Groups & Modes

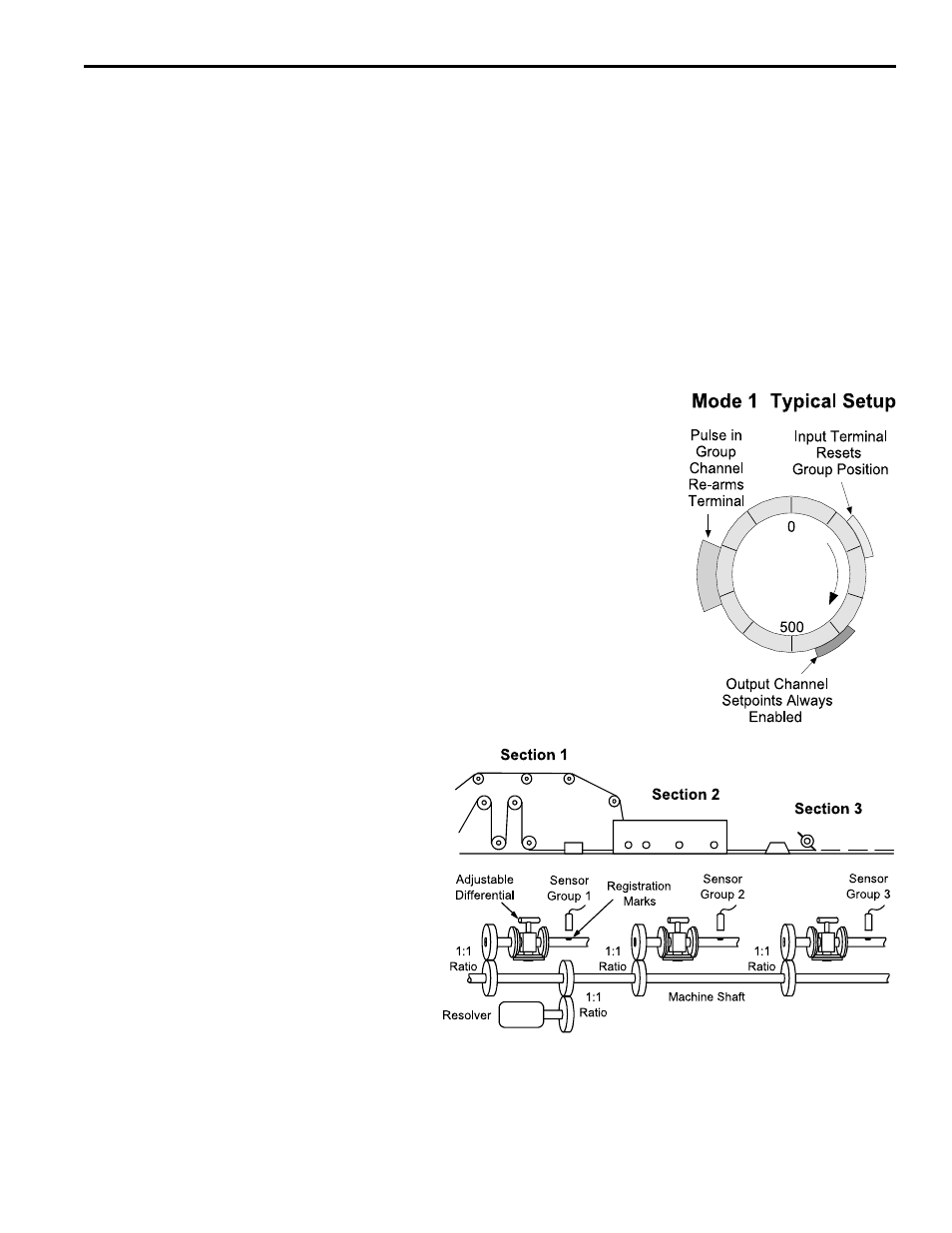

Mode 1 - Reset to Preset Position

Description

Outputs in a group assigned to Mode 1 are always enabled to turn on at their pro-

grammed setpoints. However, when the corresponding input terminal is energized, the

machine position for the group immediately resets to the preset value programmed

through the GROUP OFFSET function. Once the position is reset, the input terminal

will have no effect until it is turned off and the resolver reaches the leading edge of a

pulse programmed into the corresponding group channel.

Applications

This mode can be used to automatically adjust phase relationships between machine

sections. It can also be used in applications where some machine sections run multiple

cycles per resolver revolution.

Details

• The group position resets at the leading edge of the input terminal signal, regardless

of how long the terminal is on.

• Once a reset occurs, the input terminal has no effect until it is de-energized and the

leading edge of a pulse in the corresponding group channel re-arms the terminal.

• When the position of a group resets, the group

channel is affected in the same manner as the

output channels.

• On start-up, the input terminal is armed and the

group position is the same as the value pro-

grammed in MACHINE OFFSET. On power-down,

the group’s current position setting will be lost.

•

If position is increasing as shaft rotates, the “on”

edge of the pulse will re-arm the terminal. If posi-

tion is decreasing as shaft rotates, the “off” edge

of the pulse will re-arm the terminal.

• Each program in the controller can have different

pulses in its output channels and corresponding

group channels.

• MOTION ANDING and OUTPUT ENABLE

ANDING can be used with outputs in a group op-

erating in mode 1.

Mode 1 Example Application

Three sections of an adjustable phase converting

machine are controlled by a single PL

µ

S controller and

resolver. Groups 1, 2 and 3 all operate in Mode 1. The

position of each group is reset to the “preset” value when

the group’s sensor detects the registration mark on the

shaft for the corresponding machine section. This keeps

the electrical control signals properly synchronized to

the mechanical devices in each section when phase

adjustments are made.

One resolver provides the position information needed

for all sections of the machine, regardless of their phase

relationship.

Mode 1 Programming

1. Program OUTPUT GROUPS to establish groups and modes.

2. Program the preset value for the group using GROUP OFFSET.

3. Jog the machine to the point where the group input terminal will energize. Using this

point as a reference, program pulses into the group’s output channels.

4. Program a pulse in the group channel.