Standard axle lift cylinder repair – Alamo HYDRO 15 User Manual

Page 95

Section 5 - 21

HYDRO 15 (Service Manual) 10/06

© 2006

Alamo Industrial

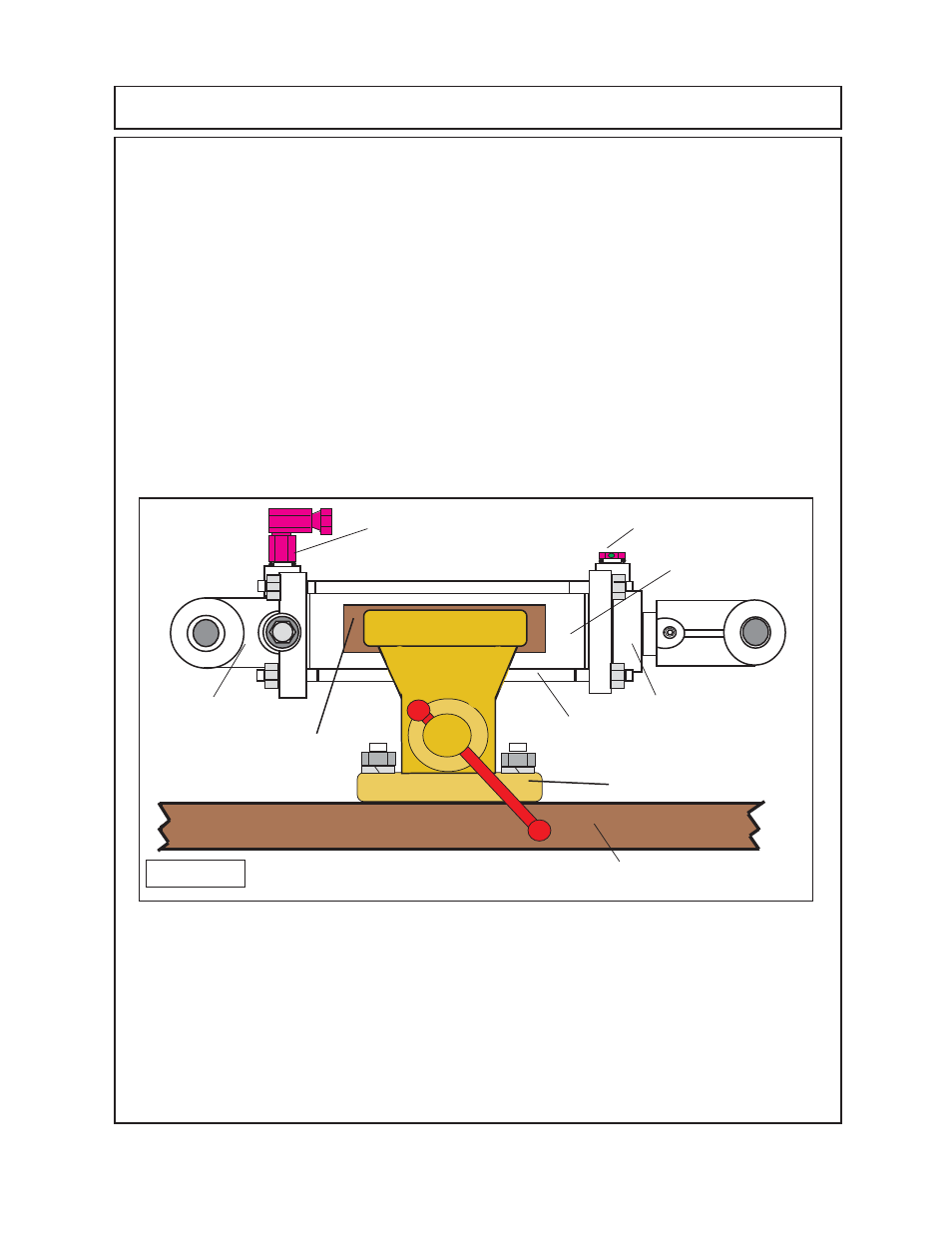

STANDARD AXLE LIFT CYLINDER REPAIR

8.

Install the new nylon thread protector

(figure 6 item 2)

into the cylinder rod clevis

(figure 6 item

3)

, Make certain the nylon thread protector is laying flat in the bottom of the threaded hole in the

clevis. Insert the setscrew

(figure 6 item 2)

into the clevis

(figure 6 item 3)

. Tighten the clevis

setscrew to

20 ft. lbs

(base on 3/8” setscrew).

9.

Coat the cylinder base barrel seals

(figure 6 & 9 item 8)

with coat of hydraulic oil. Install the

cylinder base end into the barrel

(see figure 9)

. If plastic plug is installed in base end as shown

(see

figure 9)

it will allow the insertion of the base end into the barrel if plug is removed. Make certain

that the ports on the base end are aligned with thew cylinder head as shown

(see figure 9 item 8

& 9)

, the ports

must be aligned

this way.

10

Install cylinder tie-rods

(figure 9 item 6 & 7)

, make certain that the hex nuts that were left on

the tie-rod is loose. Insert the tie- rods

(qty 4)

and the hex nuts

(qty 8)

onto the tie-rods. The hex

nuts must be screwed on at the same rate and on each end, try to keep the same amount of threads

sticking out the nuts on both ends of the tie-rods. Snug the nuts down an all 4 tie rod evenly and

alternating as to keep the same amount of pressure evenly. Torque the tie-Rod nuts to

80 ft. lbs

(based on a 1/2” tie-rod).

11.

Install the vent plug into the cylinder head port

(figure 9 item 9)

at the Rod End of cylinder.

Install the hydraulic elbow adapter to the base end of cylinder

(figure 9 item 8)

. Note; plug the open

end of the hydraulic adapter until time to connect the hose to it.

1234

1234

1234

1234

Figure 9

Wood or other soft

material

Bench Vise

Work Bench

9

(cyl head, clevis, cyl

rod & piston asy).

5

8

12

12

12

12

1234

1234

1234

1234

12

12

12

12

12

6 & 7

123

123

123

123

123

123

12

12

12

12

12

12

1234

1234

1234

Vent Plug

Hydraulic Elbow

Adapter

12.

Install the cylinder onto mower, Mount the cylinder with the base end

(figure 9 item 8)

to the

deck lug. Mount the cylinder head / rod end

(figure 9 item 9)

of the cylinder to the axle lug. When

first using the rebuilt and/or new cylinder it is not unusual for a light amount of oil to be pushed

out of the vent. The amount is the amount that was used to oil components during assembly.

If excessive amount leaks through the vent, cylinder is not functioning properly. Recheck the

assembly steps for possible assembly error.